Gas-liquid separation device for sodium hypochlorite generator

A gas-liquid separation device, sodium hypochlorite technology, applied in separation methods, liquid degassing, chemical instruments and methods, etc., can solve the problems of liquid level fluctuations, large fluctuations, and reduced current efficiency, so as to save electricity costs, No pressure operation, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

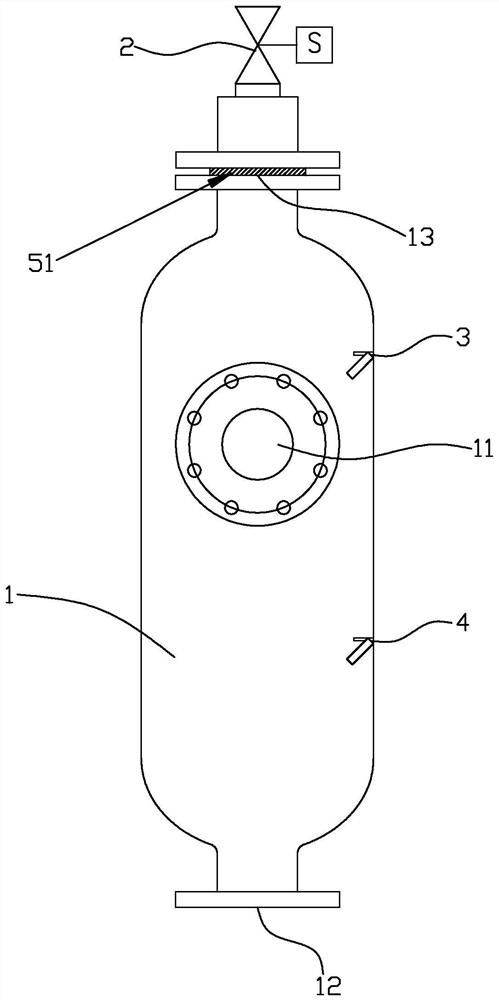

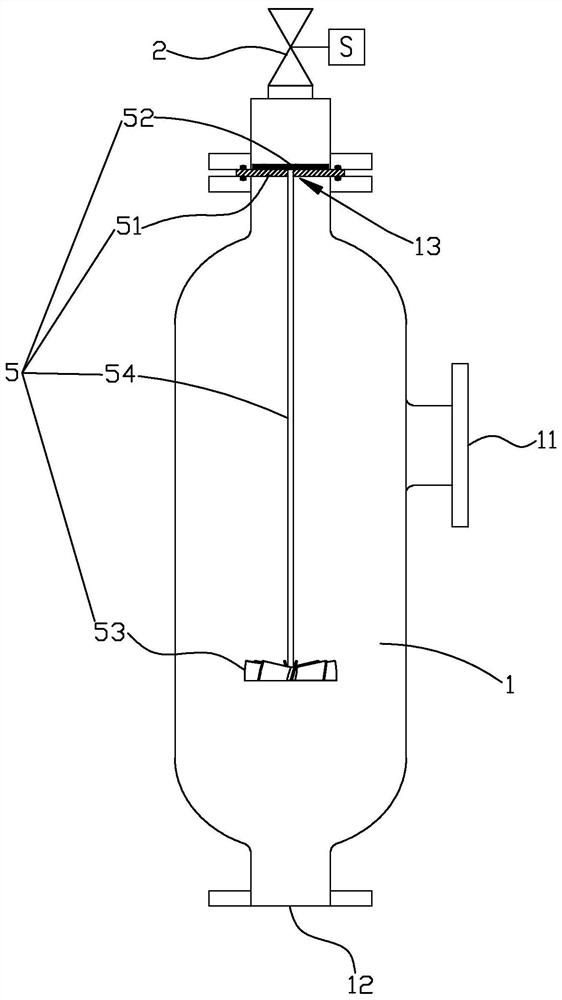

[0030] Such as Figure 1 to Figure 3 As shown, the gas-liquid separation device provided by the first embodiment of the present invention can be applied to the gas-liquid separation of the electrolysis product (sodium hypochlorite solution and hydrogen) of the sodium hypochlorite generator, and can quickly discharge the by-product hydrogen in the sodium hypochlorite solution.

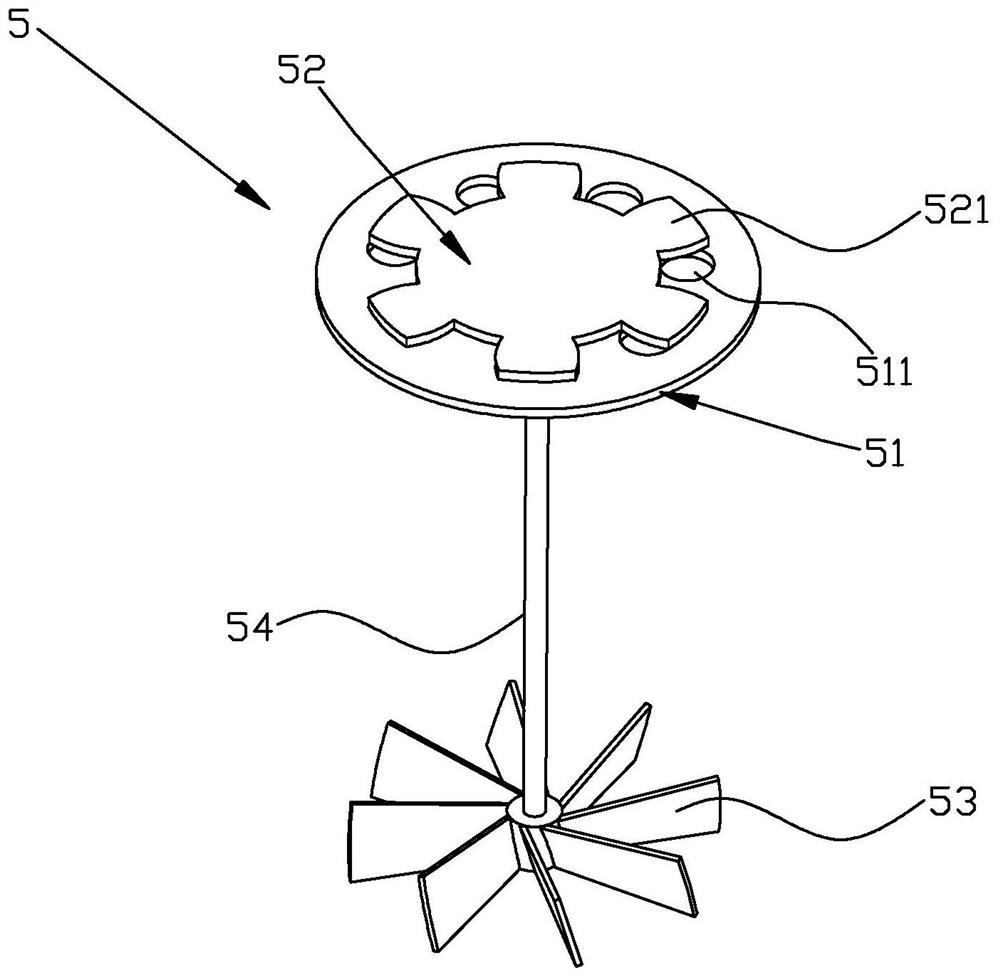

[0031] The gas-liquid separation device comprises a gas-liquid separation tank 1, the side wall of the gas-liquid separation tank 1 is provided with an inlet 11, the bottom of the gas-liquid separation tank 1 is provided with an outlet 12, and the top of the gas-liquid separation tank 1 is provided with an exhaust port 13 , the gas-liquid separation device also includes an exhaust assembly 5, and the exhaust assembly 5 includes an exhaust orifice plate 51, a rotating adjustment plate 52, a connecting rod 54 and a hydraulic rotating blade 53, and the exhaust orifice plate 51 is fixed on the bottom of the ...

no. 2 example

[0049] Such as Figure 6 and Figure 7 As shown, the gas-liquid separation device provided by the second embodiment of the present invention is basically the same as that of the first embodiment, except that the structure of the exhaust assembly 5 is different.

[0050] Specifically, in this embodiment, the top surface of the rotating adjustment plate 52 is attached to the bottom surface of the exhaust hole plate 51, the center of the exhaust hole plate 51 is provided with a first through hole 512, and the center of the rotation adjusting plate 52 A second through hole 522 is provided at the position, and the top end of the connecting rod 54 is inserted into the first through hole 512 after passing through the second through hole 522 , and the rotation adjusting plate 52 is fixedly connected with the connecting rod 54 through the second through hole 522 .

[0051] Preferably, a bearing 55 is disposed in the first through hole 512 , and the connecting rod 54 is inserted into t...

no. 3 example

[0054] Such as Figure 8 As shown, the gas-liquid separation device provided by the third embodiment of the present invention is substantially the same as that of the first embodiment, the difference is that this embodiment is also provided with a buffer tank 6 and a second exhaust solenoid valve 7, while the high liquid level sensor 3 It is different from the location where the low liquid level sensor 4 is set.

[0055] Specifically, in this embodiment, the gas-liquid separation device further includes a buffer tank 6 , the outlet 12 of the gas-liquid separation tank 1 protrudes into the buffer tank 6 , and a buffer tank outlet 61 is provided at the bottom of the buffer tank 6 .

[0056] Preferably, the gas-liquid separation device also includes a first exhaust solenoid valve 2, a high liquid level sensor 3 and a low liquid level sensor 4, the first exhaust solenoid valve 2 is arranged above the exhaust orifice plate 51, and the high liquid level sensor 3 and the low liquid ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap