Telescopic workbench

A workbench and telescopic technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of production process change and low production efficiency, and achieve the effect of improving production efficiency and fast and efficient process arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, further elaborate the present invention.

[0032] The orientations involved in this specification are all based on the normal working orientation of the telescopic workbench of the present invention, and are not limited to its orientation during storage and transportation, and only represent relative positional relationships, not absolute positional relationships.

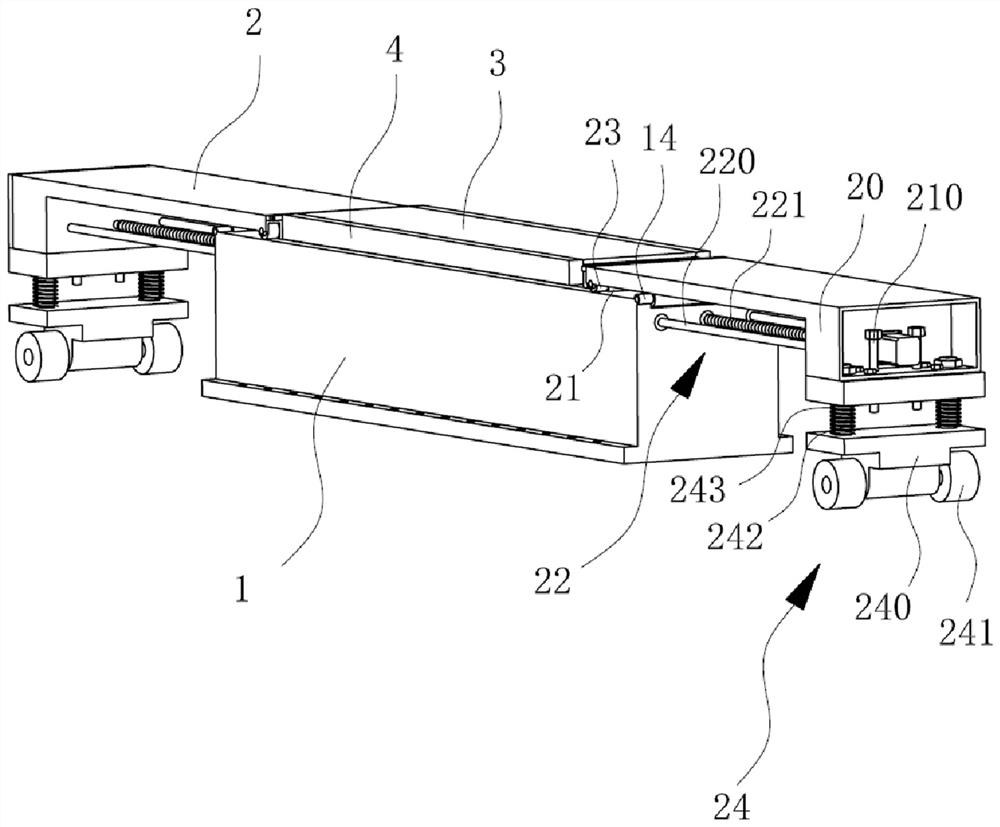

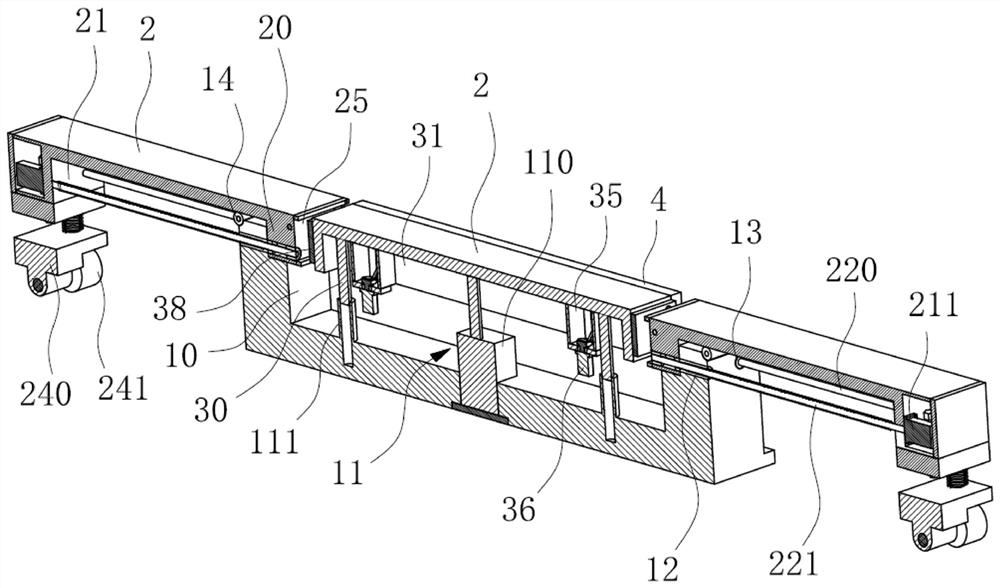

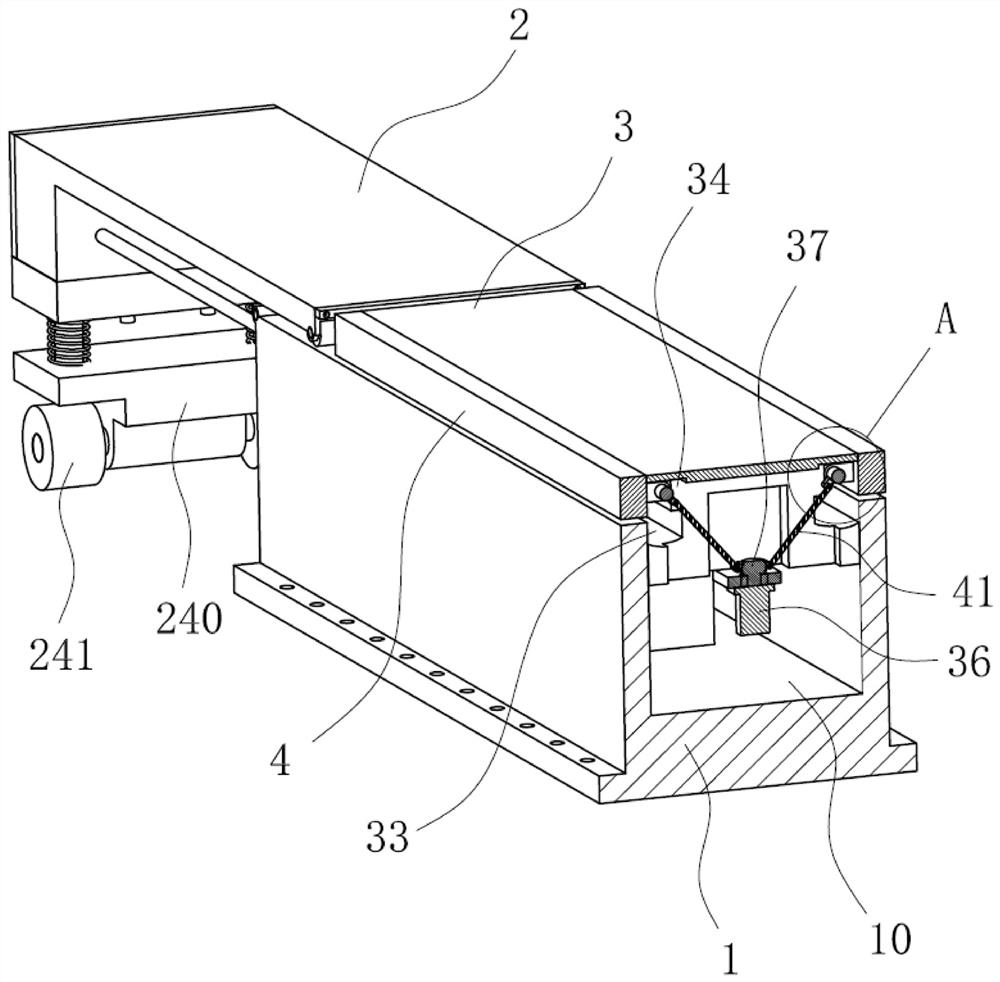

[0033] Such as figure 1 , figure 2 , image 3 as well as Figure 4 As shown together, the telescopic workbench includes a fixed seat 1, which is used to fix on the ground position, and two translation platforms 2 that move toward or back are installed on the fixed seat 1, and the relative displacement of the two translation platforms 2 That is to realize the expansion and contraction of the workbench.

[0034] The bottoms at both ends of the translation platform 2 are respectively fixed with a first support block 20 and a second support block 21, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com