Auxiliary device capable of adjusting jacking pipe stress and construction method

An auxiliary device, adjustable technology, applied in the direction of pipeline laying and maintenance, pipe/pipe joints/fittings, mechanical equipment, etc., can solve problems such as cracks in pipe jacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

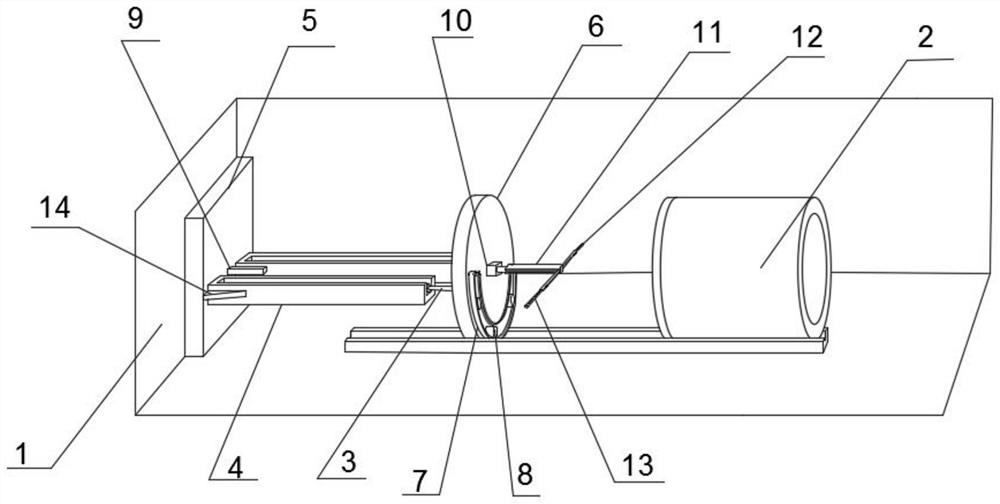

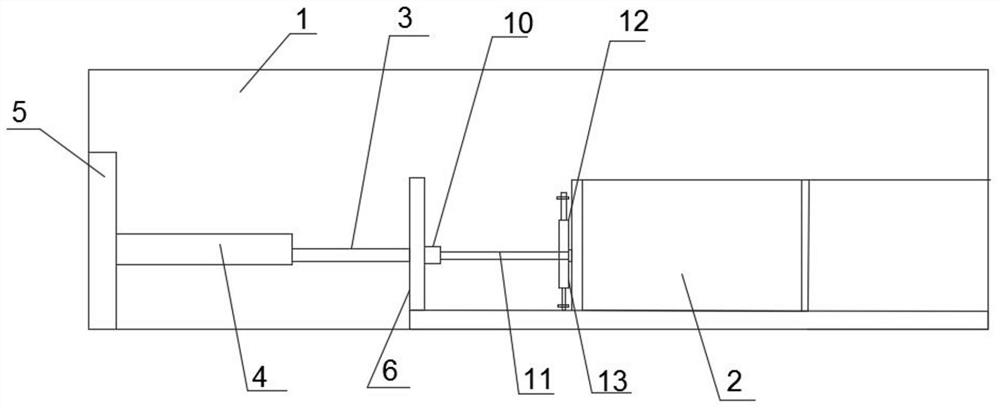

[0042]Such asFigure 1 to Figure 5Shown: an auxiliary device that can adjust the force of a jacking pipe, including a jacking pit 1, a jacking pipe 2, and a jack 3, and also includes a limit rod 4, a first connecting plate 5, a second connecting plate 6 and a fitting piece , The limit rod 4 is provided with a groove, the shell body of the jack 3 is installed in the groove, one side of the first connecting plate 5 is bolted to the wall of the jacking pit 1, and the other side of the first connecting plate 5 is connected with Limit rod 4 welding;

[0043]The second connecting plate 6 is located on the end of the limiting rod 4 away from the first connecting plate 5. The second connecting plate 6 is welded to the plunger of the jack 3, and the side of the jack 3 opposite to the plunger is welded to the first connecting plate 5. ;

[0044]The fitting includes an arc-shaped crawler frame 7 and a push cylinder 8. The arc-shaped crawler frame 7 is located on the side of the second connecting plat...

Embodiment 2

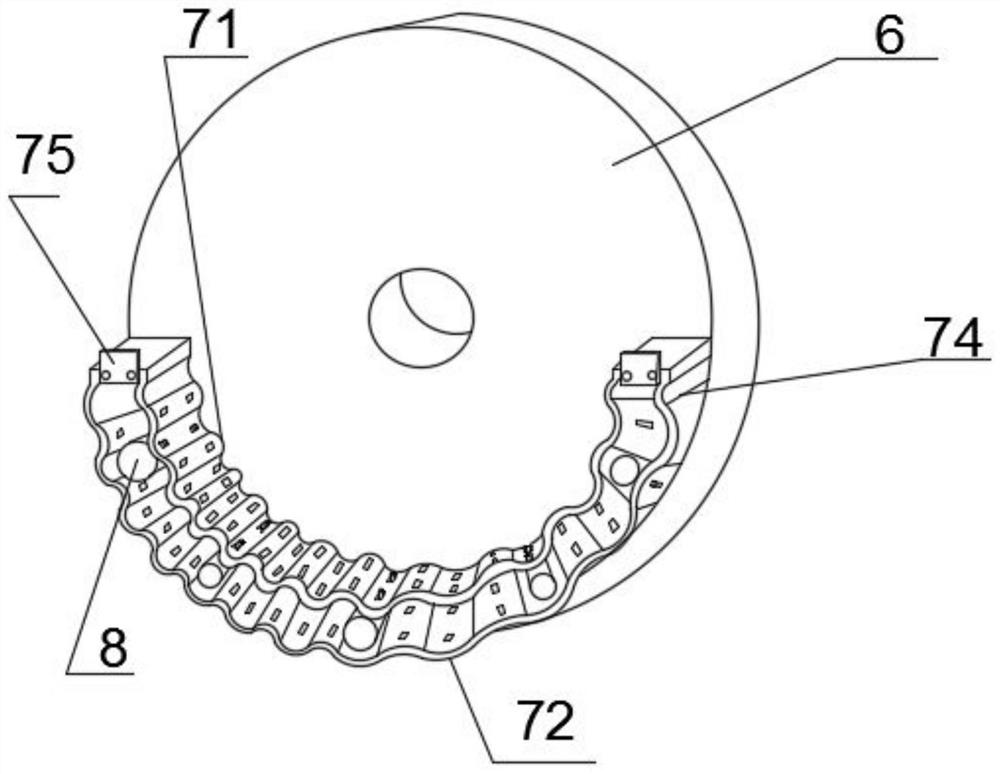

[0061]Such asFigure 6 As shown, the installation method of the arc-shaped upper piece 71 and the arc-shaped lower piece 72 is changed to the groove and convex groove at the connection, and a stop is provided at the end of the groove away from the second connecting plate 6. The arc-shaped upper piece One side of the connection of 71 is a groove, and the other side of the connection of the arc-shaped upper piece 71 is a convex groove. Similarly, the two sides of the connection of the arc-shaped lower piece 72 are respectively provided with convex grooves and grooves, convex grooves and concave grooves. Groove insertion, the arc-shaped upper piece 71 and the arc-shaped lower piece 73 become a combined installation, and the stop is suitable for blocking the convex groove from punching out of the groove after being forced by the top tube 2. The arc-shaped upper piece 71 and the arc-shaped lower piece The piece 72 is glued to the second connecting plate 6 after the insertion is completed;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com