Toothbrush conveying table

A conveying table and toothbrush technology, which is applied in the fields of toothbrush transfer, conveying, and material conveying, can solve the problems of low safety factor and low work efficiency, and achieve the effect of high degree of automation, high processing efficiency and good processing continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

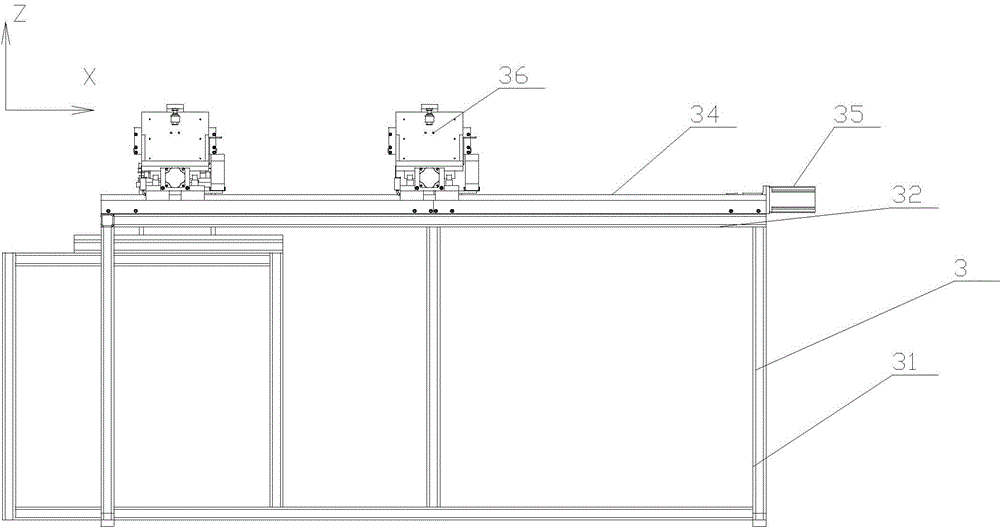

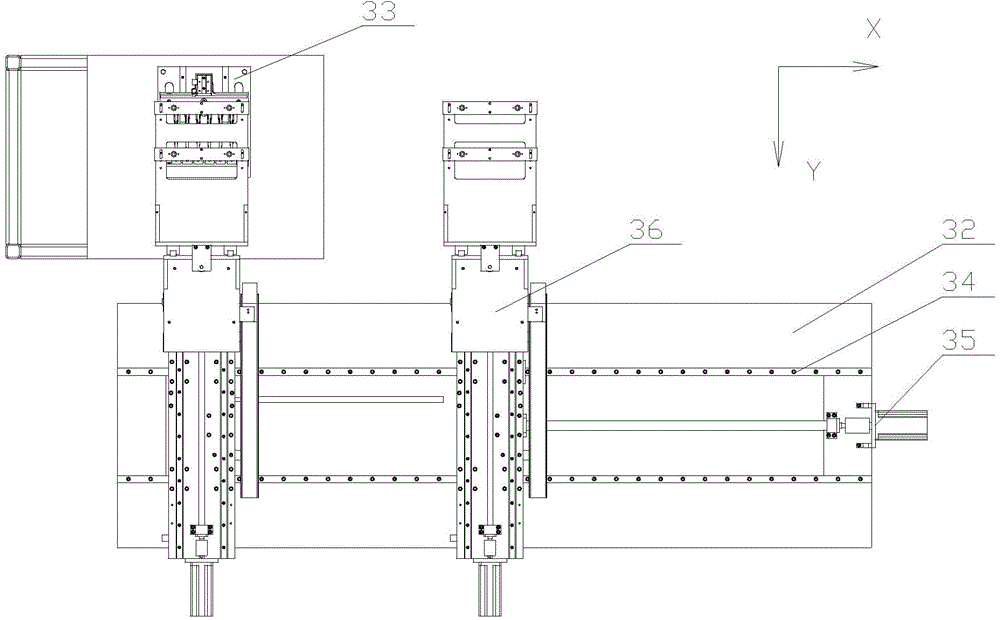

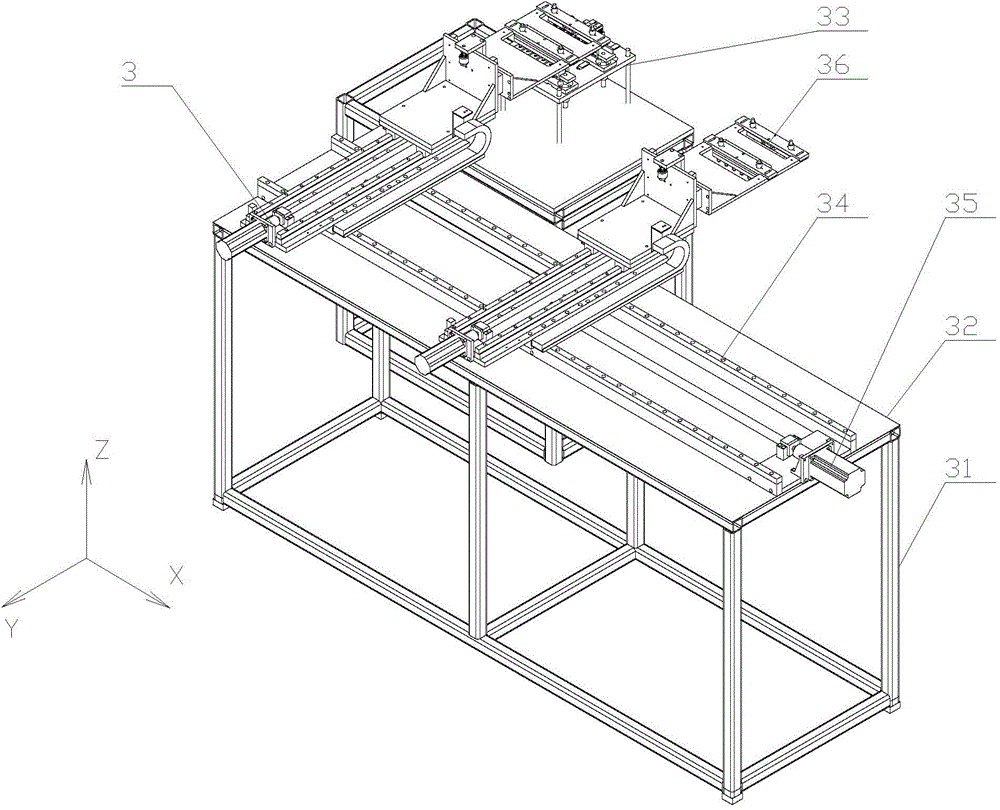

[0028] The present invention as Figure 1-7 As shown, it is arranged between the tufting machine 1 and the encapsulating machine 2, the tufting machine 1 has a discharge manipulator 10 for grabbing a single toothbrush, and the discharge manipulator 10 reciprocates on the ZX plane, so The encapsulation machine 2 has accommodating platforms for accommodating several toothbrushes, the top surface of the accommodating platforms is provided with a number of accommodating grooves arranged along the Y direction, and the accommodating platforms and the discharging manipulator 10 are located on the toothbrush delivery platform 3 the same side of

[0029] The 3 toothbrushes conveyed include a frame 31, a workbench 32, a turntable 33, a guide rail 34 arranged along the X direction, a linear drive device 35 and a pair of grasping mechanisms 36 arranged along the Y direction; the workbench 32 is fixed Connected to the top of the frame 31, the guide rail 34 is fixedly connected to the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com