Rotary compressor and method

A technology of rotary compressor and pressure control chamber, which is applied in the direction of rotary piston machinery, rotary piston pump, rotary piston type/swing piston type pump components, etc., which can solve the problems of changing and unable to realize the capacity of air conditioner compressors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

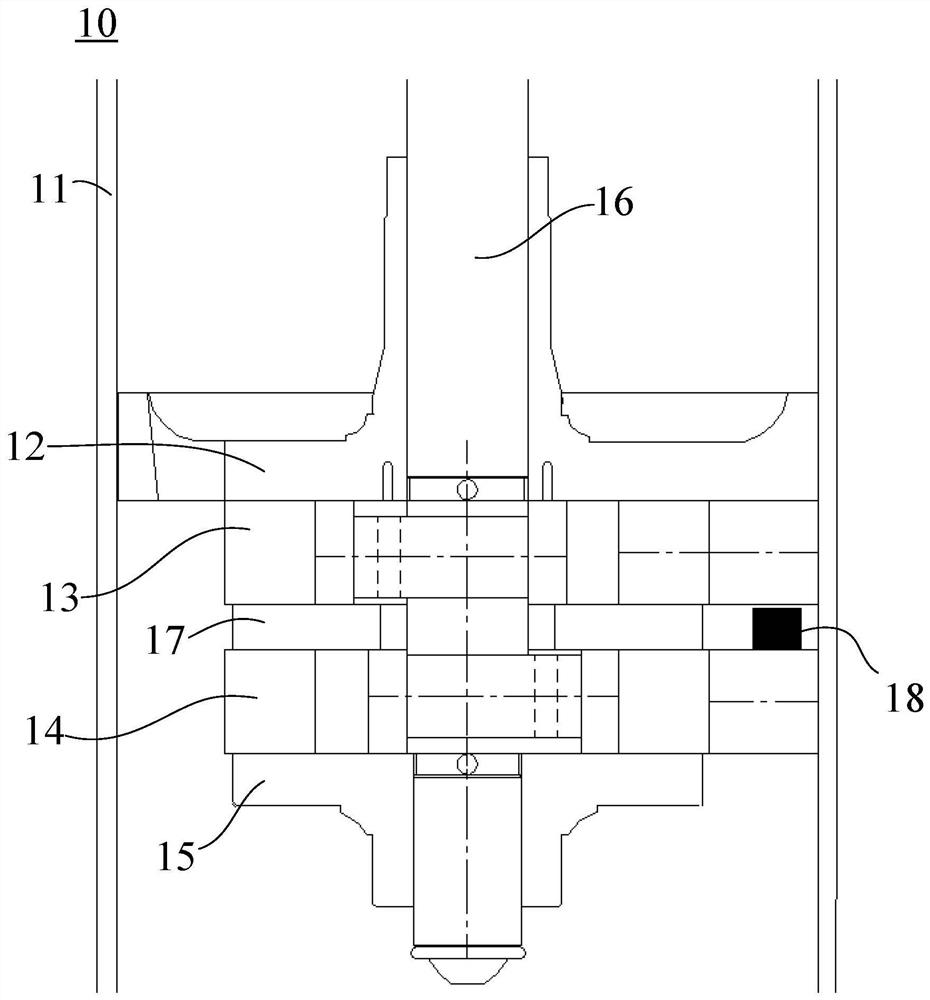

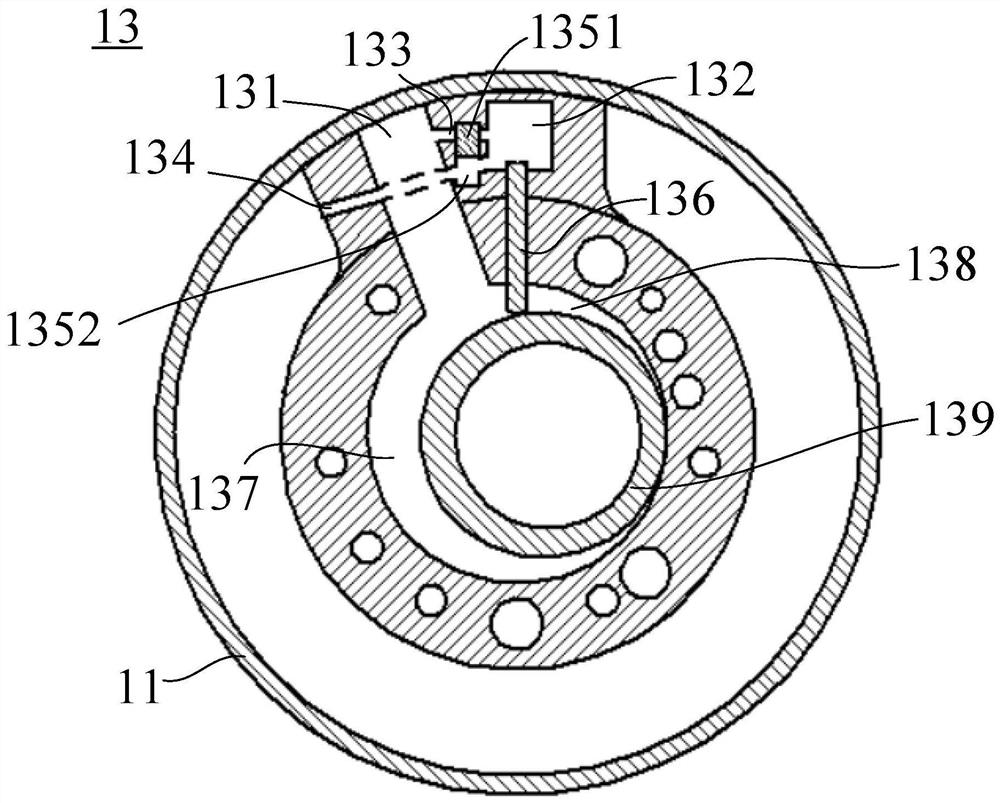

[0073] figure 2 It is a structural schematic diagram of a rotary compressor 10 . figure 2 The compressor 10 shown in the figure includes a casing 11, and two cylinders are arranged in the casing 11, that is, a first cylinder 13 and a second cylinder 14, the first suction cylinder is an upper cylinder, and the second cylinder 14 is a lower cylinder, some In an embodiment, the first cylinder 13 may be a lower cylinder, and the second cylinder 14 may be an upper cylinder. The first cylinder 13 and the second cylinder 14 are separated by an intermediate plate 17 . The first cylinder 13 is provided with a first rotary piston 139 , and the second cylinder 14 is provided with a second rotary piston. The two ends of the first cylinder 13 are the upper cylinder head 12 and the middle plate 17, and the two ends of the second cylinder 14 are the middle plate 17 and the lower cylinder head 15 respectively. The housing 11 is provided with a crankshaft 16. The crankshaft 16 has a long ...

Embodiment 2

[0079] Figure 5 It is a schematic structural diagram of the first cylinder 13 in Embodiment 2. Figure 6 yes Figure 5 Schematic diagram of the structure of the slider 1351 in the second position. refer to Figure 5 and Figure 6 , the difference between this embodiment and Embodiment 1 is that there is a connecting air channel 1353 inside the slider 1351, when the slider 1351 is in the first position, the second control air channel 134 is connected to the control chamber through the connecting air channel 1353 132 conducts, and when the slider 1351 is in the second position, the first control air channel 133 communicates with the control chamber 132 through the connecting air channel 1353 . The first position of the slider 1351 is the lower end of the chute 1352 , and the second position of the slider 1351 is the upper end of the chute 1352 .

[0080] Figure 5 The slider 1351 shown in is in the first position. At this time, the slider 1351 blocks the first control air...

Embodiment 3

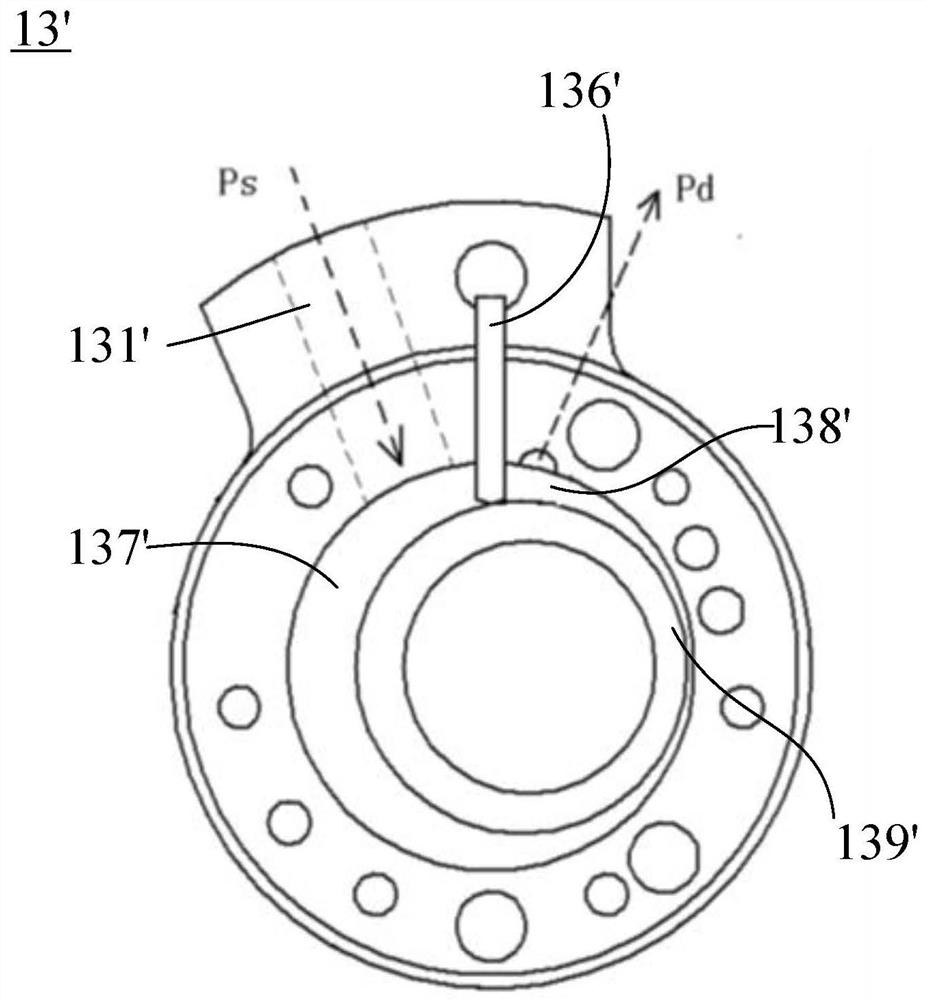

[0083] Figure 7 It is a schematic structural diagram of the first cylinder 13 in Embodiment 3. refer to Figure 7 The difference between this embodiment and Embodiment 2 is that: one side of the slot of the first vane 136 is provided with a stop groove 1354, and when the slider 1351 is in the second position, the stop groove 1354 and the inside of the casing 11 The space communicates to lock the first blade 136 . When the slider 1351 is at the first position, the stop groove 1354 communicates with the first suction channel 131 . When the slider 1351 slides to the second position (the upper end of the sliding slot 1352), the stop groove 1354 is filled with high-pressure gas, and the high-pressure gas presses the first vane 136, so that the first vane 136 is fixed on the first vane 136 in the slot.

[0084] In some embodiments, one side of the first vane 136 is provided with a pneumatic locking cylinder. When the slider 1351 is in the second position, the free end of the pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com