Goods distribution method and equipment and computer readable storage medium

A distribution method and computer technology, applied in the field of communication, can solve problems such as distribution of goods, and achieve the effect of improving intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

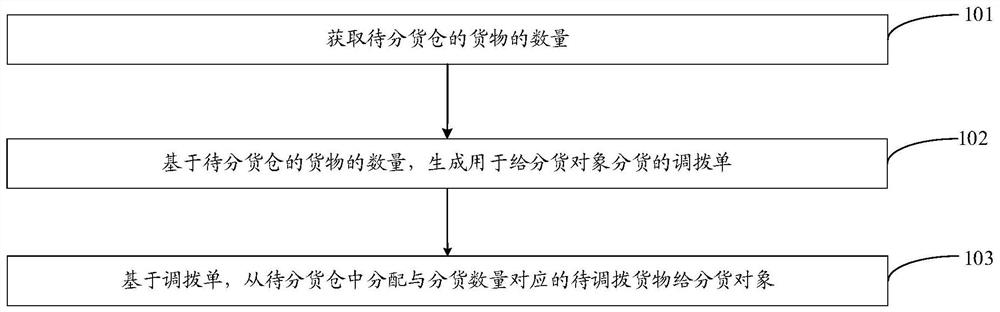

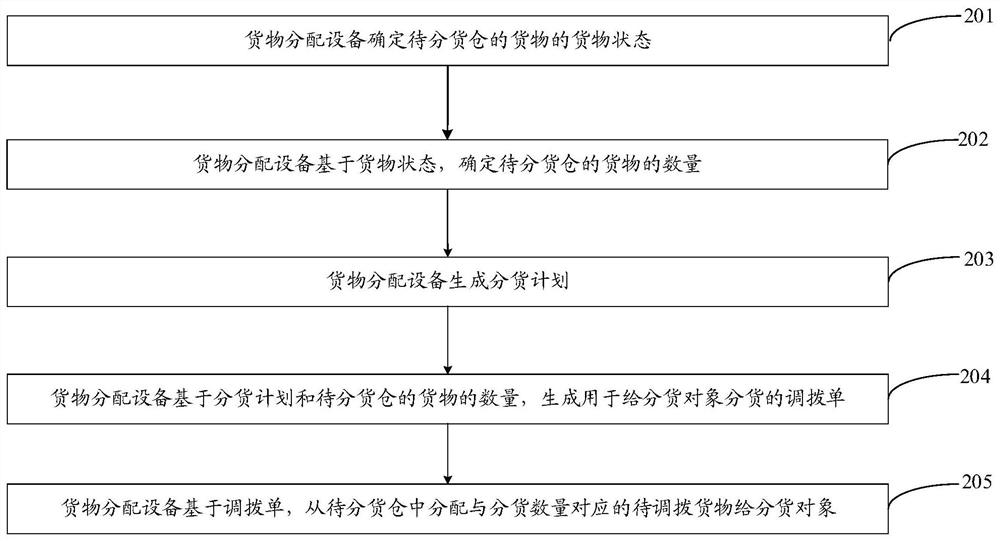

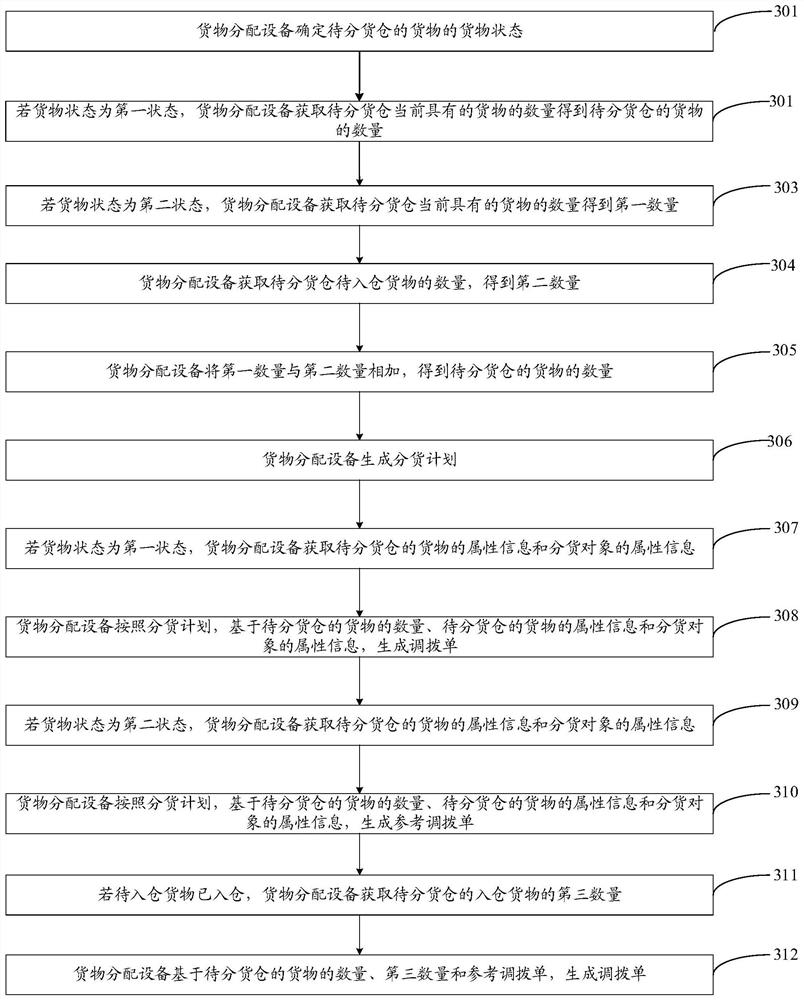

[0052] An embodiment of the present invention provides a method for distributing goods, referring to figure 1 As shown, the method includes the following steps:

[0053] Step 101, acquire the quantity of goods in the warehouse to be sorted.

[0054] Wherein, step 101 to acquire the quantity of goods in the warehouse to be divided can be realized by goods distribution equipment; the warehouse to be divided can be an intermediate warehouse in the supply chain system, and of course, the warehouse to be divided can also be any warehouse that can store goods . The quantity of goods in the warehouse to be divided may refer to the quantity of all goods in the warehouse to be divided, or may refer to the respective quantities of each kind of goods in the warehouse to be divided. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com