Packing machine bag opening device

A technology of machine bag opening and packaging machine, applied in packaging and other directions, can solve the problems of heavy workload, unsmooth opening of bags, and high energy consumption, and achieve the effect of reducing workload, quantity and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

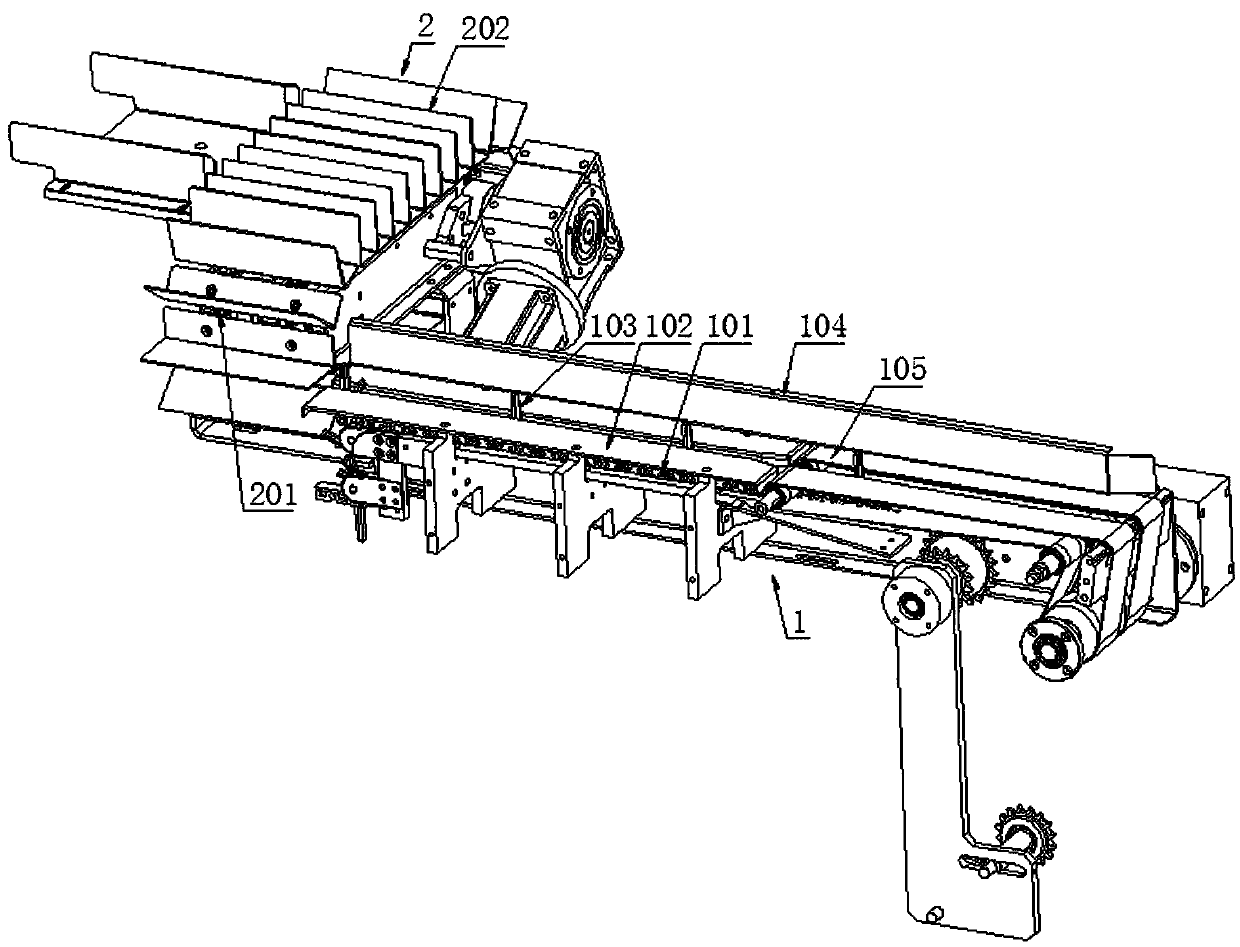

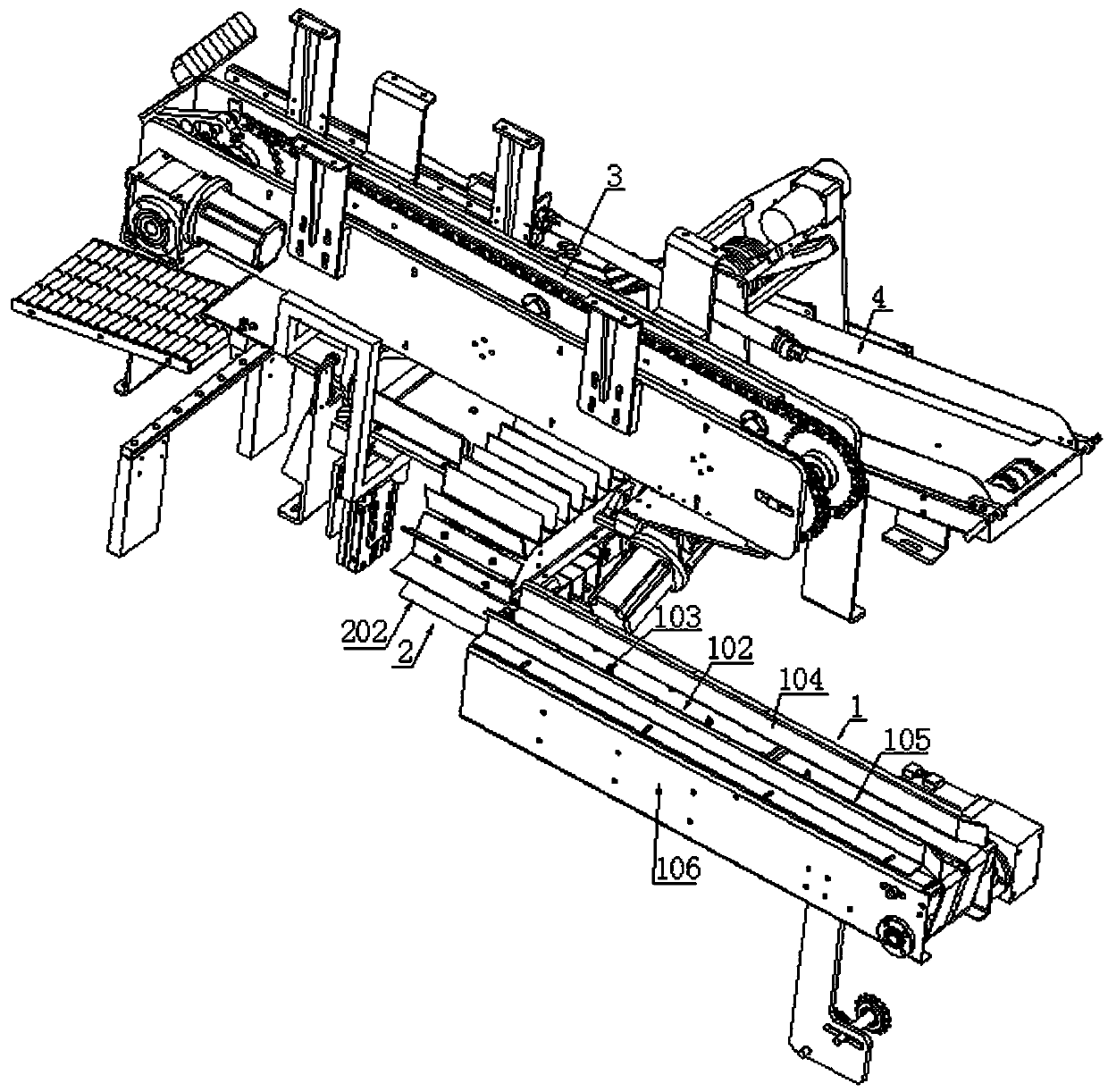

Embodiment 1

[0052] This embodiment provides a bag receiving and stretching device for a packaging machine. The bag receiving and stretching mechanism 7 includes a bag receiving and conveying mechanism 5 and a bag stretching mechanism 7. The bag receiving and conveying mechanism 5 includes a bag receiving plate 501 and a bag receiving plate that can 501 is a translation mechanism that reciprocates between the bag receiving station 505 and the bag opening station, and an adsorption hole 503 is opened on the side of the bag receiving plate 501 corresponding to the opening of the prefabricated bag; the bag opening mechanism 7 includes a bag opening claw 701. The sides of the bag claw 701 are arc-shaped. The role of the adsorption hole 503 is to absorb the mouth of the prefabricated bag at the bag receiving station 505, fix the prefabricated bag on the bag holder plate 501, and absorb the lower side of the mouth of the prefabricated bag at the bag opening station to cooperate with the suction c...

Embodiment 2

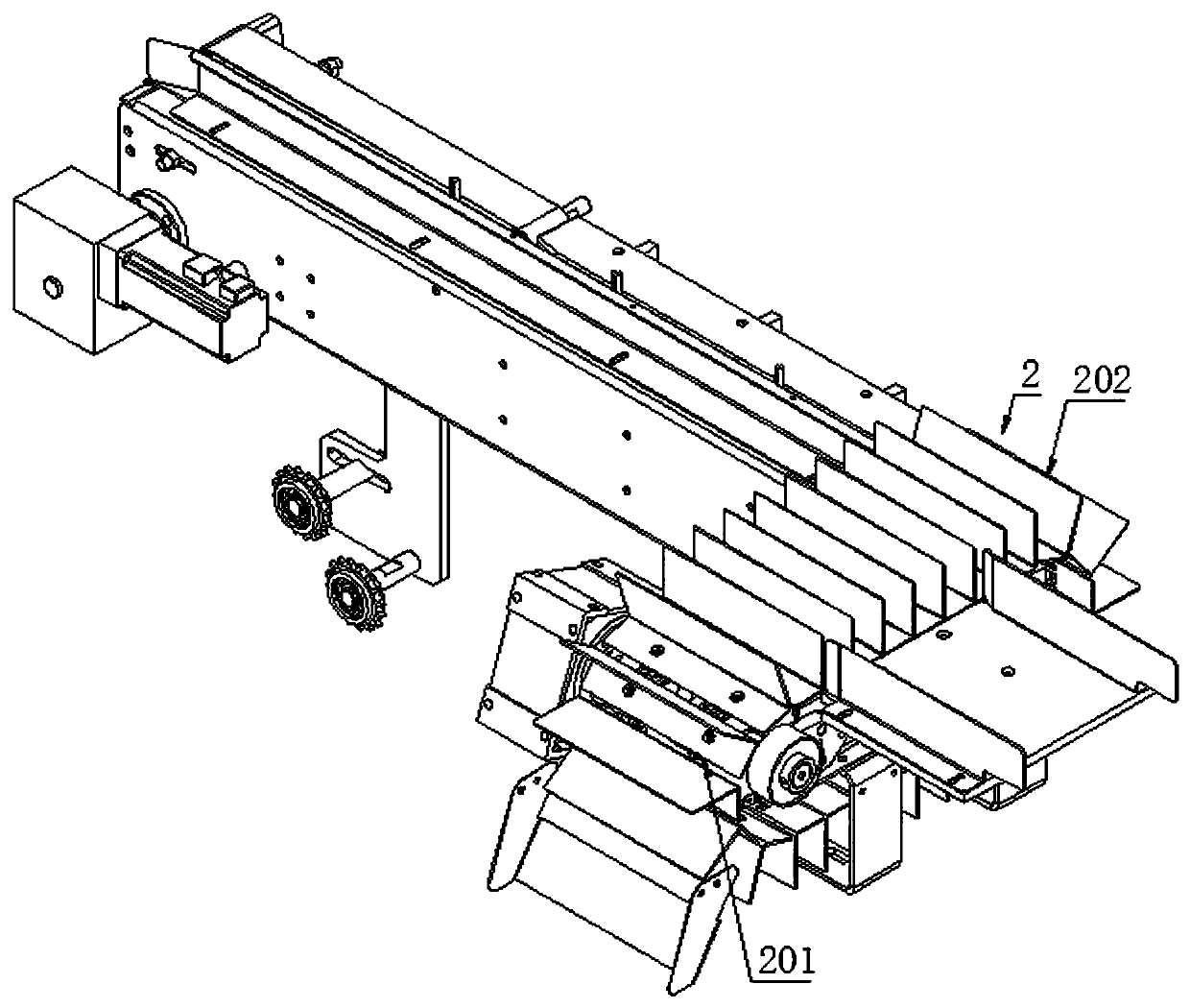

[0061] This embodiment provides a bag receiving and conveying mechanism 5 of a packaging machine, through the function of the bag receiving and conveying mechanism 5, the bag receiving and conveying action of prefabricated bags is realized, and the specific structure is as follows:

[0062] The bag receiving conveying mechanism 5 includes a bag receiving plate 501 and a translation mechanism that enables the bag receiving plate 501 to reciprocate between the bag receiving station 505 and the bag opening station. There are adsorption holes 503;

[0063] The translation mechanism includes a power source and a guide 502 , the pocket plate 501 is movably mounted on the guide 502 , and the power source drives the pocket plate 501 to move on the guide 502 .

[0064] Both sides of the guide 502 are provided with arc-shaped grooves 504, and the arc-shaped grooves 504 are arranged along the length direction of the guide 502, and the lower surface of the pocket plate 501 is provided wit...

Embodiment 3

[0066] This embodiment provides a bag receiving and conveying mechanism 5 of a packaging machine, through the function of the bag receiving and conveying mechanism 5, the bag receiving and conveying action of prefabricated bags is realized, and the specific structure is as follows:

[0067] The bag receiving conveying mechanism 5 includes a bag receiving plate 501 and a translation mechanism that enables the bag receiving plate 501 to reciprocate between the bag receiving station 505 and the bag opening station. There are adsorption holes 503;

[0068] The translation mechanism includes a power source and a guide 502 , the pocket plate 501 is movably mounted on the guide 502 , and the power source drives the pocket plate 501 to move on the guide 502 .

[0069] The upper surface of the guide 502 is provided with a bar-shaped groove, and the bar-shaped groove is arranged along the length direction of the guide 502. The lower surface of the pocket plate 501 is provided with a bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com