Prefabricated beam anti-tilting support

A prefabricated beam and anti-tilt technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of poor stability and length of prefabricated beams, achieve good stability, ensure stability, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

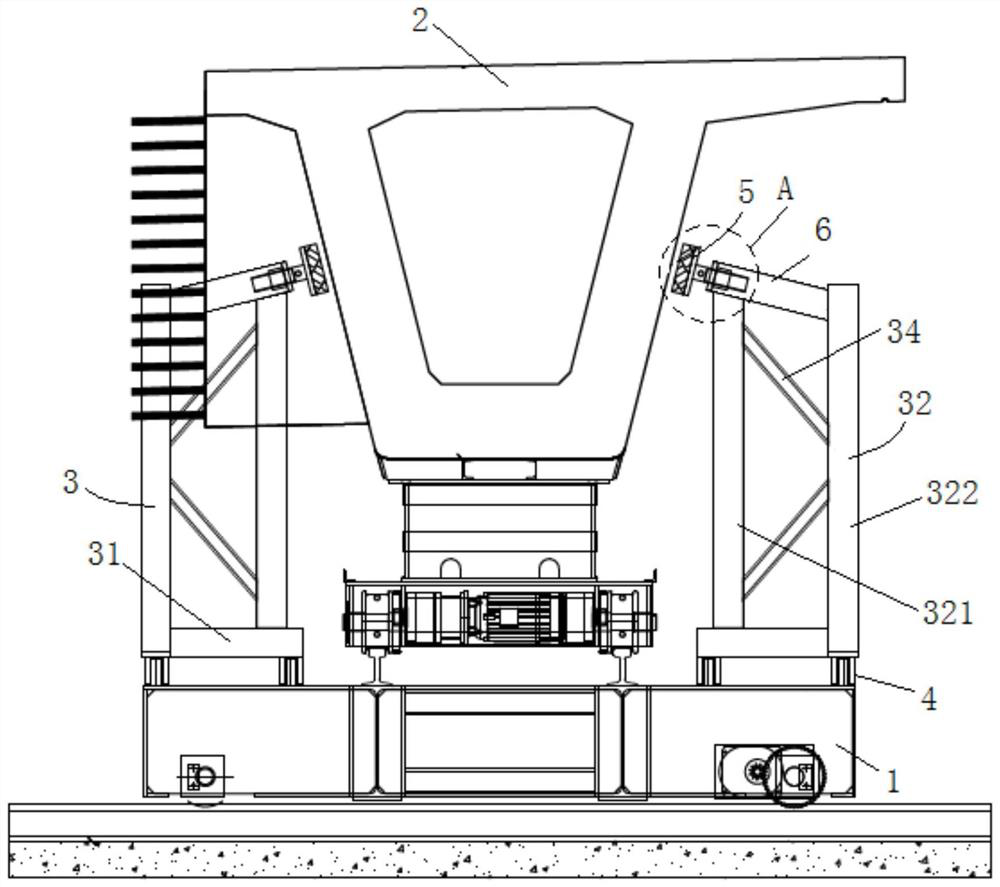

[0035] In one embodiment provided by this application, such as figure 1 As shown, the uprights 32 include a first upright 321 close to the prefabricated beam 2 and a second upright 322 far away from the prefabricated beam 2 , and two second braces 34 are arranged between the first upright 321 and the second upright 322 . Optionally, the two second diagonal braces 34 are in a figure-eight shape, the ends of the two second diagonal braces 34 arranged on the first column 321 are far apart, and the ends of the two second diagonal braces 34 arranged on the second column 322 are relatively far apart. close. The splayed bracing makes the first column 321 and the second column 322 have a containment and support structure, so that the first column 321 and the second column 322 can support each other.

Embodiment 2

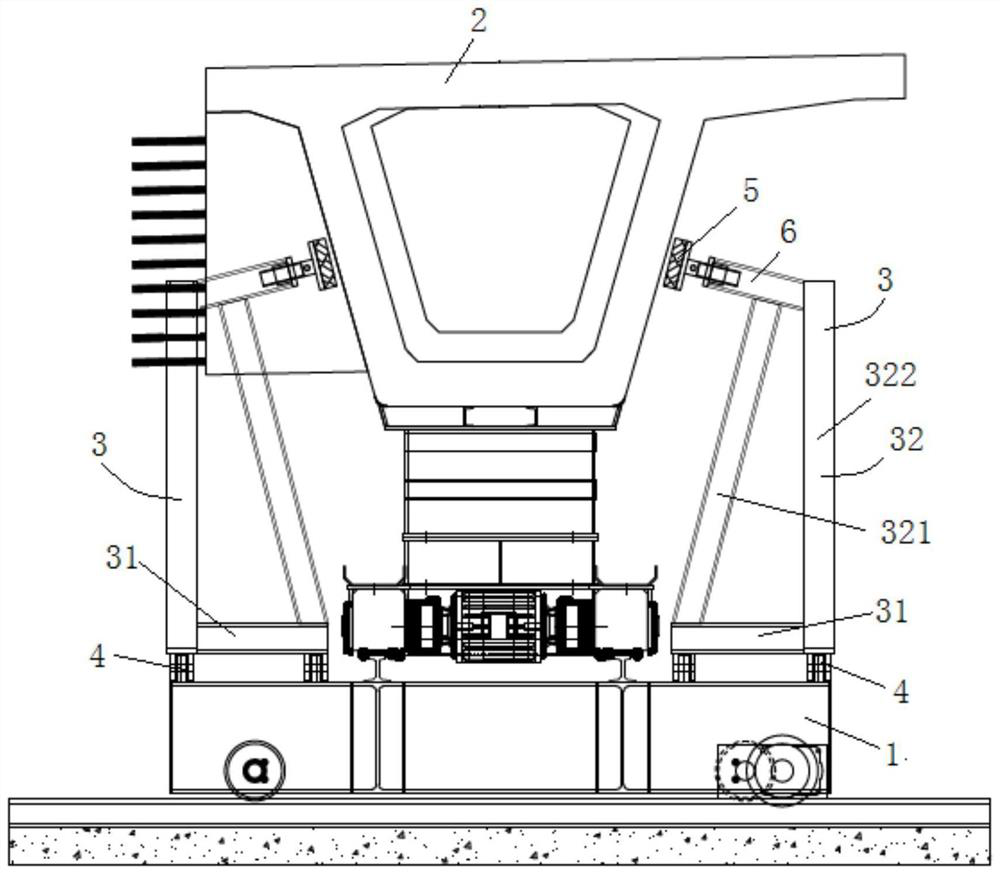

[0037] In one embodiment provided by this application, such as figure 2 As shown, the column 32 includes a first column 321 close to the prefabricated beam 2 and a second column 322 away from the prefabricated beam. The top of the first column 321 is inclined to the second column, and the second column 322 is perpendicular to the beam. The first column 321 is arranged obliquely so that the first column 321 can support the first brace 6 eccentrically. When the support frame 3 supports the prefabricated beam 2 and is subjected to the pressure exerted by the prefabricated beam 2 on the support frame, the beam 31 is bolted on the basis of the connecting seat , the first column can restrain the first brace 6 from exerting too much force on the second column 322, thereby ensuring the stability of the entire support frame structure.

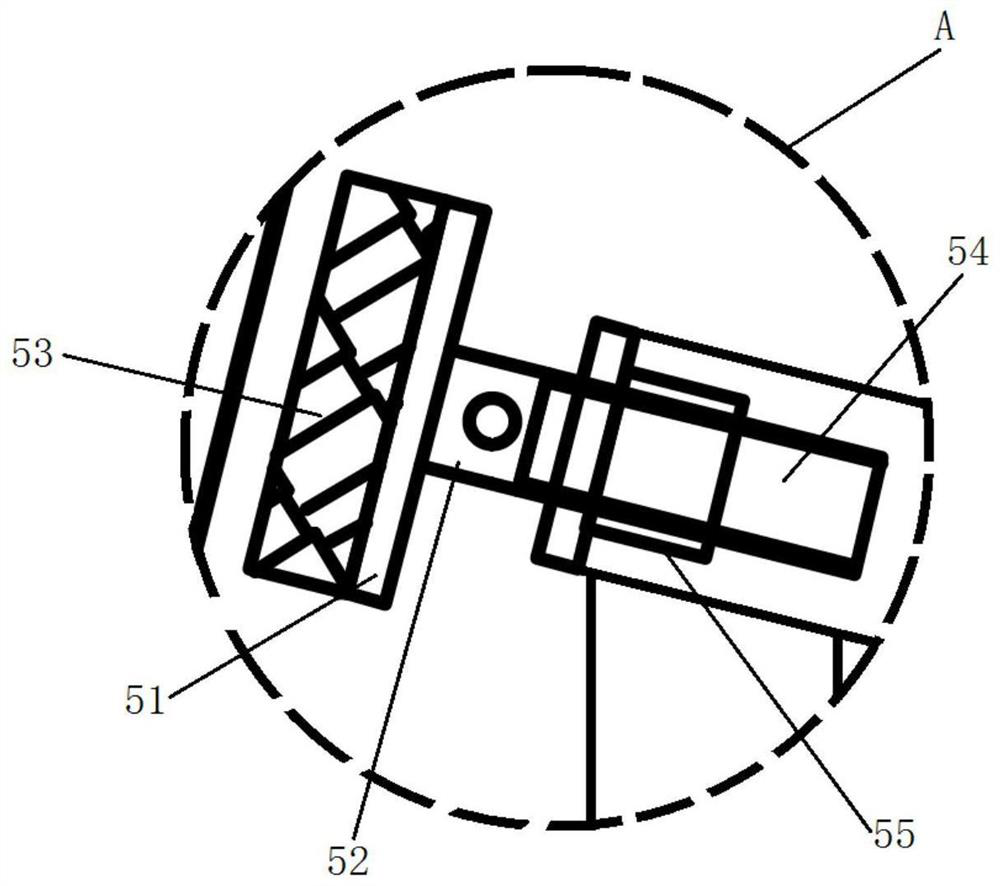

[0038] In the examples provided by this application, such as image 3 As shown, the tightening mechanism 5 includes a tightening plate 51 that tighte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com