Large cruise ship sheet block internal temporary supporting method

A temporary support and large-scale technology, applied in the direction of ships, etc., can solve the problems of no strong structure and long natural period in sections, and achieve the effect of reducing waste and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

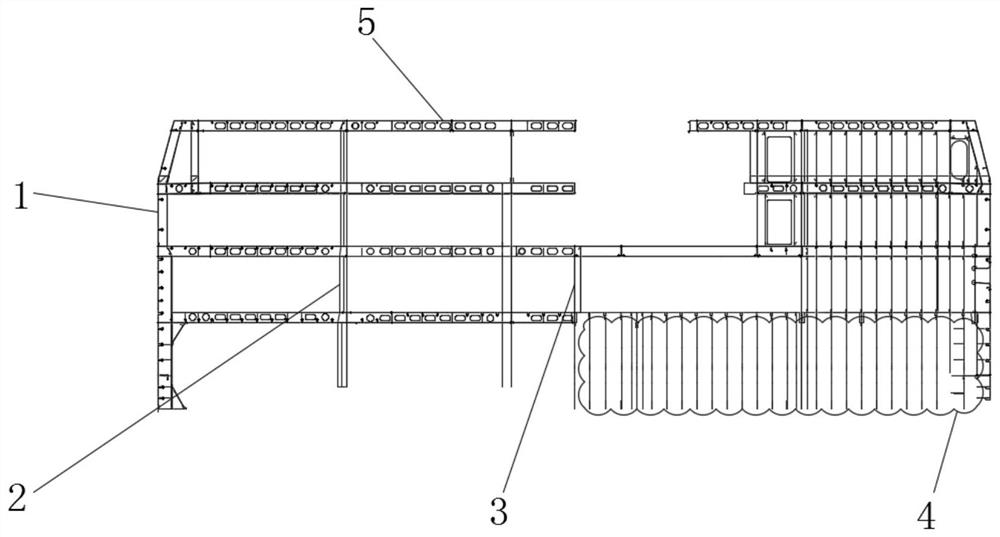

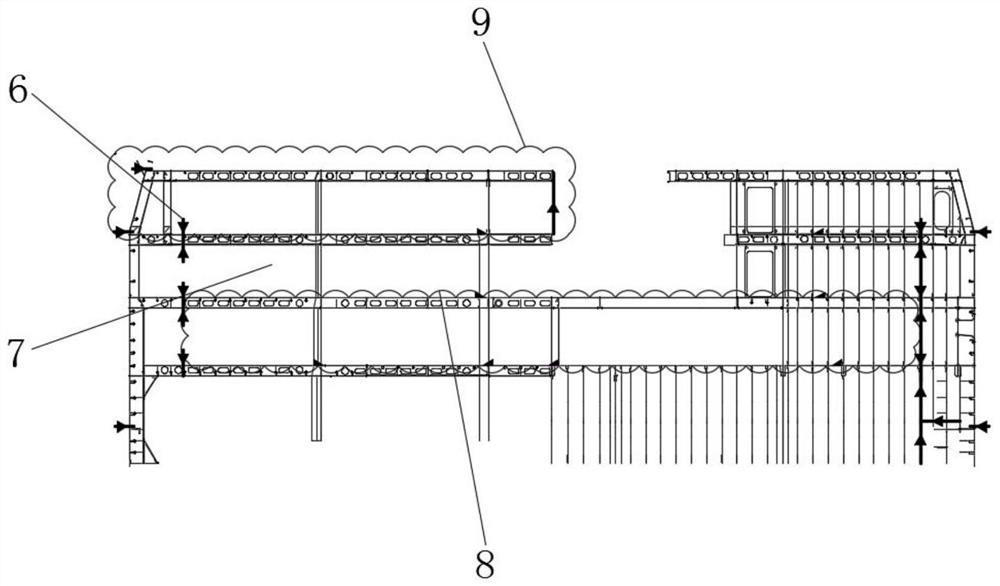

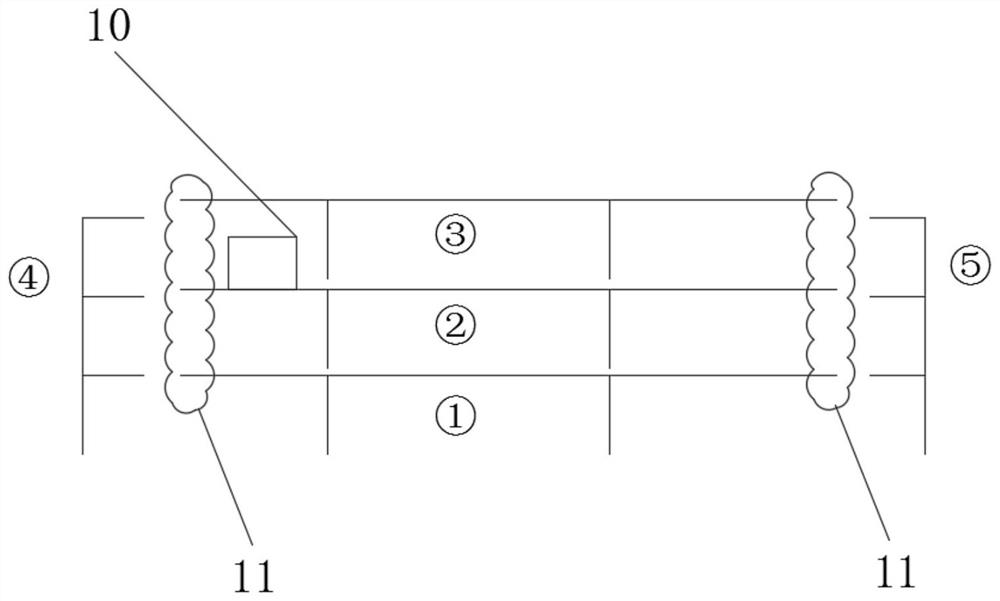

[0029] see Figure 1-6 ,本实施例提供了大型邮轮薄板总段内部临时支撑方法,包括如下步骤:

[0030] 中间全宽型甲板分段的左右两侧:因为外板分段参与总组较晚,中间全宽型甲板分段从下往上总组成多层甲板总段,所以该分段左右两侧长时间处于自由状态,在结构特点方面,往往前后左右8m范围内无立柱2、舱壁、围壁结构进行上下支撑,且该区域的薄板甲板板架5相对较弱,设置内部临时支撑进行上下连接,确保上方甲板不会沉降,直到外板结构总组完成后,才进行临时支撑拆除。

[0031] 带外板半宽型分段9之间:某类总段的多层甲板,都采取这种划分方式,单层甲板的左右分段之间,甲板面下方的结构自身支撑结构可能较少, 在后总组分段的总组之前,以总组的分段的船中位置处于自由状态,必须设置必要的内部临时支撑进行上下连接,直到左右分段都总组完成后,才进行临时支撑 tear down.

[0032] 甲板面大型舾装的下方:部分大型舾装设计在分段左右首尾的自由边位置,带来甲板沉降问题并影响舾装准确安装,在大型舾装的甲板下方,设置必要的内部临时支撑进行上下连接,直到总组后期或者船坞阶段大型舾装设备四周具备上下强结构,才进行临时支撑拆除。

[0033] 总段首尾端面:总段首尾端面往往没有完整的全幅面舱壁结构,或者立柱2结构数量不足,因薄板总段采用大型吊车进行船坞吊装,其吊点往往距离首尾端面有一定距离,加上总段层数较多,为了确保总段首尾端面的整体刚度,并避免变形给船坞总段之间合拢作业带来困难,必须确保保证首尾端面的结构精度,在首尾端面各层甲板之间,设置必要的内部临时支撑,直到总段船坞吊装结束,才进行临时支撑拆除。

[0034] 支撑结构均选用圆管15型材,且圆管15的两端各设置有四块肘板14用于上下连接焊接,仅仅肘板14连接,圆管15不连接。

[0035] 圆管15型材直径60mm-100mm,壁厚6-10mm,φ80mm×8mm圆管15 2.5m长,其重量35kg,相比其他常用建造用型材,重量轻了接近40%,这样拆除后更方便从邮轮结构内部运输到外部进行回收,提高作业效率,否则太重,往往进行切断进行运输,造成整根回收不便,同时,太重或者进行切断,可能在拆除及运输过程中碰撞薄板结构,造成破坏。

[0036] 肘板14规格100mm-300m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com