Refrigerator and Refrigerator Defrosting Control Method

A control method and refrigerator technology, which are applied to the defrosting control of refrigerators and the field of refrigerator control, can solve the problems of inaccurate temperature detection by a defrosting temperature sensor, inaccurate refrigerators, and clean discharge, so as to avoid working too long or too short. , The effect of saving product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

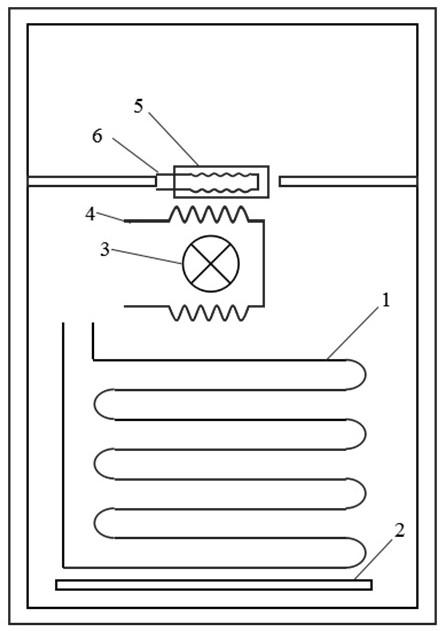

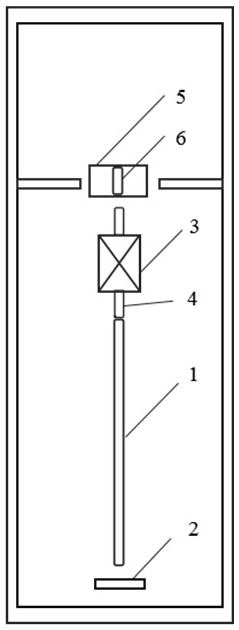

[0044] Such as Figure 1-2 As shown, this embodiment provides a refrigerator, which includes: an evaporator 1 , a defrosting heater 2 , a freezing fan 3 , a fan defrosting heating wire 4 , a freezing and refrigerating damper 5 , and a fan defrosting heating wire 6 . Compared with the existing refrigerator, heating wires for the freezing air duct are added, and the heating wires for the freezing air duct include fan defrosting heating wires 4 and damper defrosting heating wires 6 . The fan defrosting heating wire 4 is half surrounded on the outside of the freezing fan 3 , and the heating part of the damper defrosting heating wire 6 is arranged in the freezing and refrigerating damper 5 .

[0045] When the refrigerator is in the cooling mode, the compressor starts, the heating wire of the freezing air duct and the defrosting heater 2 are closed, the freezing and refrigerating damper 5 is opened, and the freezing fan 3 is started; Shut down, the freezing air duct heating wire an...

Embodiment 2

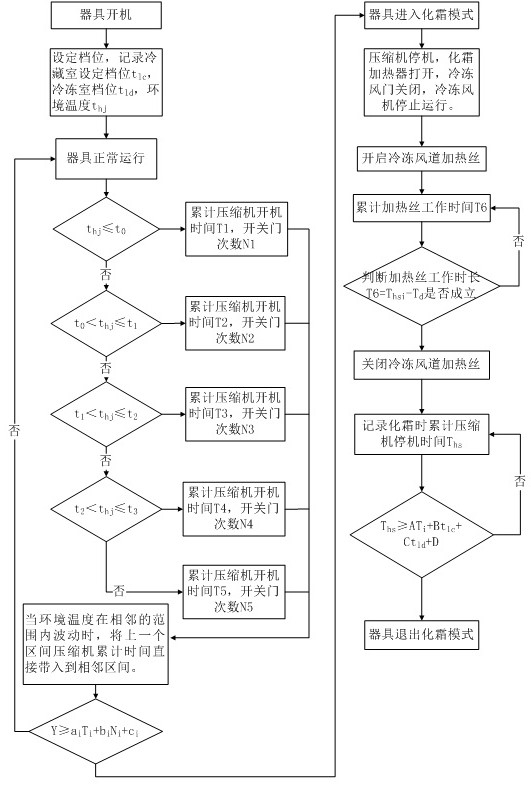

[0047] This embodiment provides a defrosting control method for a refrigerator. The internal volume of the refrigerator described in this embodiment is 500 L. The internal structure of the refrigerator is consistent with that of the refrigerator provided in Example 1. The defrosting control method Process such as figure 2 shown, including:

[0048] S1, set and record the refrigerating compartment gear t of the refrigerator lc , set and record the freezer stall t of the refrigerator ld , the refrigerator is in cooling mode at this time;

[0049] S2, detect and record the ambient temperature t outside the refrigerator hj , set five consecutive temperature zones from high temperature to low temperature, set the temperature zone less than or equal to 10°C as the first temperature zone, set the temperature zone greater than 10°C and less than or equal to 20°C as the second temperature zone, set The temperature range greater than 20°C and less than or equal to 30°C is defined a...

Embodiment 3

[0054] This embodiment provides a defrosting control method for a refrigerator. The internal volume of the refrigerator described in this embodiment is 400 L. The internal structure of the refrigerator is consistent with that of the refrigerator provided in Embodiment 1. The defrosting control method includes :

[0055] S1, set and record the refrigerating compartment gear t of the refrigerator lc , set and record the freezer stall t of the refrigerator ld , the refrigerator is in cooling mode at this time;

[0056] S2, detect and record the ambient temperature t outside the refrigerator hj , set five consecutive temperature zones from high temperature to low temperature, set the temperature zone less than or equal to 10°C as the first temperature zone, set the temperature zone greater than 10°C and less than or equal to 20°C as the second temperature zone, set The temperature range greater than 20°C and less than or equal to 30°C is defined as the third temperature range, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com