Foul gas collecting and treating system for chemical industry sewage

A malodorous gas and treatment system technology, which is applied in the fields of air quality improvement, chemical instruments and methods, and separation of dispersed particles, can solve problems such as high risk of equipment operation, and achieve stable discharge standards, low cost, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

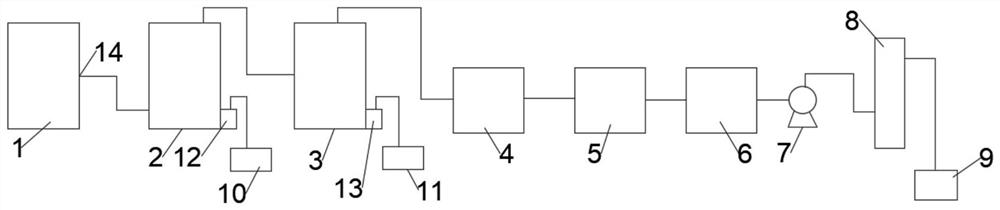

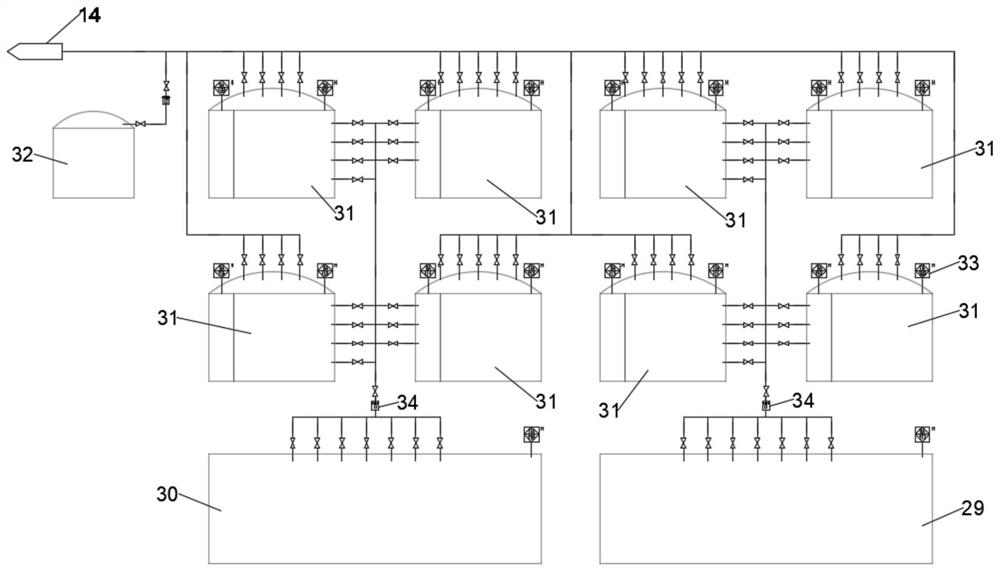

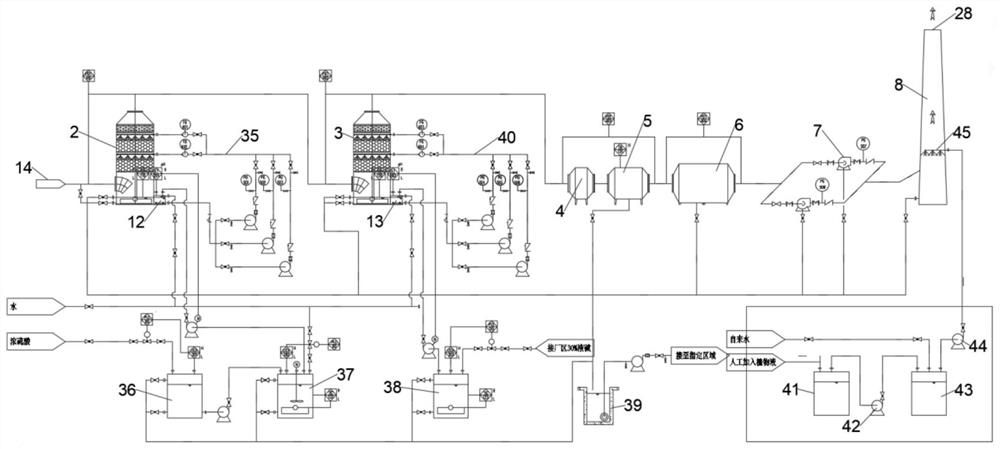

[0035] like Figure 1-Figure 3As shown, this embodiment provides a malodorous gas collection and treatment system for chemical sewage, including a malodorous gas collection device 1, an acid washing tower 2, an alkali washing tower 3, a demister 4, a UV photolysis reactor 5, and an activated carbon adsorption device 6. Induced fan 7, chimney 8 and plant gel treatment device 9.

[0036] Malodorous gas collecting device 1 is provided with malodorous gas collecting outlet pipe 14, and malodorous gas collecting outlet pipe 14 is communicated with the input end of pickling tower 2, and the output end of pickling tower 2 is communicated with the input end of alkali washing tower 3, and alkali washing tower The output end of 3 is communicated with the input end of mist eliminator 4, and the output end of mist eliminator 4 is communicated with the input end of UV photolysis reactor 5, and the output end of UV photolysis reactor 5 is connected with the input end of activated carbon ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com