Cup with exhaust sealing ring assembled in cup cover

A technology for exhaust sealing and sealing rings, which is applied to the sealing of engines, drinking vessels, and engine components. Water works best and eliminates the effect of loose or detached lids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

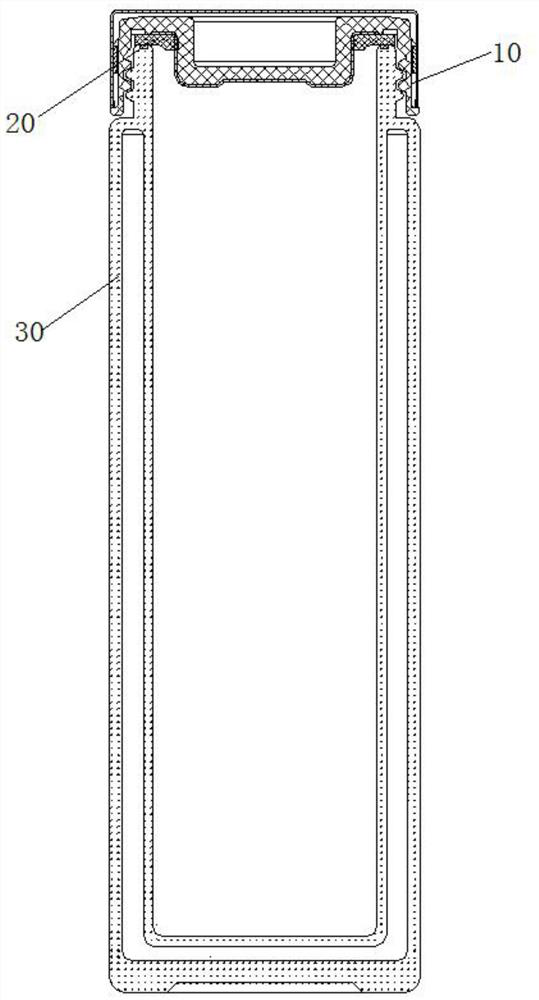

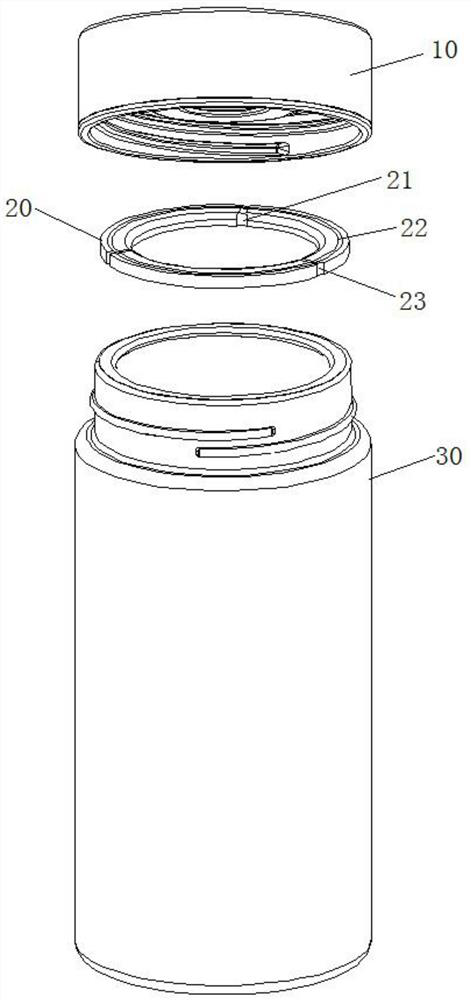

[0034] In some embodiments, such as figure 1 , figure 2 and image 3 As shown, a cup with an exhaust sealing ring installed in the cup cover is provided, including a cup cover 10, a sealing ring 20 and a cup body 30. The sealing ring 20 is assembled inside the cup cover 10 and is located between the cup body 30 and the cup cover 10. Between, and the connection between the cup cover 10 and the cup body 30 is screwed in.

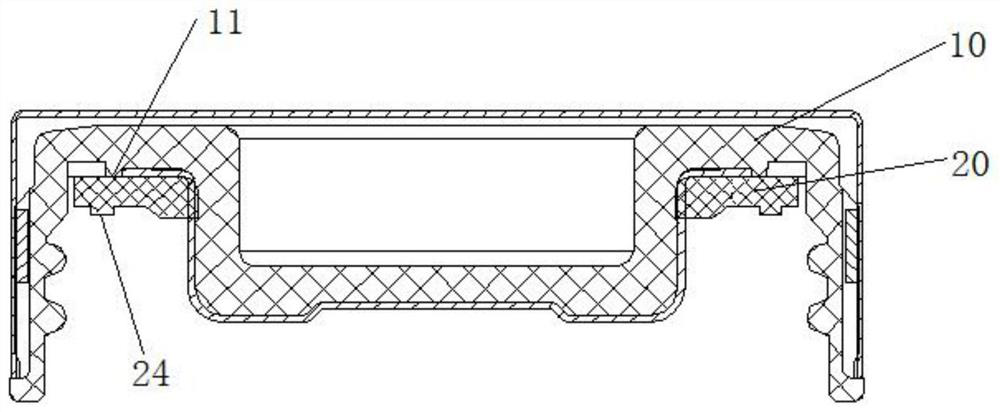

[0035] In some embodiments, such as figure 2 , Figure 4 and Figure 5 As shown, the inner side wall of the sealing ring 20 is equidistantly provided with a plurality of upwardly arranged primary exhaust grooves 21; the upper end surface of the sealing ring 20 is provided with secondary exhaust grooves 22 along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com