A kind of liquid-liquid-liquid three-phase solvent system extracts and separates the method of natural product and its application

A technology of phase solvent and product, applied in the field of extraction and separation of natural products by liquid-liquid-liquid three-phase solvent system, can solve the problems of poor separation selectivity, restricted application, etc., and achieve mild separation conditions, simple operation and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] 1. Specific examples

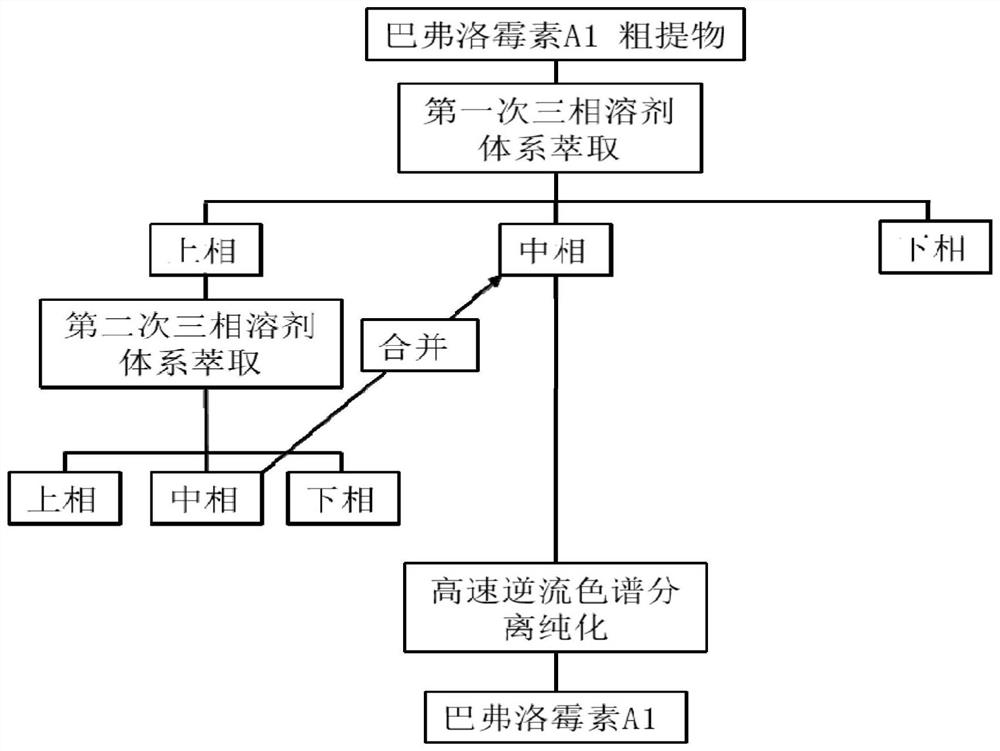

[0034] A method for extracting and separating natural products with a liquid-liquid-liquid three-phase solvent system, comprising the following steps:

[0035] (1) Select at least 4 solvents according to the target compound to be extracted;

[0036] (2) Select multiple solvents in step (1) according to different proportions, fully oscillate and mix to form a three-phase solvent system;

[0037] (3) Fully dissolve a certain amount of crude extract of the natural product to be extracted in the three-phase solvent system configured in step (2). After the phase separation of the three-phase solvent system is completed, take Quantitative samples were detected by HPLC to detect the content of the target compound;

[0038] (4) According to the content of the target compound in each phase in step (3), the volume of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com