Post-construction steel bar bender

A bending device and steel bar technology, applied in the field of bending devices, can solve the problems of labor-intensive, low work efficiency, cumbersome operation process, etc., and achieve the effect of improving work efficiency, simple operation and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

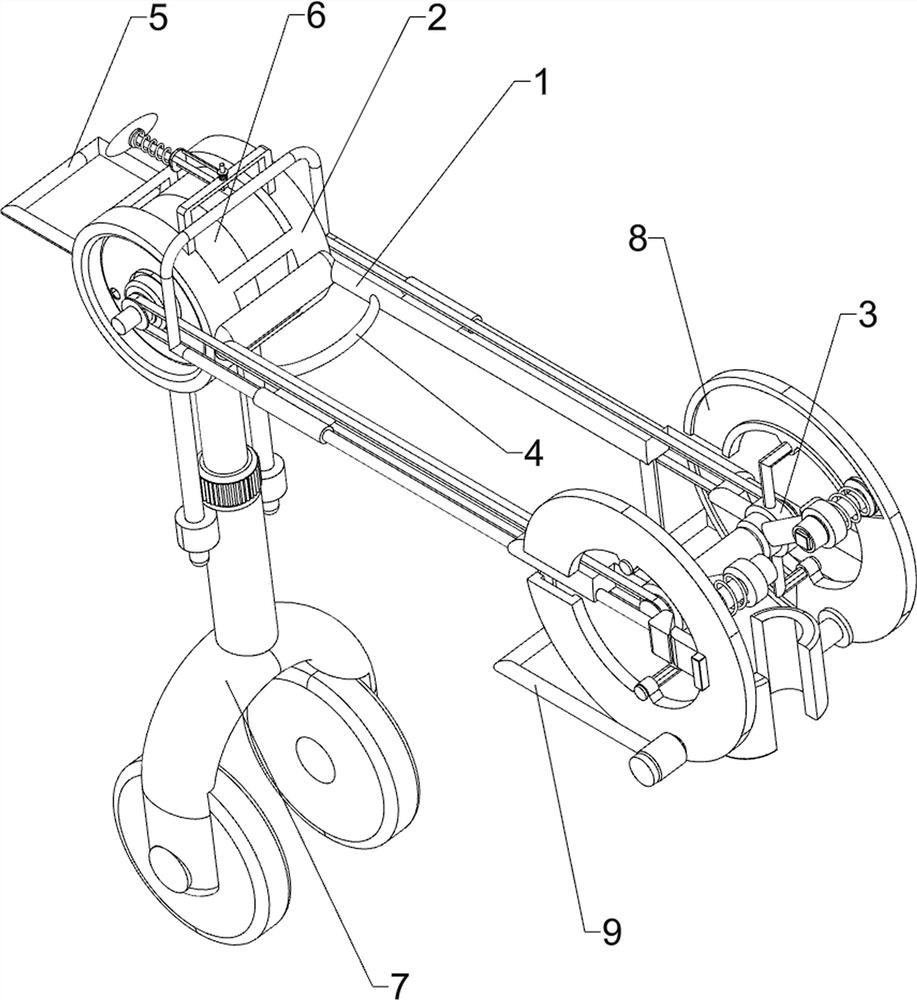

[0025] A post-construction bender for steel bars, such as figure 1 and figure 2 As shown, it includes a connecting frame 1, a mounting frame 2, a connecting bushing 3, a grip bar 4 and a pull rod 5, the left side of the connecting frame 1 is connected with the mounting frame 2, and the right side of the connecting frame 1 is connected with two connecting bushings 3, Two connecting bushes 3 are respectively connected to the front and rear sides of the connecting frame 1, the connecting frame 1 is connected with the handle bar 4, the installation frame 2 is connected with the pull rod 5, and also includes a bending assembly 6 and a moving assembly 7, the installation frame 2 A bending assembly 6 is provided between the connecting frame 1 and a moving assembly 7 is provided on the installation frame 2 .

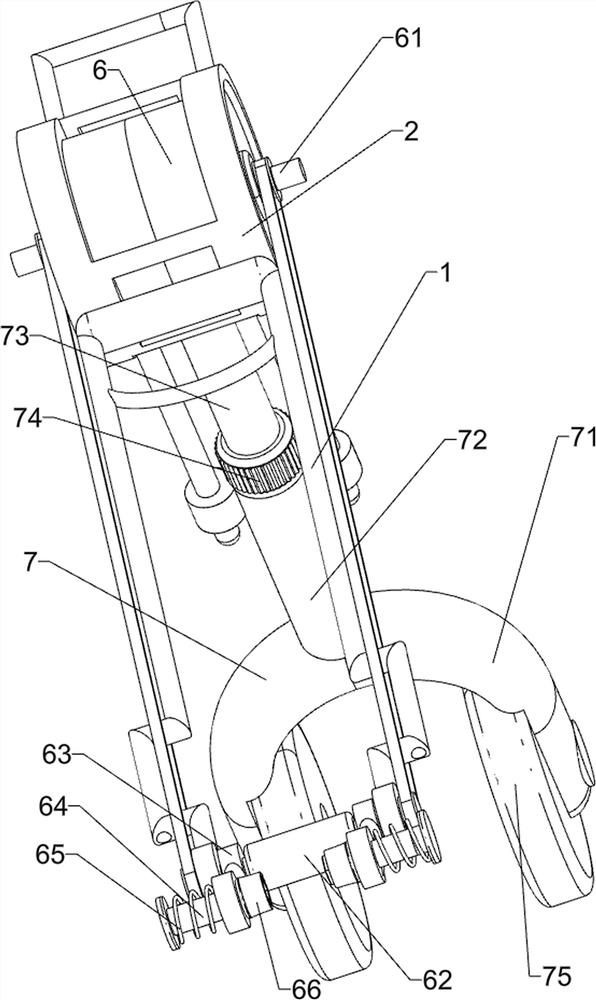

[0026] The bending assembly 6 includes a biaxial motor 61, a connecting shaft roller 62, a rotating swing lever 63, a slide bar 64, a return spring 65 and a pulley 66, and a b...

Embodiment 2

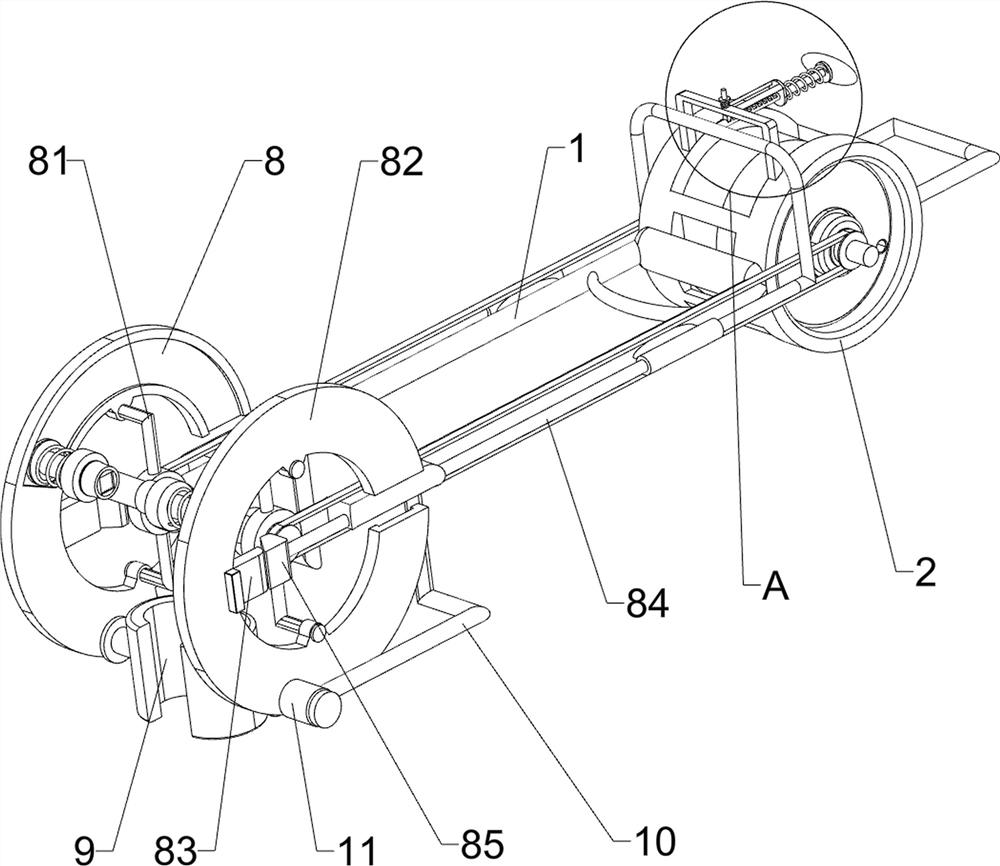

[0030] On the basis of Example 1, such as image 3 and Figure 4 As shown, a transmission assembly 8 is also included, and the transmission assembly 8 includes a clamping block 80, an L-shaped bar 81, a circular guide rail 82, a push block 83, a push rod 84, a wedge block 85, an n-shaped frame 86, a clamping rod 87, Connecting spring 88, vertical rod 89 and elastic member 90, L-shaped rods 81 are connected to the upper and lower sides of the connecting sleeve 3, and circular guide rails are slidingly connected between the two L-shaped rods 81 on the same connecting sleeve 3 82, the circular guide rail 82 is slidingly matched with the slide bar 64, the circular guide rail 82 is connected with a push block 83, the connecting frame 1 is slidably connected with a push rod 84, the front and rear sides of the push rod 84 are all connected with wedge blocks 85, wedge-shaped Block 85 cooperates with push block 83, and the top of installation frame 2 is connected with n-shaped frame 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com