Method for testing bendability and extensibility of 3D printing cement-based material

A cement-based material, 3D printing technology, applied in the field of architectural 3D printing, can solve problems such as affecting the printing quality, prone to cracks in the printing corner, no detection method or standard, etc., to achieve the effect of quantitative performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

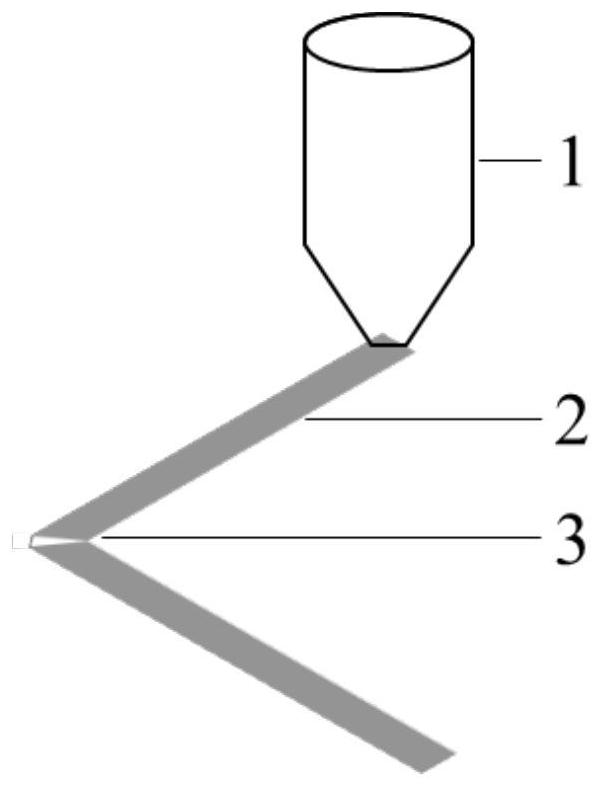

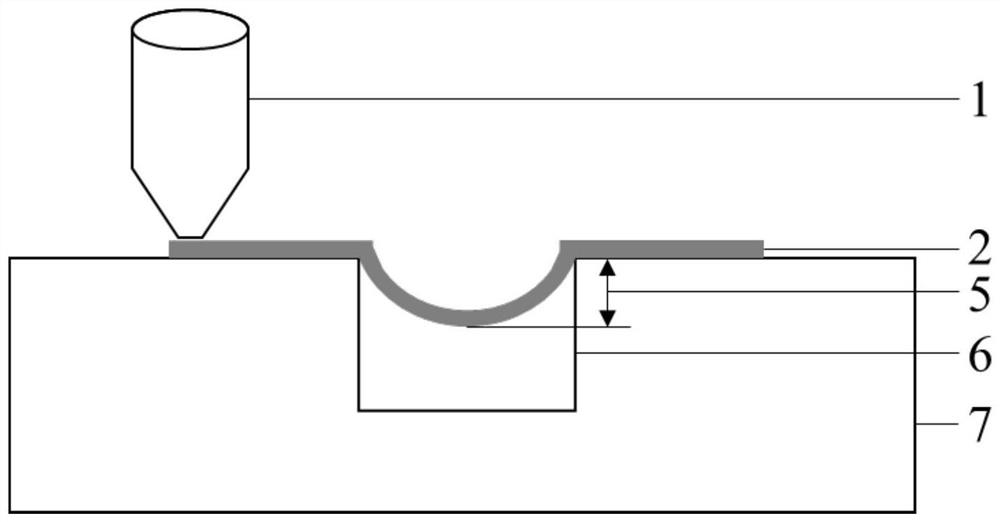

[0028] This embodiment provides a bending line test method of 3D printed cement-based material, and the bendability of cement-based material A is tested.

[0029] Add the cement-based material A to the extrusion device 1, the extrusion device 1 moves on the workbench, and extrude the cement-based material A according to the specified broken line path to form the cement-based material printing strip 2, and the angle of the broken line corner 3 is from 180° The gradient decreases successively from 10° to 10° each time, and it is found that when the angle of the broken line corner 3 of the cement-based material A decreases to 80°, cracks appear in the broken line corner 3, so it is concluded that the bendable angle of the cement-based material A is 90°.

Embodiment 2

[0031] This embodiment provides a bending line test method of 3D printed cement-based materials, and compares the bendability of cement-based material B, cement-based material C and cement-based material D.

[0032] Add the cement-based material B to the extrusion device 1, and the extrusion device 1 moves on the workbench to extrude the cement-based material B according to the specified broken line path to form the cement-based material printing strip 2, and the angle of the broken line corner 3 is 60° , after the printing is completed, the crack width of cement-based material B at corner 3 of the broken line is measured to be 1.1mm. The bending properties of cement-based material C and cement-based material D are tested in the same way, and it is measured that cement-based material C is at The width of the crack at the corner 3 of the broken line is 0.5 mm, but there is no crack at the corner 3 of the cement-based material D, so it is concluded that the bending properties of ...

Embodiment 3

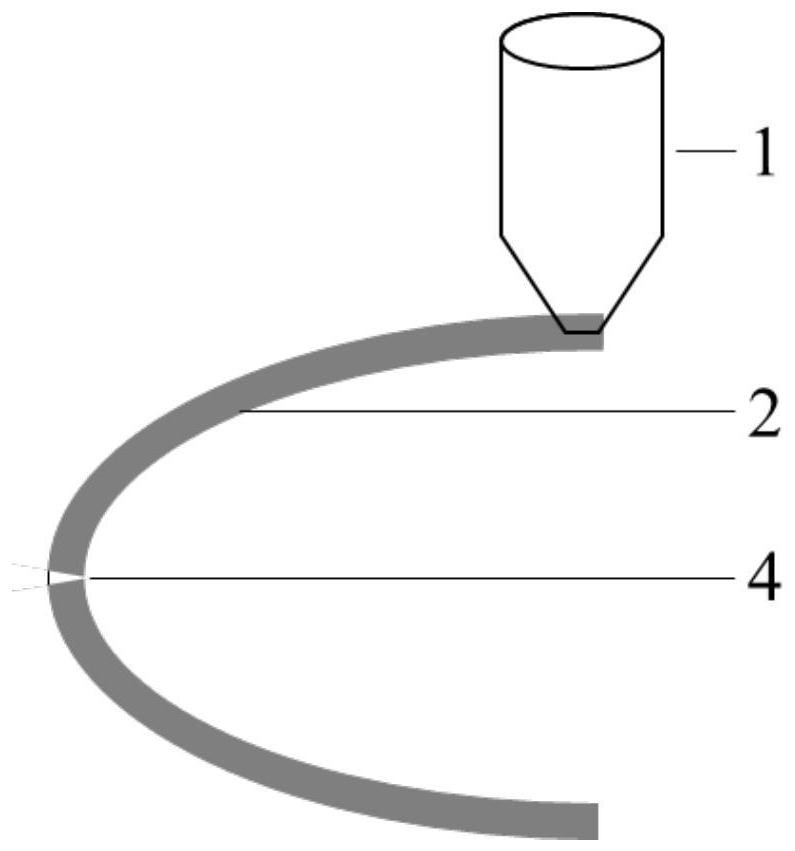

[0034] This embodiment provides a method for testing the bendability curve of a 3D printed cement-based material, and tests the bendability of the cement-based material E.

[0035] Add the cement-based material E to the extrusion device 1, and the extrusion device 1 moves on the workbench to extrude the cement-based material E according to the prescribed curve path to form the cement-based material printing strip 2, and the curvature of the curved corner 4 is from 1dm -1 to 5dm -1 Gradient increases in sequence, increasing 0.5dm each time -1 , it is found that the cement-based material E has a curvature from 3.5dm at the curve corner 4 -1 increased to 4dm -1 , cracks appear at the corner 4 of the curve, so it is concluded that the bendable curvature of the cement-based material E is 3.5dm -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com