A kind of steel bar end burr grinding mechanism and using method

A technology of grinding mechanism and steel bars, which is applied to the parts of grinding machine tools, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve problems such as large errors, achieve short grinding time, constant grinding effect, and uniform propulsion force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

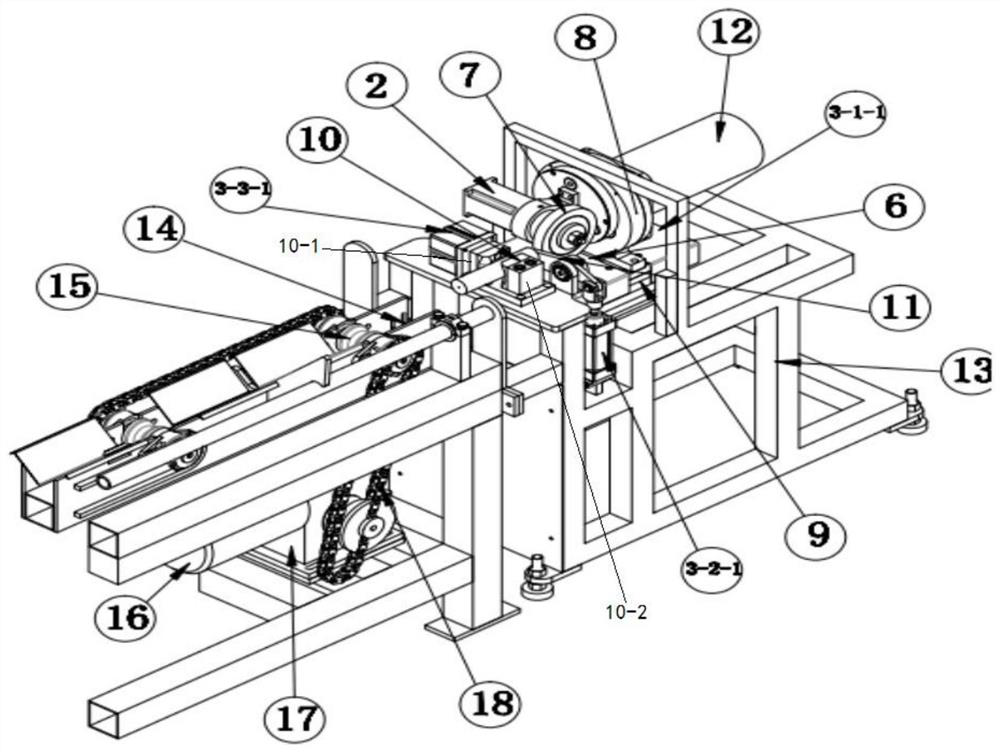

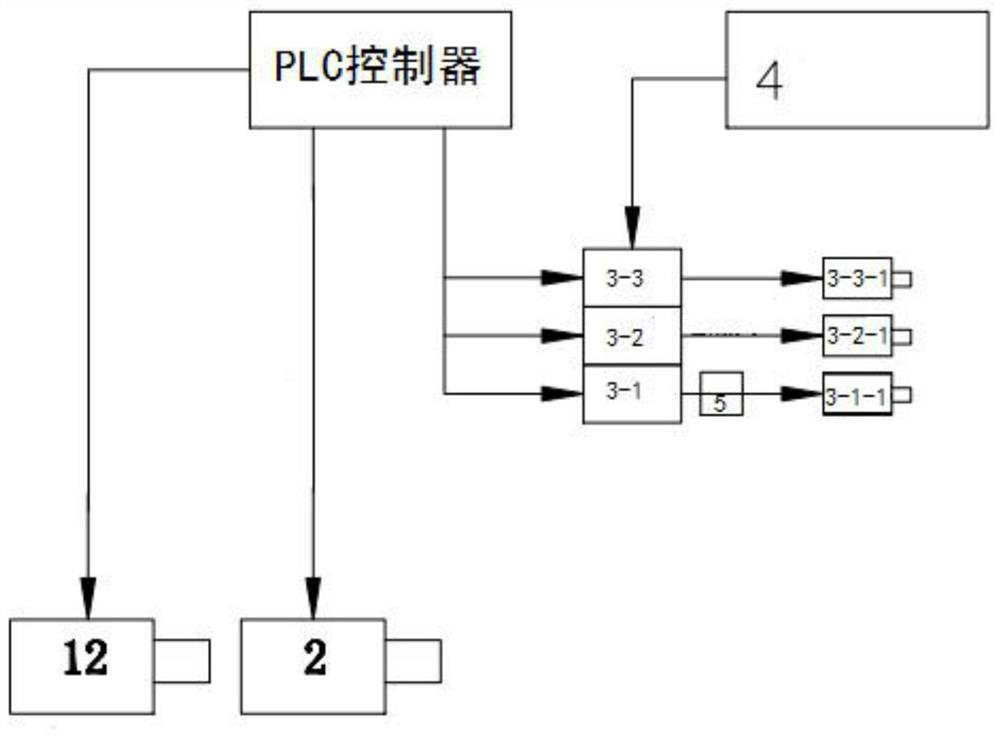

[0025] Such as figure 1 with figure 2 As shown, a reinforcing mechanism includes a grinding mechanism and a steel transport mechanism including an eccentric rotating mechanism 8 and a rack 13, and an eccentric rotating mechanism 8 is connected to a eccentric rotary motor having a driving eccentric rotating mechanism 8. 12, the eccentric rotating mechanism 8 is connected to the second motor 2, the second motor 2 output shaft is connected to the grinding wheel 7, and the eccentric rotating mechanism 8 is connected to the rack 13, and the rack 13 is also connected to a PLC controller, a PLC controller. Connect to the second motor 2 electrical signal, the steel transport mechanism is connected to the front of the frame 13 for transporting the steel bar to the grinding wheel 7, wherein the reinforcing mechanism is also attached to the sensor 14, and the sensor 14 is connected to the PLC controller electrical signal. A clamping mechanism 10 is also connected to the rack 13 in front of t...

Embodiment 2

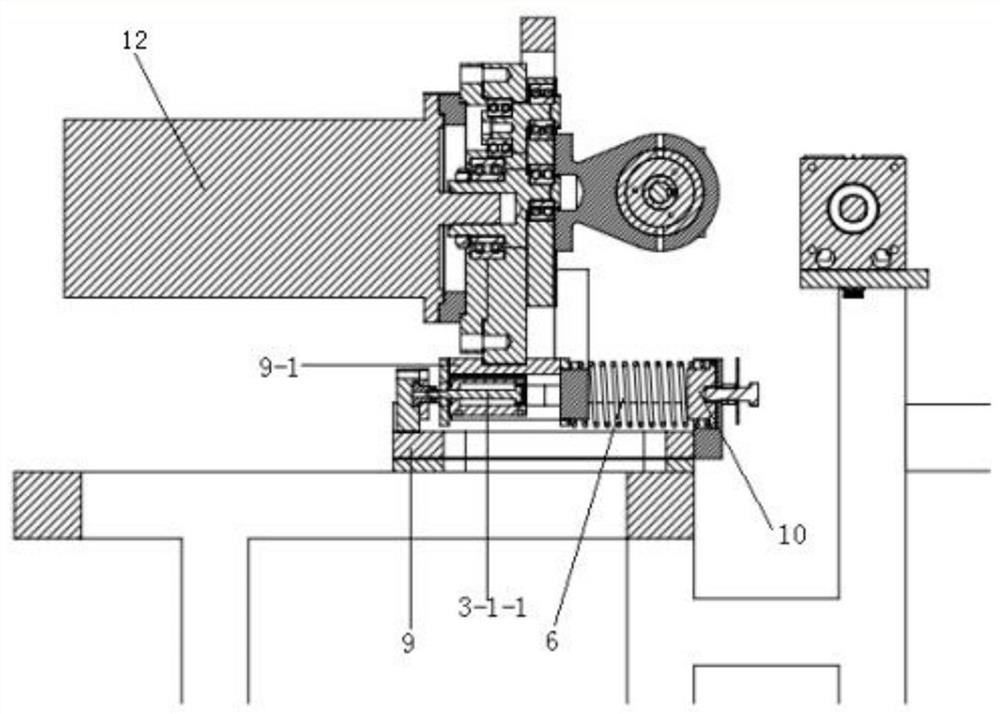

[0030] Such as figure 1 with figure 2 As shown, on the basis of the first embodiment, the eccentric rotating mechanism 8 is connected to the slider 9-1, and the frame 13 is connected to the frame 13, and the slider 9-1 is mounted in the first guide slide. On the rail 9, there is also a first cylinder 3-1-1 in the slider 9-1, and the first cylinder 3-1-1 rear end is connected to the baffle of the first guide slide 9, the first cylinder 3- 1-1 Connect the air compressor 4 through the pipe, the first solenoid valve 3-1 and the air pressure adjustment table 5, the first solenoid valve, and the first solenoid valve are connected to the conduit between the first cylinders 3-1-1 and the air compressor 4. 3-1 and Air Pressure Adjustment Table 5 are connected to the PLC controller electrical signal.

[0031] Such as image 3As shown, the eccentric rotating mechanism 8 is connected to the slider 9-1, and the first guide slide rail 9 is connected, and the first guide rail 9 is connected to th...

Embodiment 3

[0037] Such as figure 1 with figure 2 As shown, on the basis of Example 2, the clamping mechanism includes a first fixing block 10-1 and a second fixing block 10-2, and the first fixed block 10-1 is connected to the rack 13, and the second fixation is Block 10-2 is connected to the frame 13 by the second sliding guide, and the first fixed block 10-1 and the second fixed block 10-2 are left out, and the second fixed block 10-2 is away from the first fixed block. On one side of 10-1 is also connected with a third cylinder 3-3-1 for pushing the second fixing block 10-2 on the second sliding guide rail, the third cylinder 3-3-1 is connected to the rack 13, Moreover, the third cylinder 3-3-1 is connected to the pipeline 4, and the third cylinder 3-3-1 and the tube between the third cylinders 3-3-1 and the air compressor 4 are connected to the third solenoid valve 3-3, the third solenoid valve. 3-3 Connect to the PLC controller electrical signal.

[0038] The first fixing block 10-1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com