Multi-specification ceramic mud stacking device

A multi-specification, ceramic technology, applied in the direction of the supply device, ceramic molding machine, ceramic extrusion die, etc., can solve the problems of poor quality of columnar porcelain clay, inability to produce columnar porcelain clay, lack of practicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

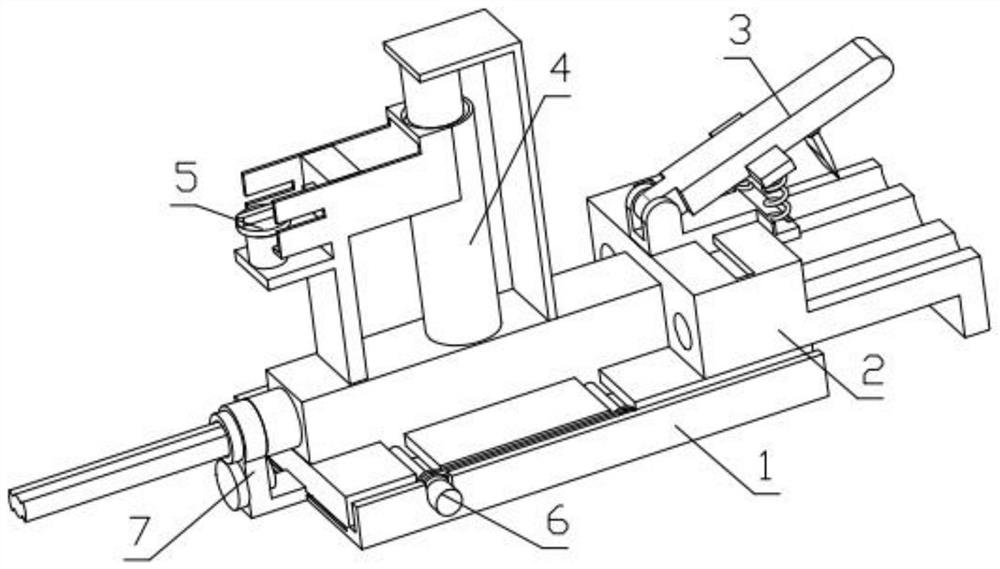

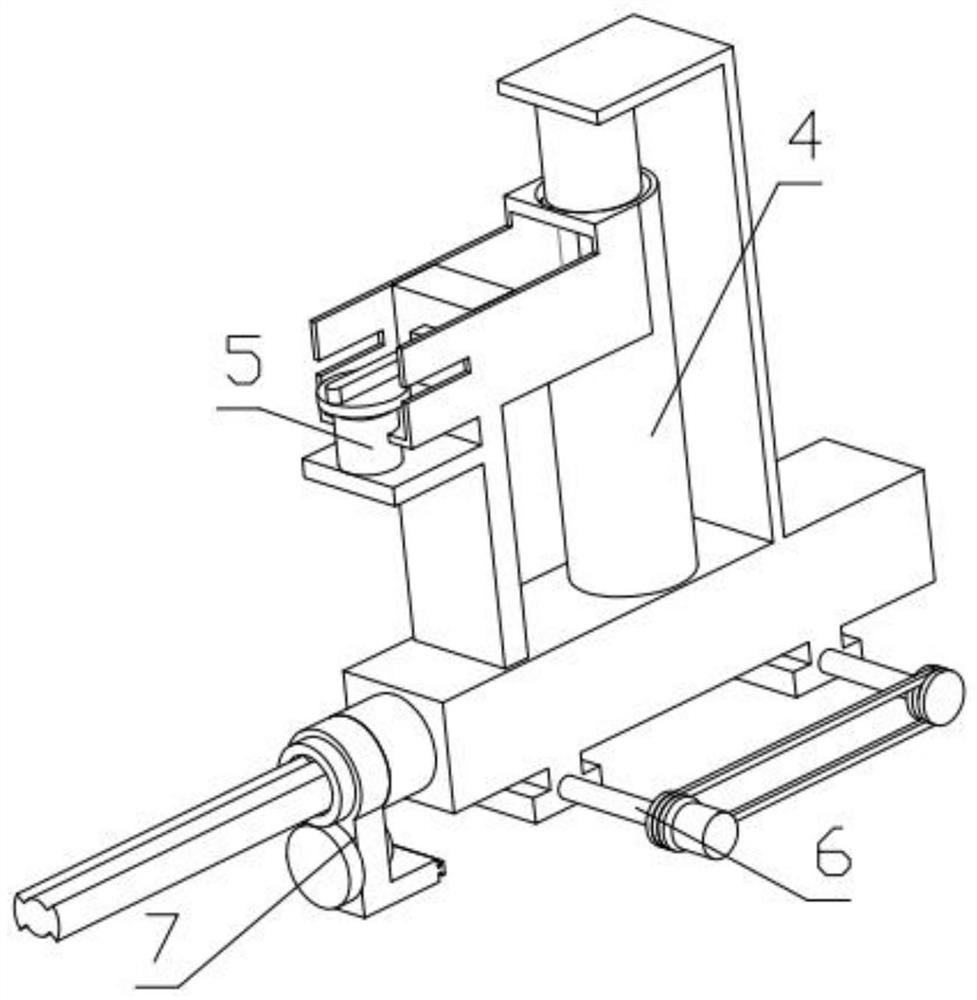

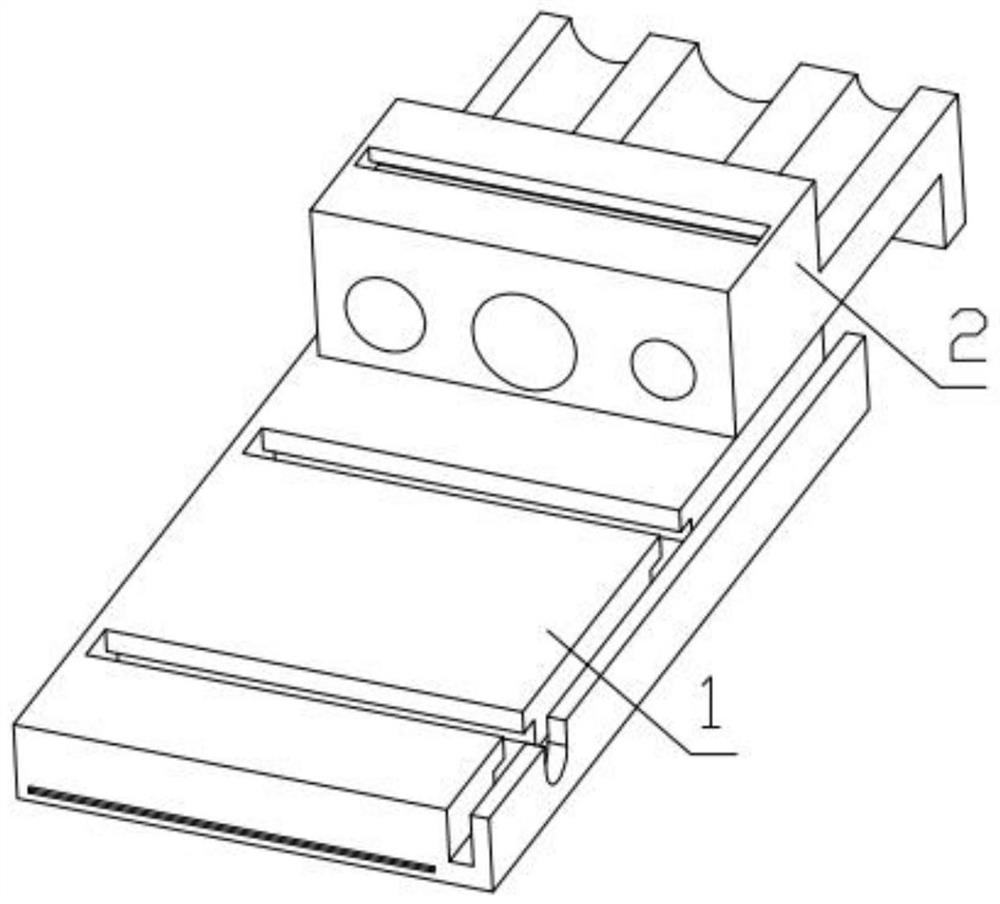

[0037] Combine below Figure 1-12 Describe this embodiment, a multi-standard ceramic clay stacking device, including a base plate 1, a multi-standard shelf plate 2, a free cutting mechanism 3, a clay input mechanism 4, a pushing mechanism 5, a position adjustment mechanism 6 and compaction and extrusion Mechanism 7, the multi-standard frame plate 2 is fixedly installed on the base plate 1, the free cutting mechanism 3 is slidably installed in the groove provided by the multi-standard frame plate 2, and the clay input mechanism 4 is slidably installed on the base plate 1. In the groove, the position adjustment mechanism 6 is fixedly installed on the base plate 1, the clay input mechanism 4 is threadedly connected with the position adjustment mechanism 6, and the compacting and extruding mechanism 7 is slidably installed in the groove provided on the base plate 1, compacting And the extruding mechanism 7 is slidingly installed in the clay input mechanism 4, the pushing mechanism...

specific Embodiment approach 2

[0039] Combine below Figure 1-12 Describe this embodiment, this embodiment will further describe the first embodiment, the free cutting mechanism 3 includes a sliding base 3-1, a swing arm 3-2, an L-shaped pallet 3-3, a support spring 3-4, a sliding Part 3-5, cutting knife 3-6, sliding base 3-1 is slidably installed in the groove provided on the multi-standard frame plate 2, L-shaped supporting plate 3-3 is fixedly installed on the sliding base 3-1, and the supporting spring One end of 3-4 is fixedly installed on the L-shaped supporting plate 3-3, the other end of the support spring 3-4 is fixedly installed on the swing arm 3-2, and the swing arm 3-2 is hinged on the sliding base 3-1, sliding The part 3-5 is slidably installed in the groove provided on the swing arm 3-2, and the sliding part 3-5 is fixedly connected with the cutting knife 3-6.

specific Embodiment approach 3

[0041] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the first embodiment, the clay input mechanism 4 includes a vertical plate 4-1, a square hole 4-2, a cylinder frame 4-3, and an output motor 4-4 , spiral fan blade 4-5, the spiral fan blade 4-5 is fixedly installed on the output end of the output motor 4-4, the output motor 4-4 is fixedly installed on the vertical plate 4-1, and the vertical plate 4-1 is fixedly installed on the square On the round hole part 4-2, a cylinder frame 4-3 is fixedly installed on the square hole part 4-2, and a spiral fan blade 4-5 is installed in the rotation of the cylinder frame 4-3, and the square hole part 4-2 Slidingly installed in the groove provided on the base plate 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com