Temporary distribution box building device

A distribution box and temporary technology, applied in the substation/distribution device casing, substation/switch layout details, electrical components, etc., can solve the problem of difficult and rapid construction, and achieve the effect of convenient access and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

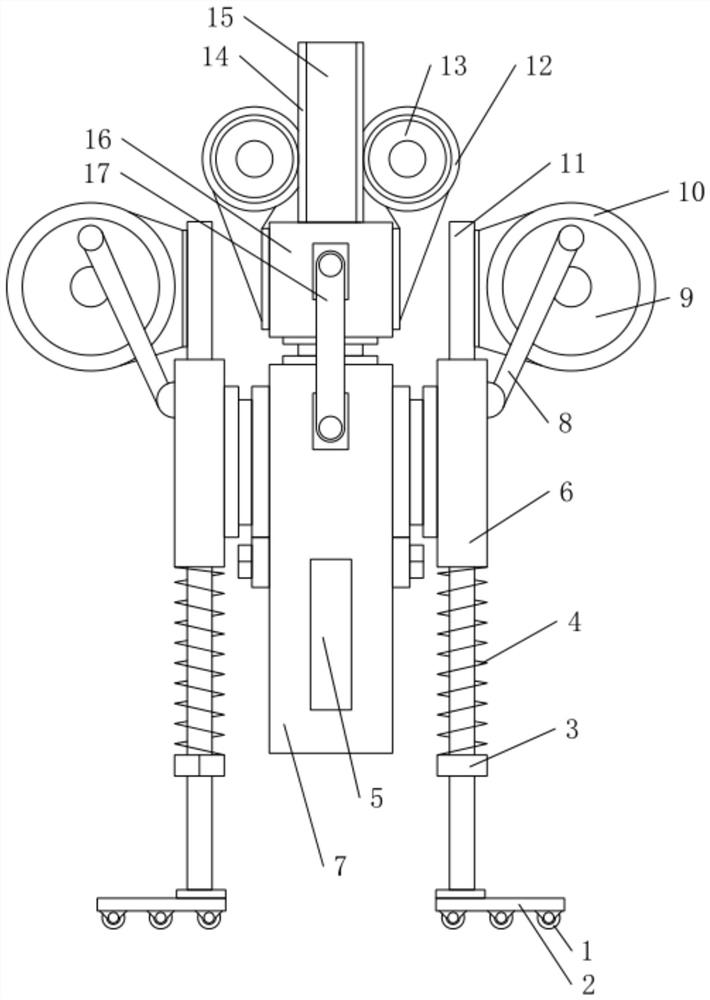

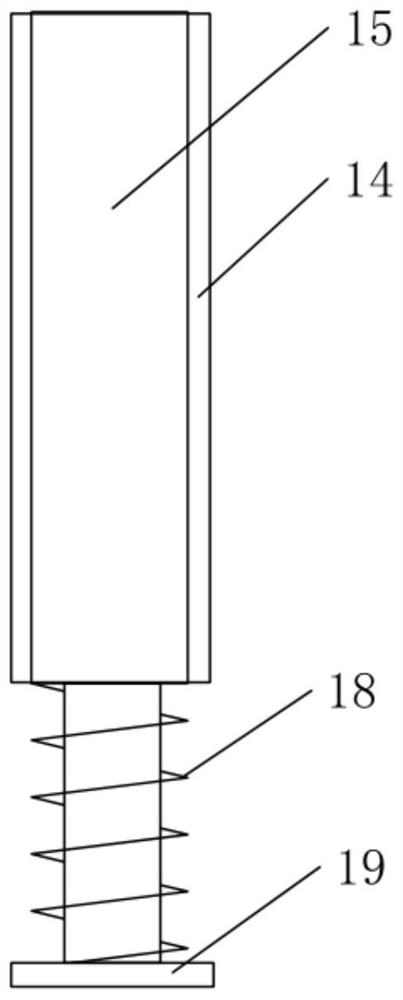

[0031] Such as figure 1 with figure 2 As shown, in this embodiment, the temporary distribution box construction device includes an insertion socket 7 , a push rod 19 , a driving mechanism, a guide rod 11 , a lifting mechanism and a second elastic member 4 . Wherein: the bottom end of inserting sleeve 7 is provided with opening, and push rod 19 slides and is placed in inserting sleeve 7, and driving mechanism is used for driving ejector rod 19 to slide up and down in inserting sleeve 7, and inserting sleeve 7 slides and is arranged on guide rod 11, guides The rod 11 extends vertically, and the insert 7 can slide relative to the guide rod 11 to have a first position and a second position. When the insert 7 is in the first position, the insert 7 is far away from the ground, and when the insert 7 is in the second position, the opening of the insertion socket 7 is inserted into the ground, the lifting mechanism is used to drive the insertion socket 7 to move from the second posit...

Embodiment 2

[0043] Embodiment 2 is the same as Embodiment 1 except for the lifting mechanism. The lifting mechanism in Embodiment 2 includes a first driving member, a gear and a rack. The first driving member is fixedly installed on the guide rod, and the gear is a half-circle toothed gear. , the gear is fixedly installed on the output end of the first driving member, the rack is fixedly installed on the first guide cylinder, and the rack and the gear mesh. The first driving part starts to drive the gear with only half a circle to rotate. When the toothed area of the gear is opposite to the rack, the gear drives the rack to move upward, and the rack drives the first guide cylinder to slide upward along the guide rod, and at the same time stretches the first guide cylinder. An elastic member, the first guide cylinder drives the inserting cylinder to move from the position inserted into the ground to a position away from the ground, when the toothless area of the gear is opposite to the ...

Embodiment 3

[0045] Embodiment 3 is the same as Embodiment 1 except for the driving mechanism. In Embodiment 3, the driving mechanism includes a cylinder and a push rod, the cylinder is fixedly installed on the second guide cylinder, the push rod is driven and matched with the cylinder, and the push rod is fixedly connected to the ejector sleeve . The cylinder drives the push rod to move downward, and the push rod drives the ejector sleeve to move downward, making it compress the first elastic member and drive the ejector rod to slide downward in the insert, pushing out the soil column formed in the insert.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com