Pipeline cutting equipment with supporting function

A pipe cutting and equipment technology, applied in the direction of shearing machine equipment, metal processing equipment, pipe shearing device, etc., can solve the problems of affecting pipe connection and uneven cutting surface, so as to improve friction, avoid vibration offset, and avoid deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

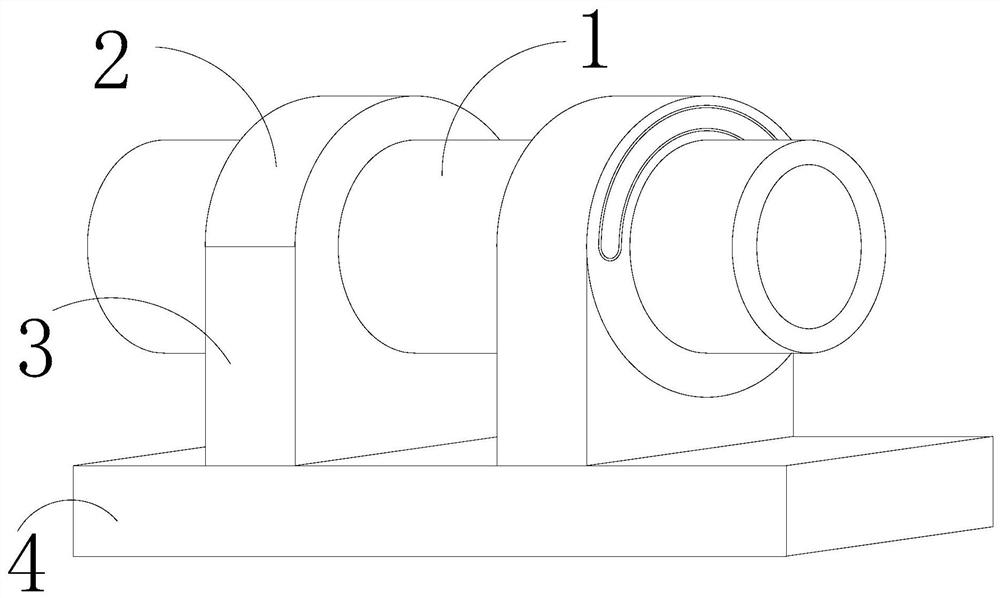

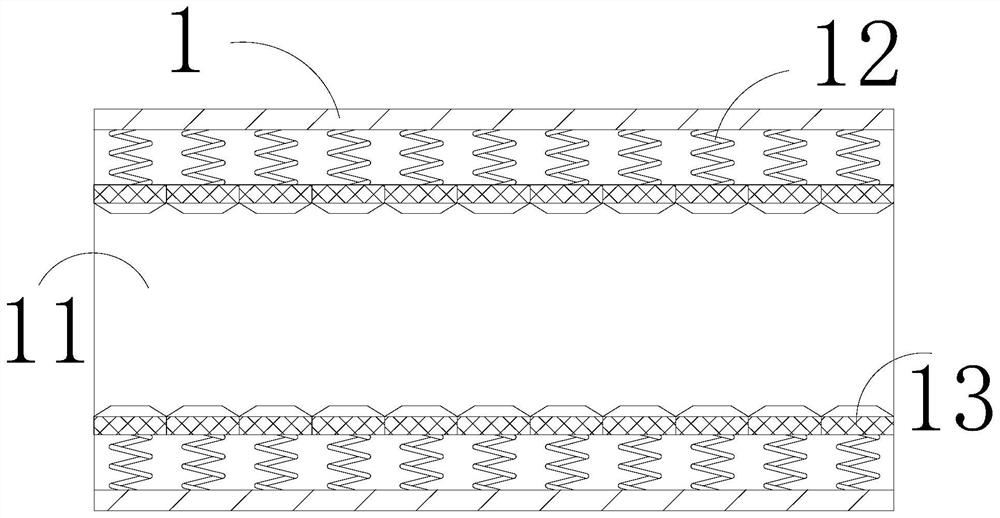

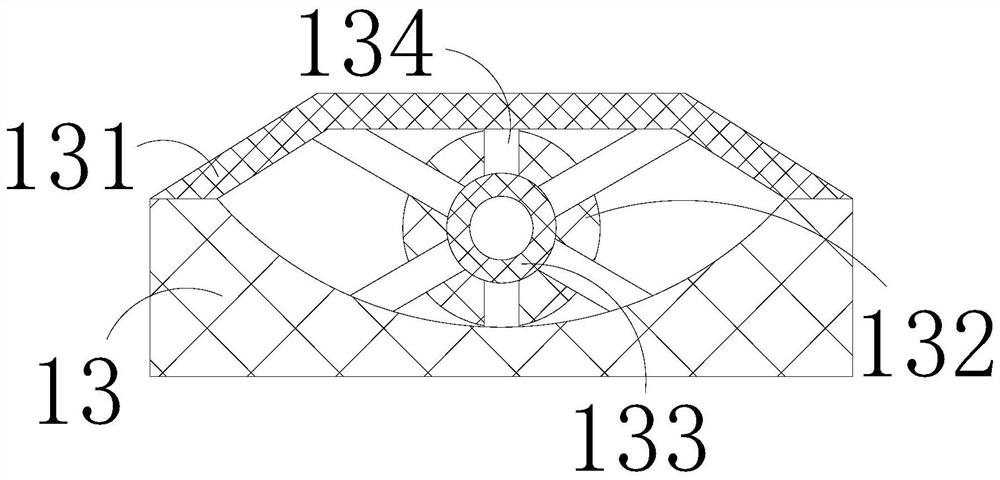

[0029] The present invention provides a pipe cutting equipment with support function, its structure includes a fixed cylinder 1, a cutter 2, a support plate 3, a base 4, the cutter 2 is nested in the outer periphery of the fixed cylinder 1, and the support plate 3 The upper surface is welded to the bottom of the fixed cylinder 1, the base 4 is connected to the bottom of the support plate 3 by welding, the fixed cylinder 1 includes a through pipe 11, a spring 12, and a clip 13, and the through pipe 11 is embedded in the fixed cylinder 1, one end of the spring 12 is embedded in the inner wall of the through pipe 11, and the clamp block 13 is connected to the other end of the spring 12 by welding. The left and right walls of 13 are smooth, and the thrust of the spring 12 to the clamp block 13 is greater than the gravity of the clamp block 13 itself, which is conducive to clamping the pipeline under the thrust of the spring 12 after the pipeline passes through the through pipe 11. ...

Embodiment 2

[0035] The present invention provides a pipe cutting equipment with support function, its structure includes a fixed cylinder 1, a cutter 2, a support plate 3, a base 4, the cutter 2 is nested in the outer periphery of the fixed cylinder 1, and the support plate 3 The upper surface is welded to the bottom of the fixed cylinder 1, the base 4 is connected to the bottom of the support plate 3 by welding, the fixed cylinder 1 includes a through pipe 11, a spring 12, and a clip 13, and the through pipe 11 is embedded in the fixed cylinder 1, one end of the spring 12 is embedded in the inner wall of the through pipe 11, and the clamp block 13 is connected to the other end of the spring 12 by welding. The left and right walls of 13 are smooth, and the thrust of the spring 12 to the clamp block 13 is greater than the gravity of the clamp block 13 itself, which is conducive to clamping the pipeline under the thrust of the spring 12 after the pipeline passes through the through pipe 11. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com