A motorcycle brake pedal and its processing technology

A technology of brake pedal and processing technology, which is applied to bicycle brakes, bicycle accessories, coatings, etc., can solve the problem that the surface of motorcycle brake pedals is easily corroded, and achieve reduced moisture and oxygen penetration and good anti-corrosion effects , good oxidation resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The application discloses a motorcycle brake pedal and its processing technology. A motorcycle brake pedal includes a plate body, and the processing technology includes the following steps:

[0038] S1. Preparation of anti-corrosion coating; weigh the required components, fully mix polybutadiene epoxy resin, 4-chloro-3-nitro-5 chlorosulfonylbenzoic acid and o-xylene, and heat up to 100°C , stirred and reacted for 1 hour, then added acrylic resin and film-forming aid 1-butoxyl-2-propanol, mixed evenly, stirred and reacted for 30 minutes, and cooled to room temperature to obtain an anti-corrosion coating;

[0039] S2. Spray anti-corrosion coating; wipe the debris or dust on the surface of the board, immerse the wiped board into the anti-corrosion coating of S1, take it out after standing for 3s, and irradiate it under 8um infrared rays for 3min, then put the board The body was dried at a temperature of 120°C.

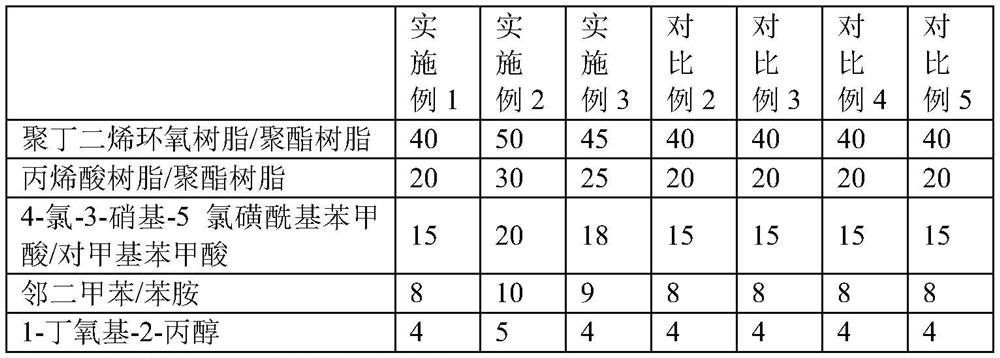

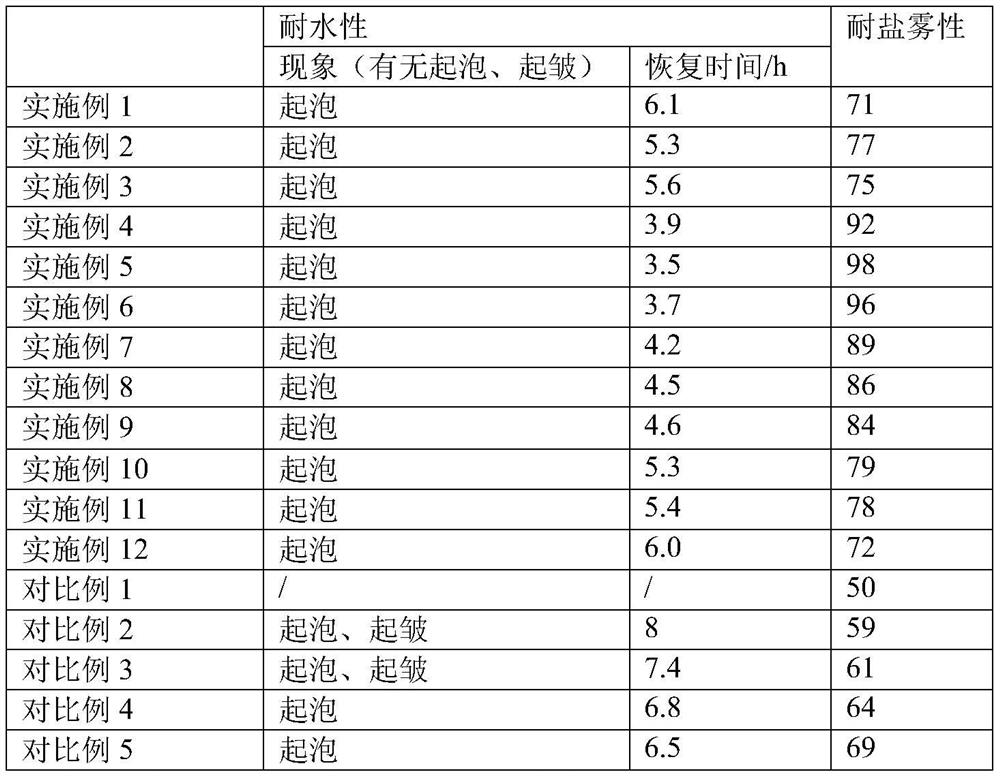

[0040] The content of each component of the anti-corrosion c...

Embodiment 2

[0042] The application discloses a motorcycle brake pedal and its processing technology. A motorcycle brake pedal includes a plate body, and the processing technology includes the following steps:

[0043] S1. Preparation of anti-corrosion coating; weigh the required components, fully mix polybutadiene epoxy resin, 4-chloro-3-nitro-5 chlorosulfonylbenzoic acid and o-xylene, and heat up to 110°C , stirred and reacted for 1.5h, then added acrylic resin and film-forming aid 1-butoxyl-2-propanol, mixed evenly and stirred for 40min, cooled to room temperature to obtain an anti-corrosion coating;

[0044]S2. Spray anti-corrosion coating; wipe the debris or dust on the surface of the board, immerse the wiped board into the anti-corrosion coating of S1, take it out after standing for 4s, and irradiate it under 10um infrared rays for 4min, then put the board The body was dried at a temperature of 140°C.

[0045] The content of each component is shown in Table 1 below.

Embodiment 3

[0047] The application discloses a motorcycle brake pedal and its processing technology. A motorcycle brake pedal includes a plate body, and the processing technology includes the following steps:

[0048] S1. Preparation of anti-corrosion coating; weigh the required components, fully mix polybutadiene epoxy resin, 4-chloro-3-nitro-5 chlorosulfonylbenzoic acid and o-xylene, and heat up to 105°C , stirred and reacted for 1.5h, then added acrylic resin and film-forming aid 1-butoxyl-2-propanol, mixed evenly, stirred and reacted for 35min, cooled to room temperature, and an anti-corrosion coating was obtained;

[0049] S2. Spray anti-corrosion coating; wipe the debris or dust on the surface of the board, immerse the wiped board into the anti-corrosion coating of S1, take it out after standing for 3s, and irradiate it under 9um infrared rays for 3min, then put the board The body was dried at a temperature of 130°C.

[0050] The content of each component is shown in Table 1 below....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com