Large-overload shock absorber

A shock absorber and large overload technology, applied in the direction of non-rotational vibration suppression, low internal friction springs, etc., can solve the problems of excessive coaxiality between the output shaft of the engine and the input shaft of the final reducer, potential safety hazards, and easy damage to rubber materials , to achieve good vibration reduction effect and good limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

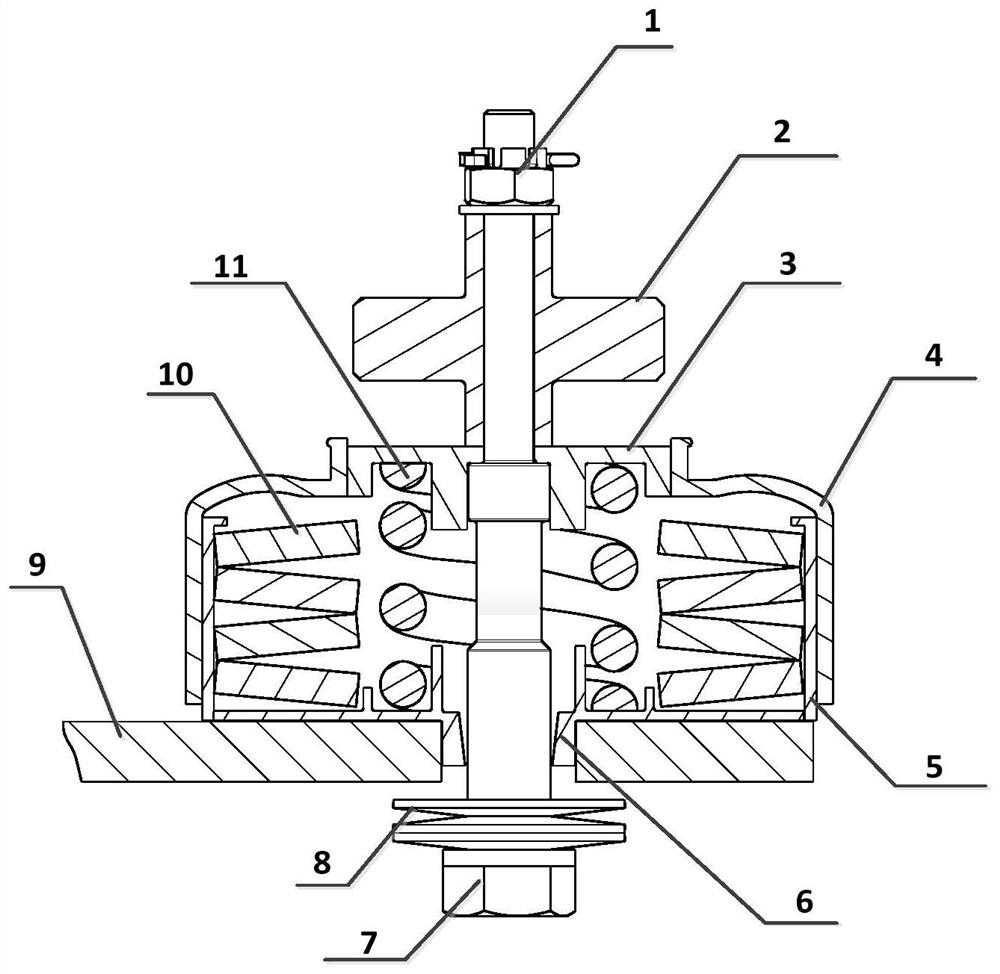

[0027] Embodiments of the present invention provide a large overload shock absorber, such as figure 1 As shown, it includes: nut 1, bearing joint 2, shock absorber upper positioning part 3, shock absorber outer shell 5, shock absorber lower positioning part 6, special bolt 7, first disc spring 8, second disc spring 10, compression spring 11;

[0028] Among them, the middle part of the special bolt 7 is provided with a first boss; the load-bearing joint 2 and the upper positioning part 3 of the shock absorber are pressed on the first boss of the special bolt 7 through the nut 1;

[0029] The lower positioning part 6 of the shock absorber is fixed on the structural frame 9 of the helicopter body, and the lower part of the special bolt 7 passes through the lower positioning part 6 of the shock absorber;

[0030] The corresponding positions on the shock absorber upper positioning part 3 and the shock absorber lower positioning part 6 are respectively provided with grooves;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com