An optical cable traction joint that reduces the core breakage rate of the optical cable

A technology of broken core rate and connector, applied in the direction of optical fiber/cable installation, etc., can solve problems such as broken core of optical cable, twisted optical cable, etc., achieve the effect of reducing broken core rate, reducing the probability of twisting, and enhancing the clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Attached to the following Figure 1-4 This application will be described in further detail.

[0033] The embodiment of the present application discloses an optical cable pulling connector for reducing the core breaking rate of the optical cable.

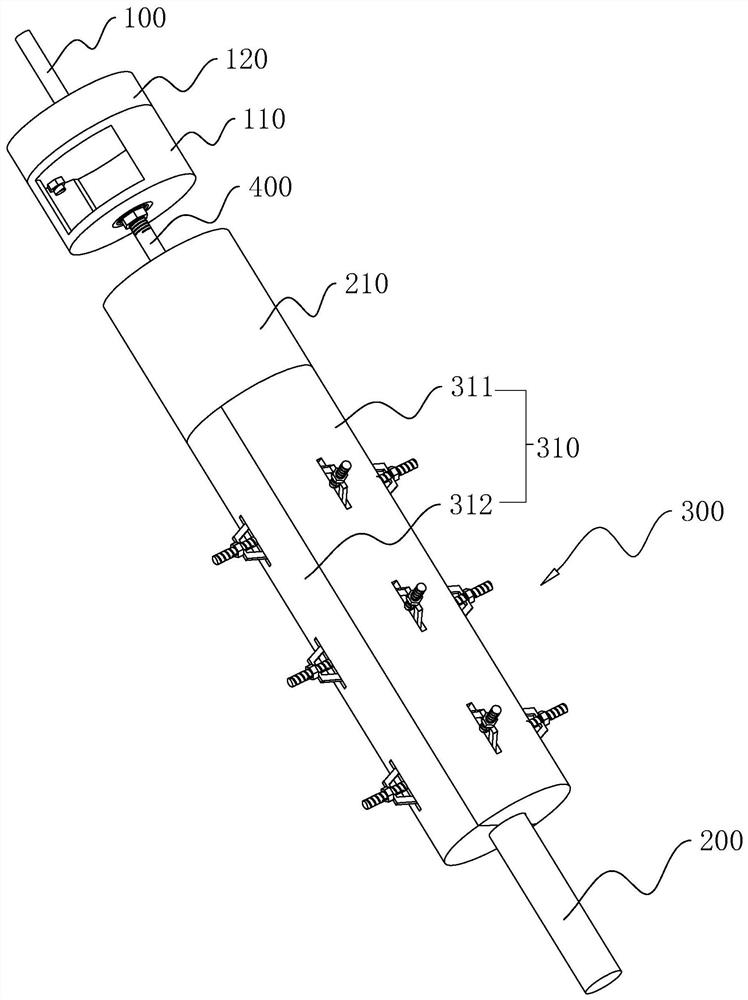

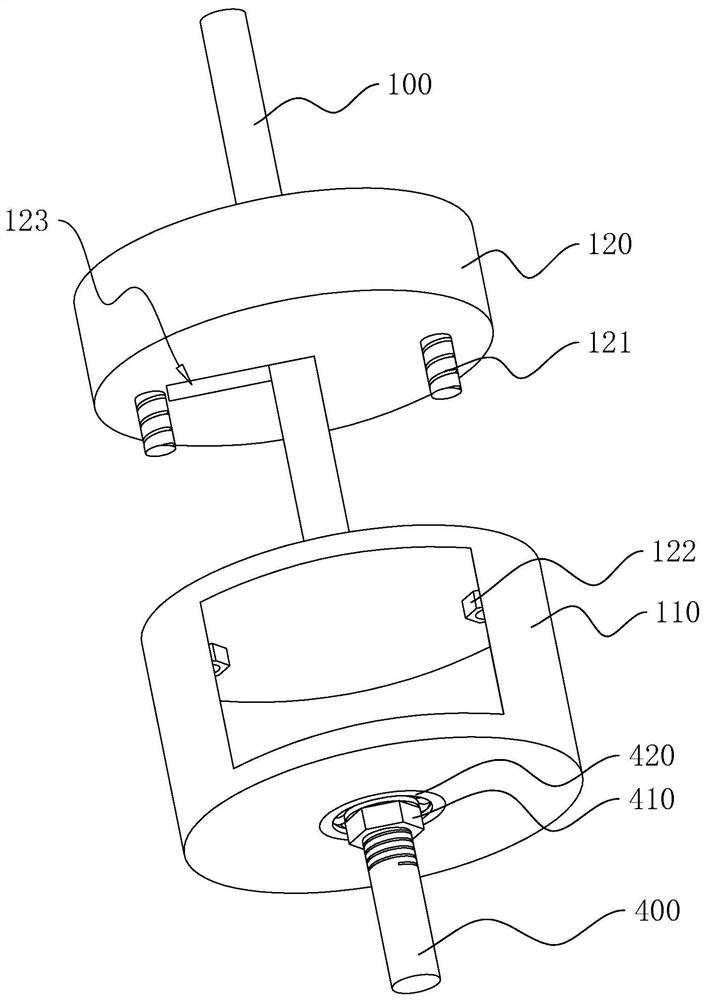

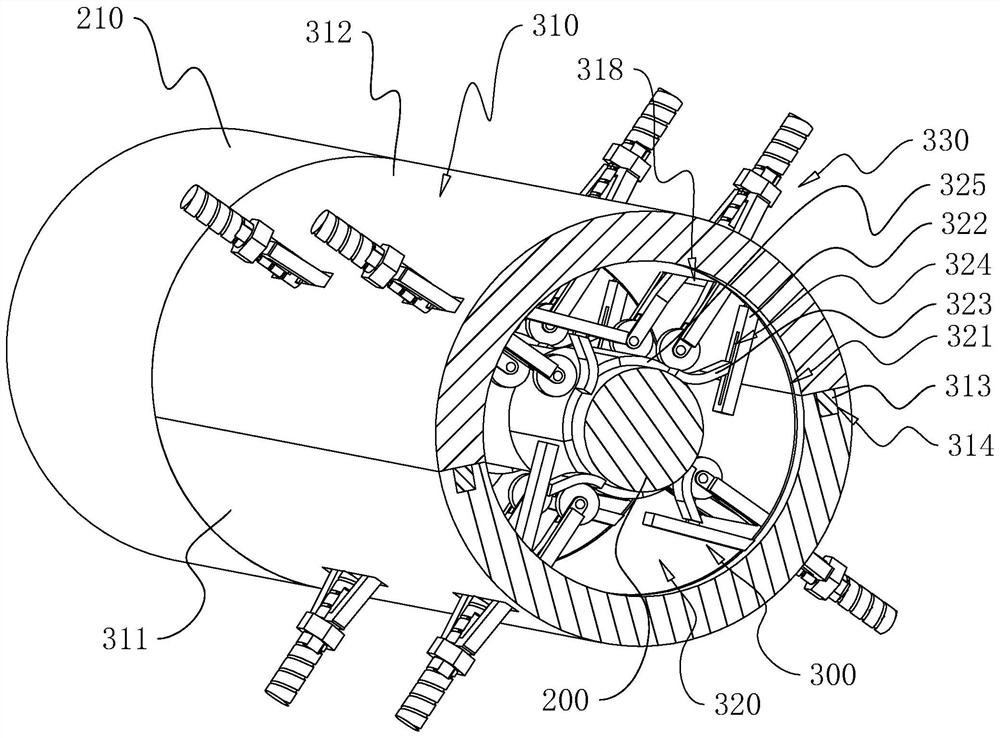

[0034] refer to figure 1 , the optical cable traction connector for reducing the breakage rate of the optical cable includes a first swivel 110, a second swivel 210 and a clamping assembly 300. The first swivel 110 is detachably connected to the traction rope 100, and the second swivel 210 is arranged on the On the optical cable 200 , a rotating rod 400 is rotated on the first rotating ring 110 , and one end of the rotating rod 400 away from the first rotating ring 110 is welded with the second rotating ring 210 . The clamping assembly 300 is disposed on the second rotating ring 210 and used for clamping the optical cable 200 . When laying the optical cable 200, after the connection between the traction rope 100 and the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com