Gantry crane steel wire rope connecting piece and connecting method

A technology of connectors and steel wire ropes, which is applied in the direction of load suspension components, transmission components or pulley ropes or cables, belts/chains/gears, etc., which can solve the problems of wire rope wear, high cost, and time required to replace wire ropes, etc., to avoid Effect of friction and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

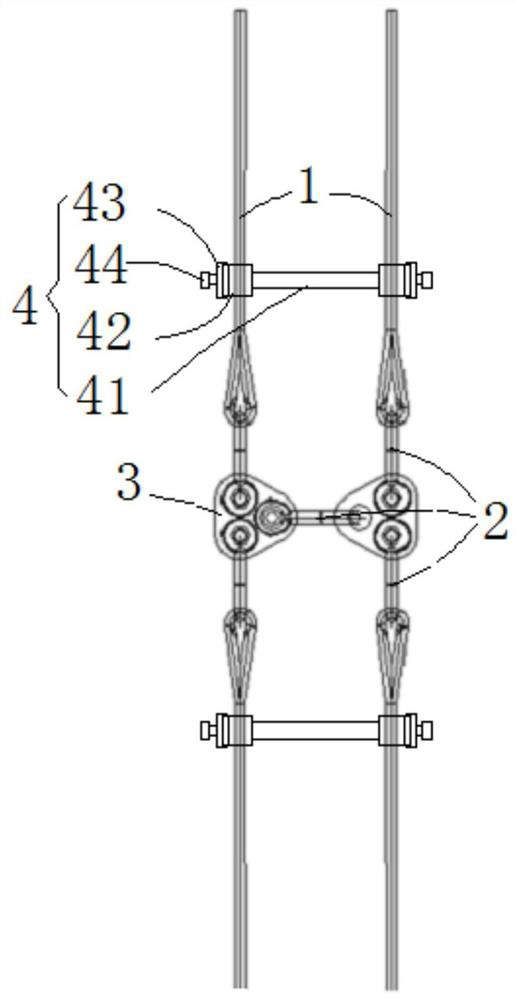

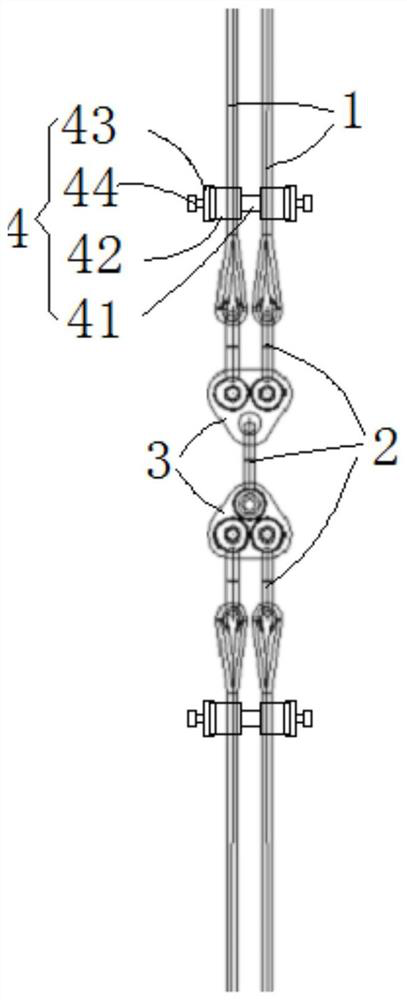

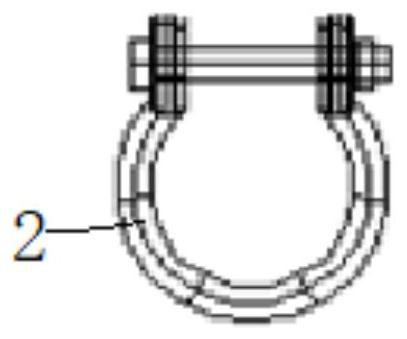

[0029] see Figure 1-6 , this embodiment provides a gantry crane wire rope connector, including four wire ropes 1, two connectors 3 and several shackles 2, the four wire ropes 1 are divided into two groups, and the two wire ropes 1 of each group are up and down Yes, each connecting piece 3 includes a connecting piece main board 31, and each connecting piece main board 31 is provided with three connecting holes 33 distributed in an equilateral triangle, and each connecting piece 3 is respectively located between the upper and lower two steel wire ropes 1, and One end of each steel wire rope 1 that is close to each other is snapped into the inner cavity of the connecting hole 33 of the connector main board 31 through the shackle 2, and the two connector main boards 31 are snapped together by the shackle 2 between two adjacent connector main boards 31. Close to the connecting...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap