A method for measuring the thermal conductivity of micro-powder samples under different temperature and pressure conditions in a vacuum environment

A technology of micro-powder and thermal conductivity, which is applied in the field of mineral rock materials, can solve the problems of the analysis of extraterrestrial analog samples and the inability to have them at the same time, and achieve the effects of simplifying operations, reducing the amount of samples, and using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

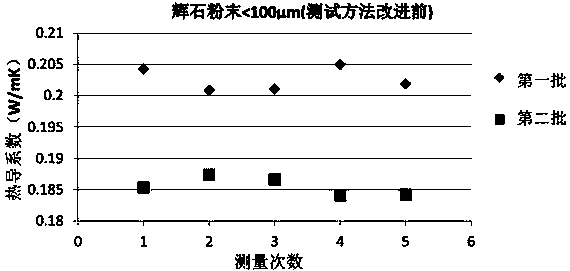

[0026] (1) Before the test method is improved, the sample is pre-treated. Prepare the pyroxene sample into a powder sample with a particle size not greater than 1mm according to your own needs to ensure that the sample is evenly mixed, and dry the sample before measurement.

[0027] (2) Before the test method is improved, the sample is installed. Choose 13.0cm 3 Put the pretreated pyroxene powder sample and test probe into the sample cell according to step (1), and fix the sample cell in the original sample chamber of the thermal conductivity meter.

[0028] (3) Before the test method is improved, the sample is tested. The thermal conductivity of the pyroxene powder sample was measured under normal temperature and pressure conditions. For the analysis of the data results, see Figure 5 . From Figure 5 It can be seen that the same sample is measured at different times, and its thermal conductivity is affected by the environment, resulting in large data fluctuations and la...

Embodiment 2

[0035] This embodiment 2 all carries out relevant test work under the condition after test method improvement.

[0036] (1) Sample pretreatment. Prepare the olivine sample into a powder sample with a particle size not greater than 1mm according to your own needs, ensure that the sample is mixed evenly, and dry the sample before measurement.

[0037] (2) Sample installation. Choose 4.7cm 3 Put the pretreated olivine powder sample and test probe into the sample cell according to step (1) and fix it, and finally put the sample cell into the vacuum chamber of the freeze dryer.

[0038] (3) Sample test. Vacuumize the vacuum chamber of the freeze dryer, and the pressure can be adjusted from 1Pa to 1.013×10 5 Pa, and can also adjust the temperature in the chamber at the same time, and the temperature can be adjusted from -190°C to 200°C. Select a pressure and temperature for each measurement, and monitor the temperature drift after the pressure and temperature reach the specifie...

Embodiment 3

[0042] This embodiment 3 all carries out relevant test work under the condition after test method improvement.

[0043] (1) Sample pretreatment. Prepare the simulated lunar soil sample into a powder sample with a particle size not greater than 1mm according to your own needs, ensure that the sample is mixed evenly, and dry the sample before measurement.

[0044] (2) Sample installation. Choose 1.0cm 3 Put the simulated lunar soil powder sample and the test probe that have been pretreated according to step (1) into the sample pool and fix them, and finally put the sample pool into the vacuum chamber of the freeze dryer.

[0045] (3) Sample test. Vacuumize the vacuum chamber of the freeze dryer, and the pressure can be adjusted from 1Pa to 1.013×10 5 Pa, and can also adjust the temperature in the chamber at the same time, and the temperature can be adjusted from -190°C to 200°C. Select a pressure and temperature for each measurement, and monitor the temperature drift after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com