Synchronous opening and closing bottle outflow connecting line mechanism

A connection and curve technology, applied in the field of synchronous opening and closing bottle-out connection mechanism, can solve problems such as difficulty in ensuring synchronization in place, inconsistent resistance between the air source and its own sealing ring when starting and stopping synchronously, and poor dimensional stability of the guide rail pair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

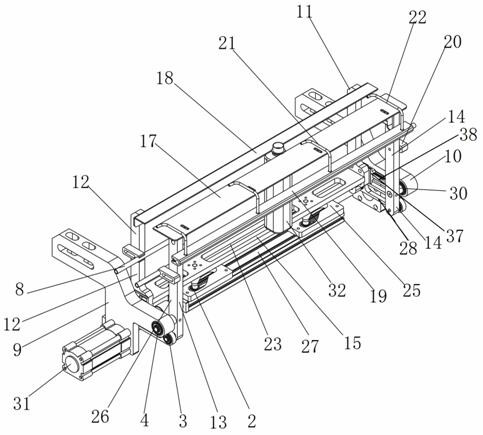

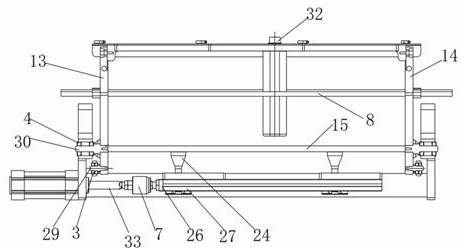

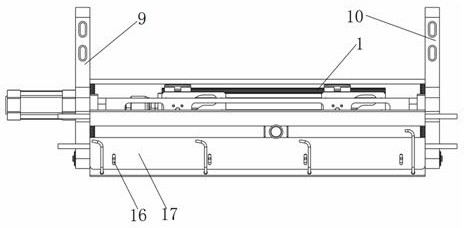

[0039] Hereinafter, the present invention will be described in detail with reference to examples and drawings.

[0040] refer to Figure 1 to Figure 5 , the present invention provides a synchronous opening and closing bottle outlet connection mechanism, including

[0041] a set of corresponding left fixing plate 12 and right fixing plate 11,

[0042] The cylinder 31 is arranged at the bottom of the left fixed plate 12, the cylinder push rod 33 is fixed with the guide rail holder 2 through the floating joint 7, and the floating joint 7 and the guide rail holder 2 are connected by the floating head fixing block 26,

[0043] A group of opening and closing track plates are respectively fixed on the left and right ends of the guide rail holder 2 top, each opening and closing track plate is provided with an opening and closing guide rail 36, and an opening and closing guide shaft 24 is arranged in each opening and closing guide rail 36, so that The upper part of the opening and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com