Lock slider for slide fastener

A sliding head, lockable technology, applied in the direction of sliding fastener elements, applications, fasteners, etc., can solve problems such as being easily damaged, the locking element cannot be smoothly guided, and the sliding head is difficult to achieve rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

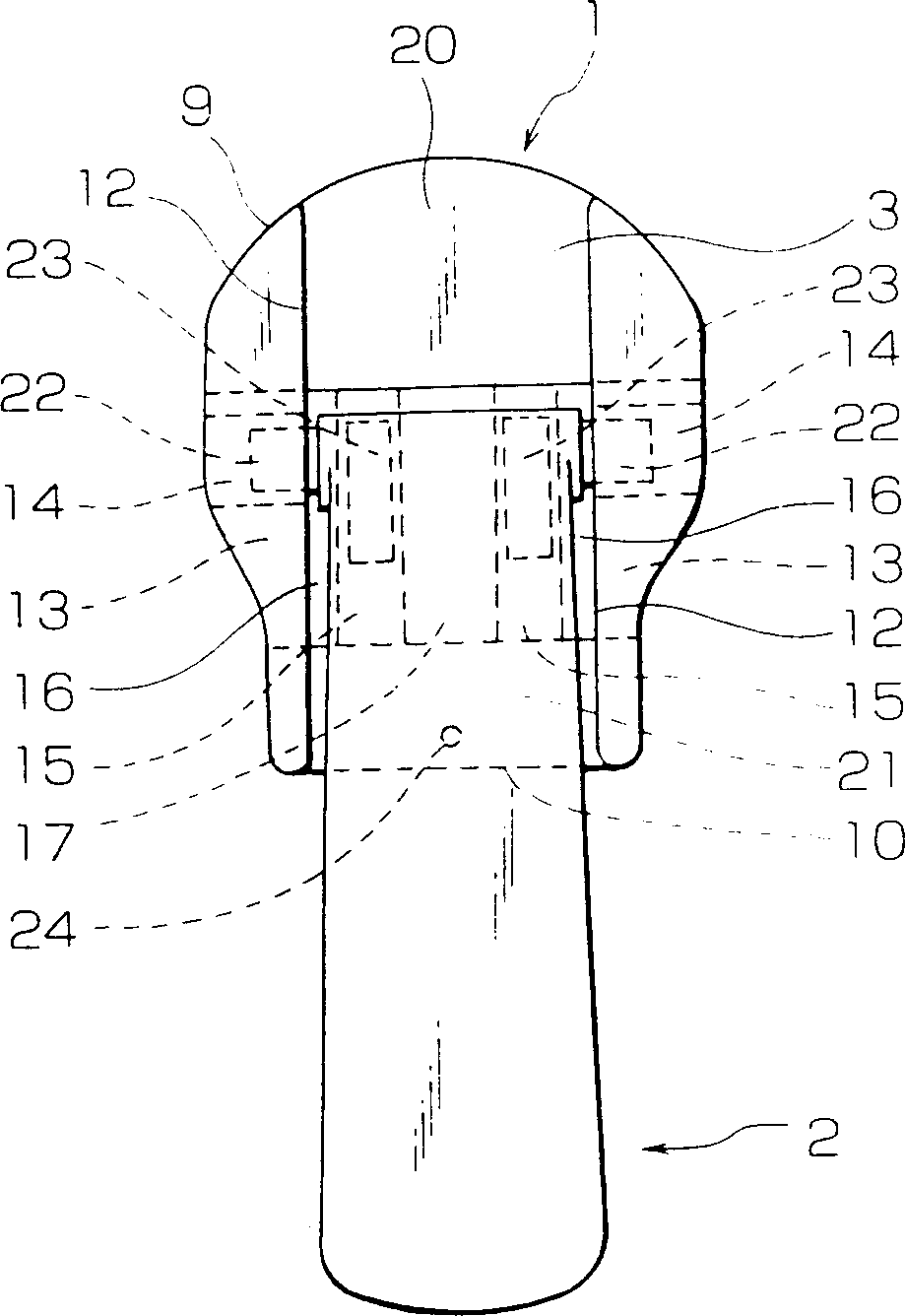

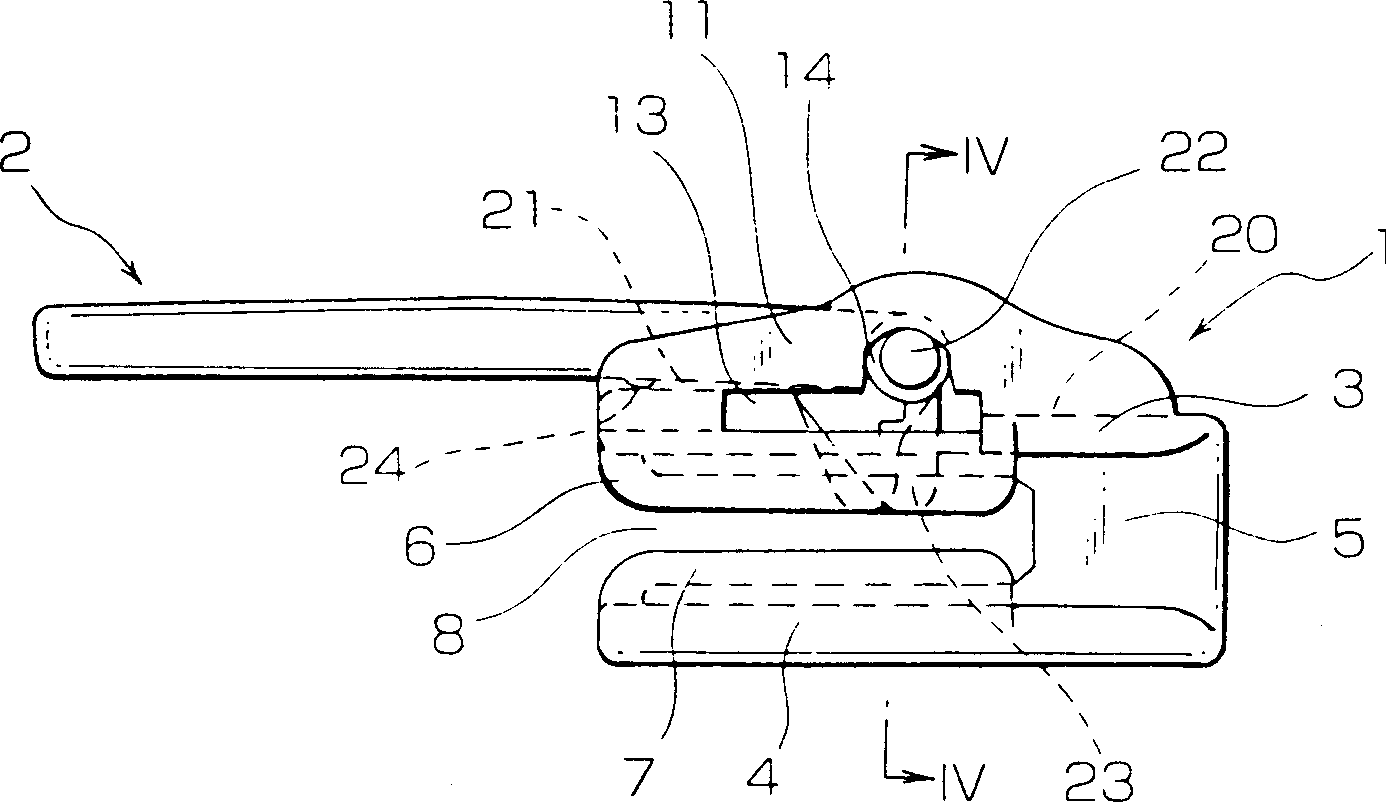

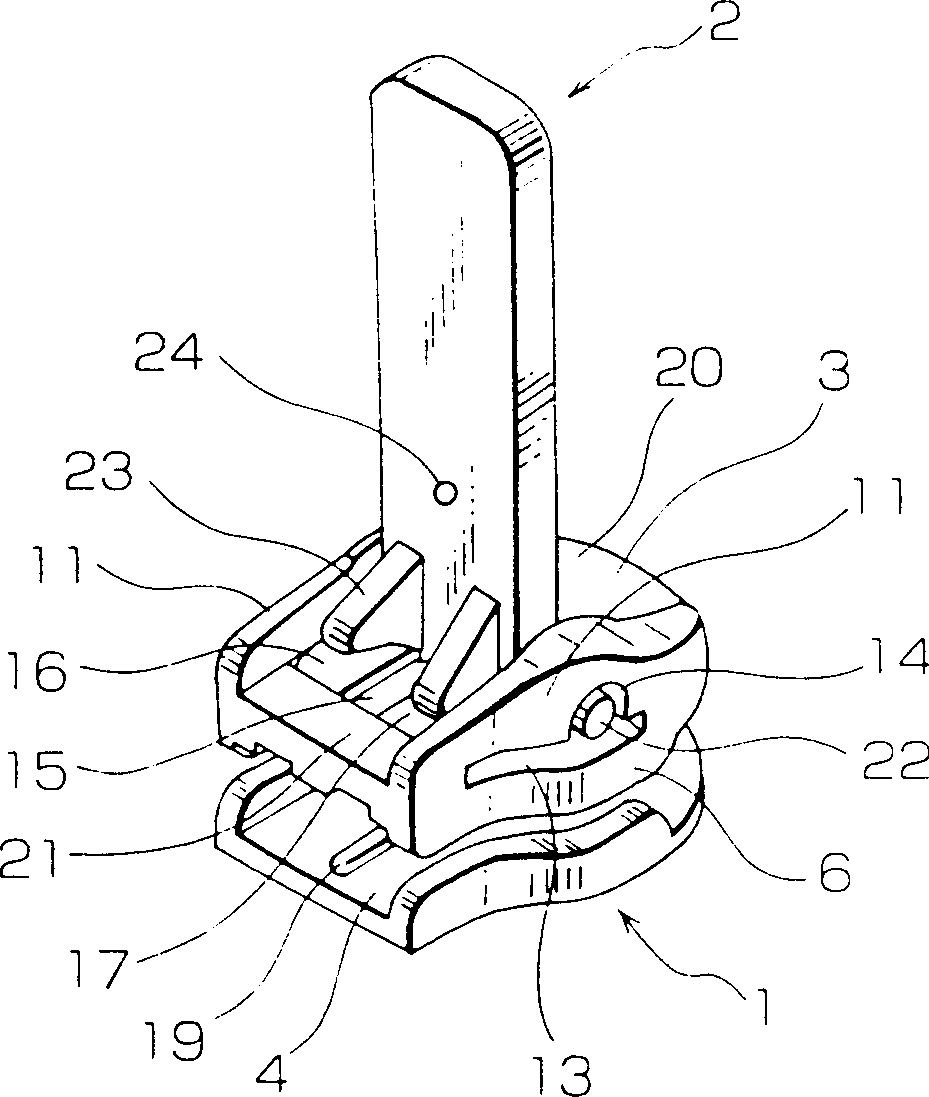

[0032] The preferred embodiments of the lockable sliding head for zipper according to the present invention will be described in detail below with reference to the accompanying drawings.

[0033] As shown in Figures 5 and 6, the lockable slider of the present invention can be worn on the following types of zippers (ziplock), for example, with two rows of braid B and sewing thread S sewn across the zipper tape 7 A type in which the continuous fasteners E on the inner longitudinal sides of the zipper tape T and each row is composed of a zigzag-shaped monofilament, or two rows are installed on the inner longitudinal length of the zipper tape T by molding or nail The type of discrete locks on the side.

[0034] In addition, the lockable slider can also be used for a type of zipper (zip) that has two rows of looped or zigzag-shaped fasteners and each row is mounted on one surface of the zipper tape.

[0035] As shown in FIGS. 1 to 4, the lockable slider according to the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com