Corrugator

A technology of corrugated board and web materials, which is applied in the directions of winding strips, mechanical processing/deformation, thin material processing, etc., can solve the problems of inflexible corrugated board system and not particularly user-friendly, and achieve the effect of simplifying planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

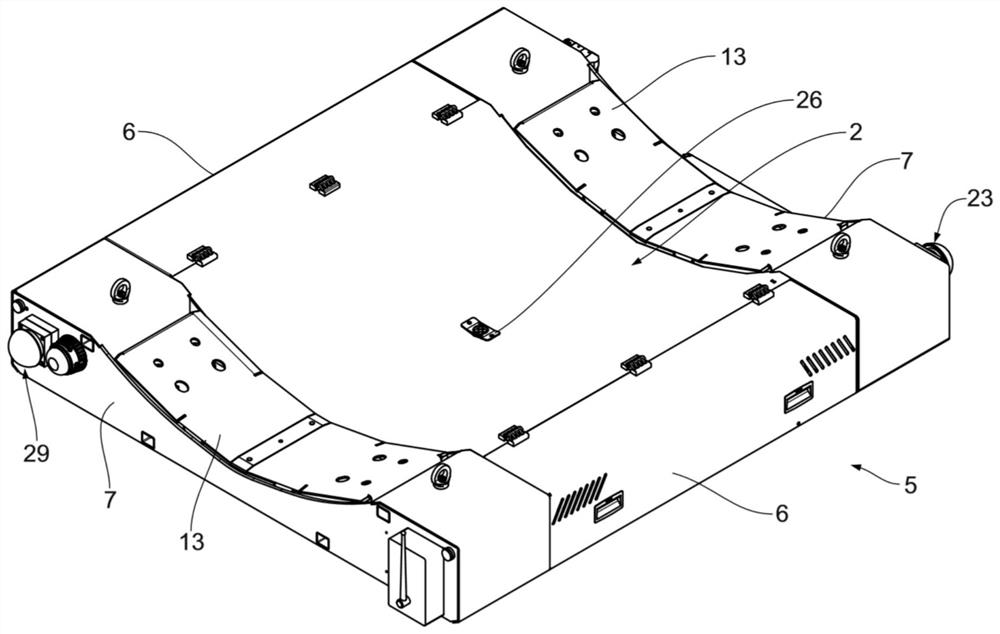

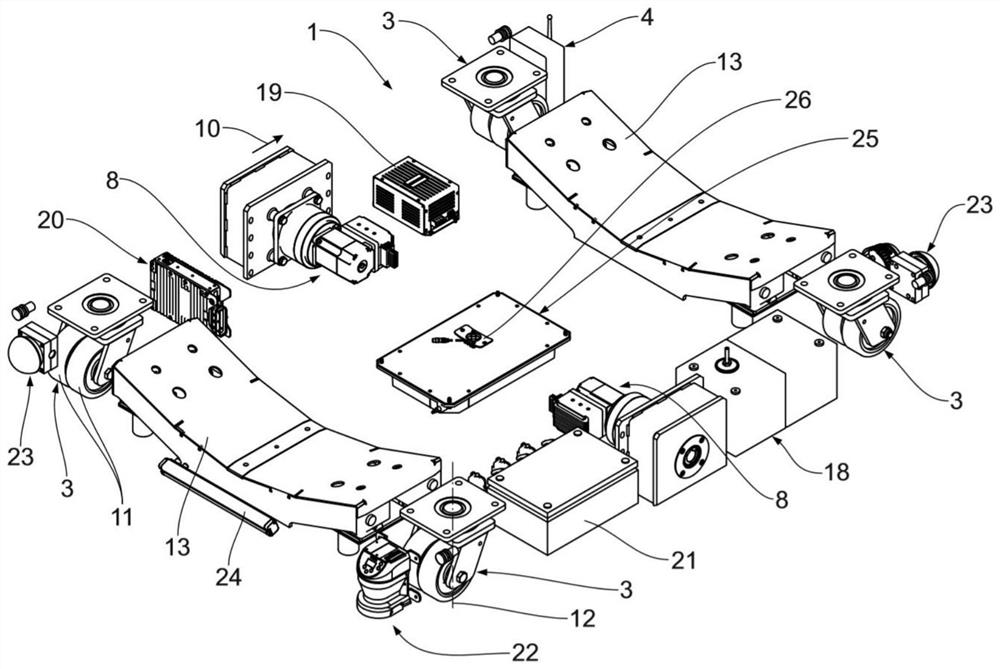

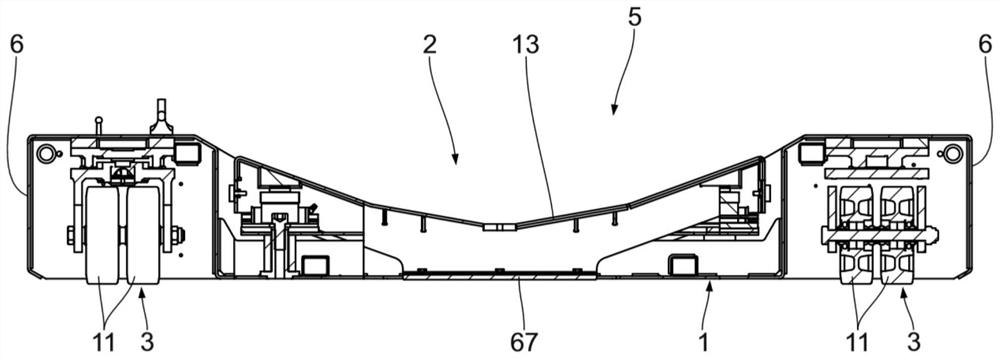

[0065] First refer to Figure 1 to Figure 5 , the configuration of the paper roll transport carriage 5 will be described. The paper roll transport carriage 5 has a rigid frame 1 which is in the shape of a frame or a chassis. The frame 1 carries a roll receiver 2 for a limited rolled-up web, and a plurality of wheel units 3 for moving a roll transport carriage 5 on an underlying surface, and communication means 4 .

[0066] The roll transport carriage 5 can be set to move depending on a signal or item of information received via the communication device 4 . Furthermore, its speed can thus be predefined, for example. Items of path or destination information can also be transferred to the roll transport carriage 5 accordingly. The paper roll transport carriage 5 can move straightly or bend.

[0067] The frame 1 has two longitudinal sides 6 and two transverse sides 7 . The longitudinal sides 6 extend parallel to each other and parallel to the roll receiver 2 . The lateral si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com