Starter Planetary Gear Straightening and Lubricating Device and Its Application Method

A planetary gear and lubricating device technology, applied in the field of auto parts, can solve the problems of affecting production efficiency, increasing the labor intensity of operators, poor grease injection position, etc., and achieve the effects of improving efficiency, saving manpower, and reducing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

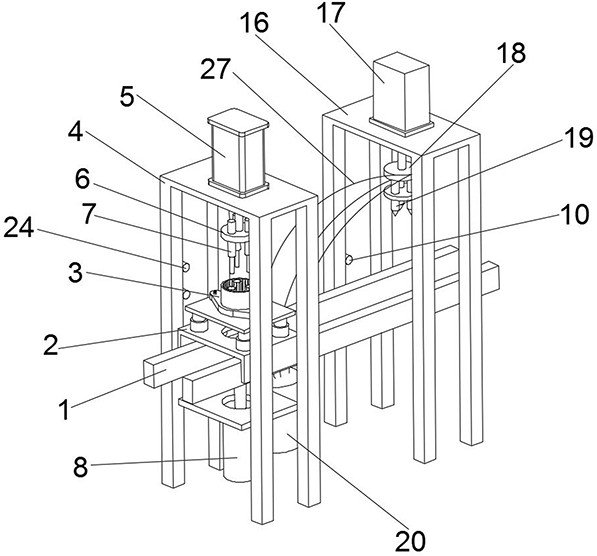

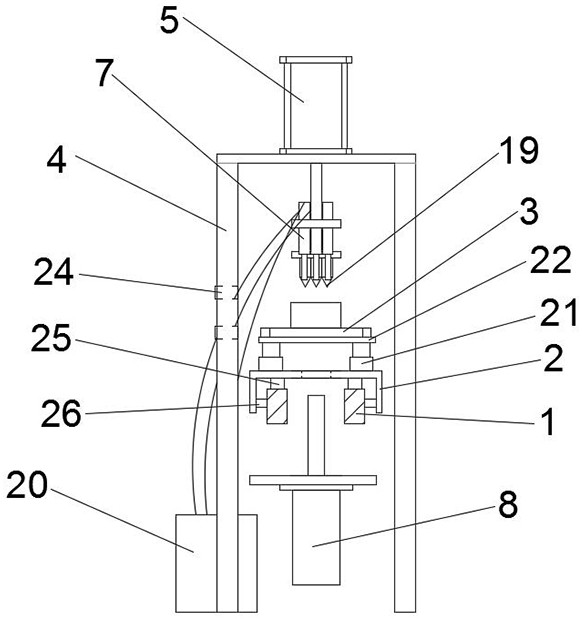

[0028] Such as Figure 1-4 As shown, a starter planetary gear straightening lubrication device includes a transmission part, a straightening part, a lubrication part and a control system; the transmission part includes a conveying track 1 and a conveying seat 2; the lower part of the conveying seat 2 is provided with The moving mechanism, the conveying seat 2 is movable on the conveying track 1 through the moving mechanism; the planetary gear tooling 3 that needs to be corrected by the planetary gear is detachably fixed on the conveying seat 2; the conveying seat 2 is provided with a lift escape hole;

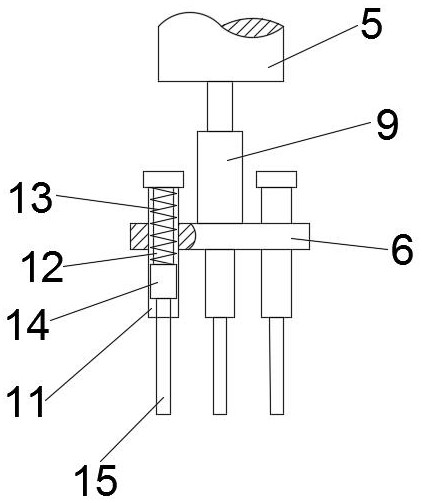

[0029] The straightening part includes a gate-shaped bracket I4, a servo motor 5, a telescopic straightening rod 7 and a cylinder 8; the gate-shaped bracket I4 is arranged across the conveying track 1; the rotor of the servo motor 5 is set on the The top of the door-shaped bracket I4; the three sets of telescopic straightening rods 7 are distributed at the end of the rotor of ...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that: the front end of the push rod of the electric cylinder 17 is provided with a disk 18 ; the grease nozzles 19 are distributed and connected to the disk 18 .

[0042] The usage method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 2 is that: there are at least two groups of photoelectric sensors I 24 ; the two groups of photoelectric sensors I 24 are arranged vertically.

[0045] The usage method of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com