Throttle body for small gasoline engine electromechanical injection system

A small gasoline engine and throttle body technology, which is applied in engine cooling, mechanical equipment, air cooling, etc., can solve the problems of heat dissipation of parts, easy heating of parts, and inconvenient air circulation, etc., so as to improve service life and fast ventilation Heat dissipation and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

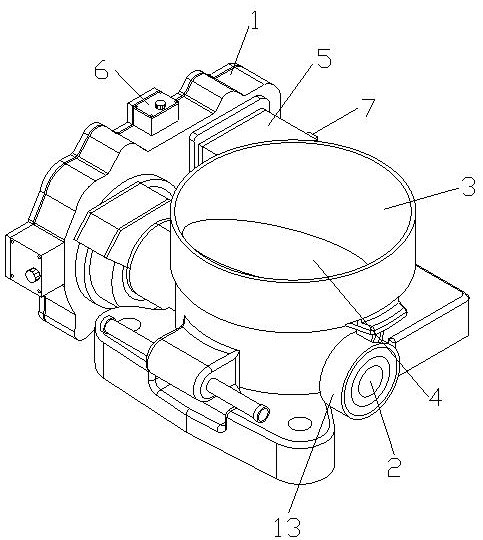

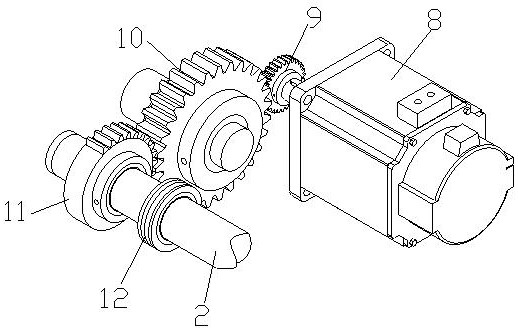

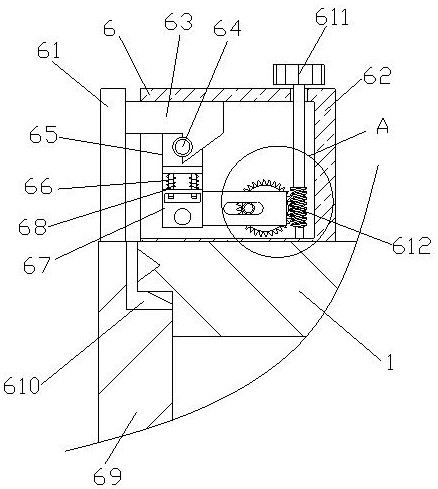

[0031] see figure 1 with figure 2 , the present invention provides a throttle body for a small gasoline engine electric injection system through improvement, including a gear housing 1 and a transmission shaft 2, the gear housing 1 is installed in the middle of the left end face of the throttle body 3, and the right end face of the gear housing 1 The end is connected with the motor box 5, the transmission shaft 2 vertically runs through the middle part of the right end surface of the throttle body 3 and the rear end of the right end surface of the gear housing 1, the outer middle part of the transmission shaft 2 is fastened to the inner middle part of the throttle plate 4, and the right end surface of the throttle body 3 A position sensor 13 is installed, and a motor 8 is arranged at the right end of the inner bottom end surface of the motor box 5. The output shaft on the left side of the motor 8 passes through the front end of the right end surface of the gear housing 1 and ...

Embodiment 2

[0038] The present invention provides a throttle body for a small gasoline engine electric injection system through improvement. The front end of the right end face of the gear housing 1 is hollowed out, so that the output shaft on the left side of the motor 8 enters the gear housing 1 to connect with the driving gear 9 , the size of the outer side of the throttle plate 4 corresponds to the inner side of the throttle body 3, which is convenient for the throttle body 4 to completely seal the inside of the throttle body 3 after rotation.

[0039] The present invention provides a throttle body for a small gasoline engine electric injection system through improvement, and its working principle is as follows;

[0040] First, at first this device is fixedly installed on the designated position on the gasoline engine as a whole, and the two ends of the throttle body 3 are respectively connected to the proper position of the designated parts on the gasoline engine, and the motor 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com