Garment processing ironing device

A clothing and ironing technology, which is applied in the field of clothing processing and ironing devices, can solve problems such as steam waste, safety hazards, hand crushing, etc., and achieve the effects of improving safety performance, reducing waste, and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

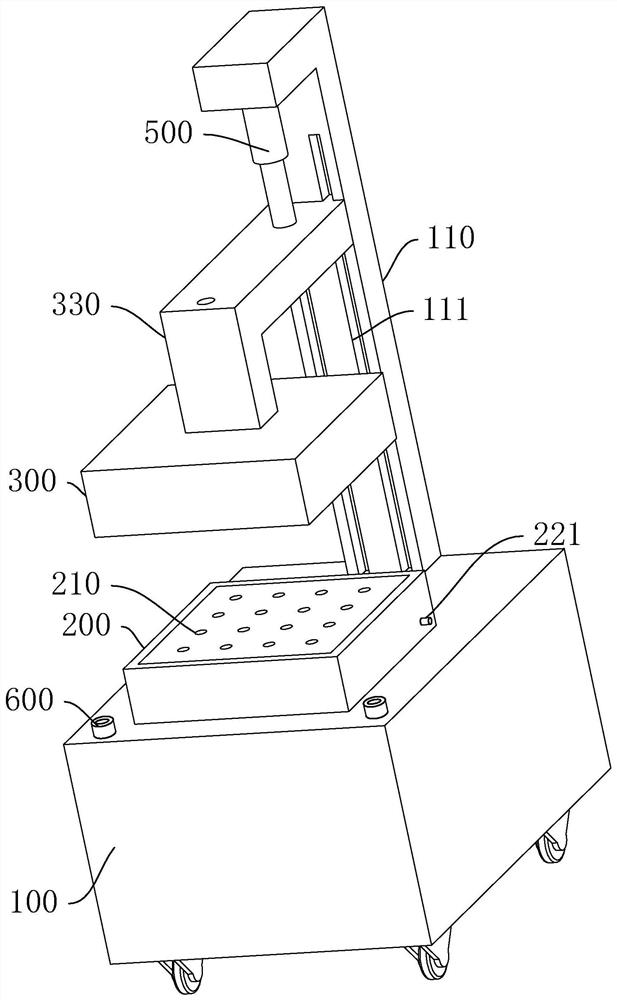

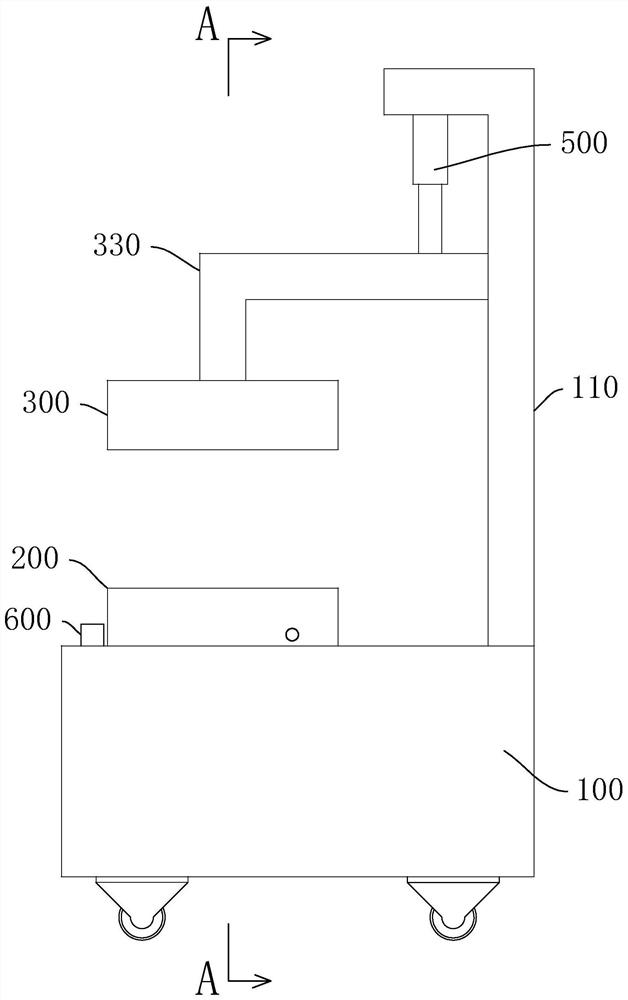

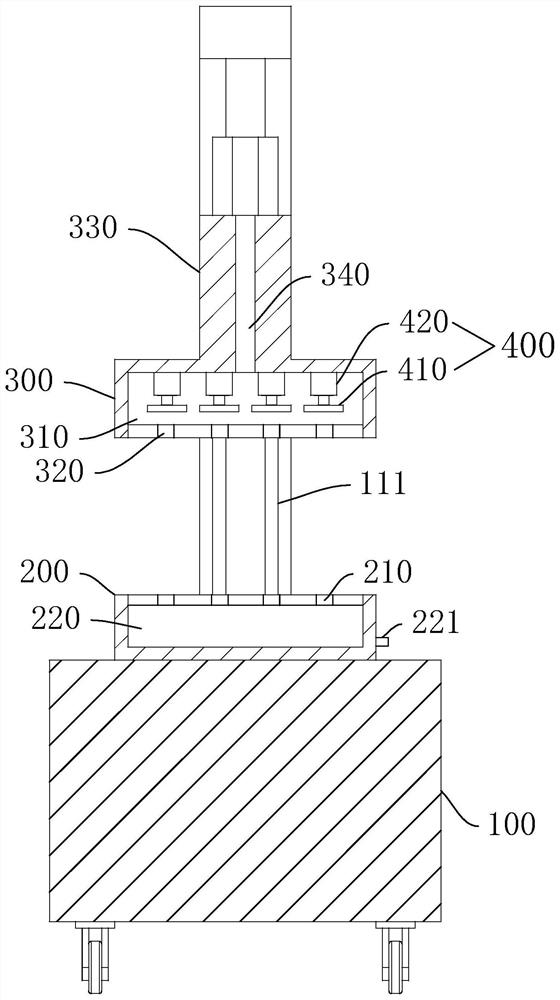

[0032] The garment processing and finishing device of the present embodiment includes a workbench 100, a lower ironing die 200, an upper ironing die 300, a plurality of air outlet blocking mechanisms 400 and an ironing lifting mechanism, and the lower ironing die 200 is installed on the bottom of the workbench 100. On the upper surface, a plurality of exhaust holes 210 are evenly distributed on the upper surface of the lower ironing mold 200, the upper ironing mold 300 is arranged directly above the lower ironing mold 200, and the workbench 100 is connected with a vertical The set support frame 110, the ironing lifting mechanism in this embodiment includes a lifting drive cylinder 500, the lifting drive cylinder 500 is fixed on the support frame 110, and the telescopic end of the lifting drive cylinder 500 is fixed to the ironing upper mold 300 connection, so that the ironing upper mold 300 and the ironing lower mold 200 can be connected as a whole through the workbench 100, an...

Embodiment 2

[0041] Embodiment 2: The garment processing and ironing device also includes a controller and two switch assemblies 600, the two switch assemblies 600 are installed on the workbench 100 at intervals, and the controller is connected in series with the two switch assemblies 600 , the controller is connected to the ironing lifting mechanism, and the controller is configured to control the ironing lifting mechanism to drive the ironing upper mold 300 to move after receiving the signals transmitted by the two switch assemblies 600. When the ironing upper mold 300 needs to be moved, it is necessary to press the two switch assemblies 600 to enable the controller to control the ironing lifting mechanism to drive the ironing upper mold 300 to move. At this time, the worker presses the two switch assemblies 600 with both hands. , so that when the ironing upper mold 300 is pressed or opened, the worker's hands remain pressed on the two switch assemblies 600, thereby preventing the worker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com