Shockproof new energy automobile battery fixing device

A new energy vehicle, battery fixing technology, applied in electric power devices, secondary batteries, power devices, etc., can solve problems such as affecting work efficiency, easy battery fall off, easy heat generation during battery use time, etc., to avoid excessive temperature, Less bumpy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

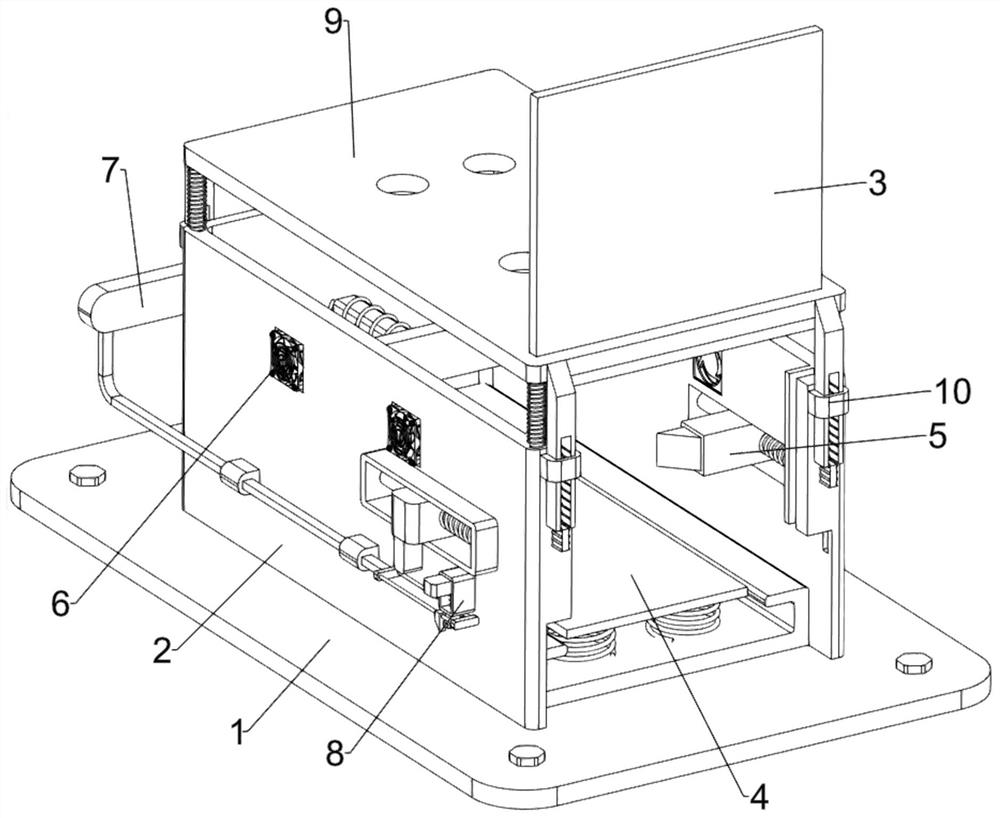

[0027] A shockproof new energy vehicle battery fixing device, such as Figure 1-Figure 3 As shown, it includes a base 1, an outer frame 2, a side plate 3, a bottom shock absorbing mechanism 4 and a clamping mechanism 5. The outer frame 2 is fixedly connected to the top of the base 1, and the left and right sides of the outer frame 2 are slidingly arranged at the front. The side plate 3 is provided with a bottom damping mechanism 4 on the base 1 , and the outer frame 2 is provided with a clamping mechanism 5 .

[0028] The bottom damping mechanism 4 includes a limiting plate 41, a first spring 42 and a first shock absorbing plate 43. The limiting plate 41 is fixedly connected to the top of the base 1, and the limiting plate 41 is located in the outer frame 2. The inner top of the limiting plate 41 is uniform First springs 42 are fixedly connected at intervals, and first damping plates 43 are fixedly connected between tail ends of the first springs 42 .

[0029] The clamping me...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , Figure 4 and Figure 5 As shown, a heat dissipation fan 6 is also included, and the left and right sides of the outer frame 2 are symmetrically provided with a heat dissipation fan 6 .

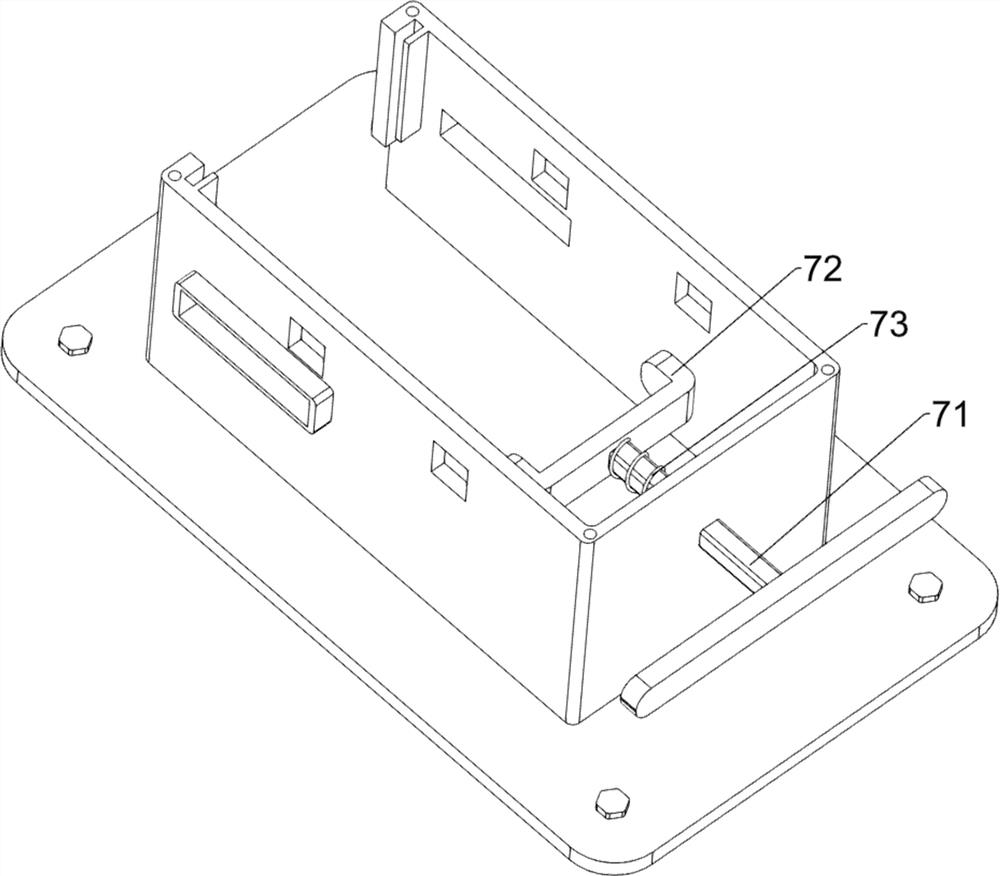

[0035] Also includes a guide mechanism 7, the guide mechanism 7 includes a first connecting rod 71, a first block 72 and a fourth spring 73, the outer frame 2 is provided with a first connecting rod 71 sliding in the middle of the rear side, and the first connecting rod 71 A first block 72 is fixedly connected to the front end, and a fourth spring 73 is fixedly connected between the middle part of the rear side of the first block 72 and the middle part of the inner rear side of the outer frame 2 , and the fourth spring 73 is sleeved on the first connecting rod 71 .

[0036]Also include control mechanism 8, control mechanism 8 includes first guide block 81, second connecting rod 82, third connecting rod 83, second wedge block 84, guide fra...

Embodiment 3

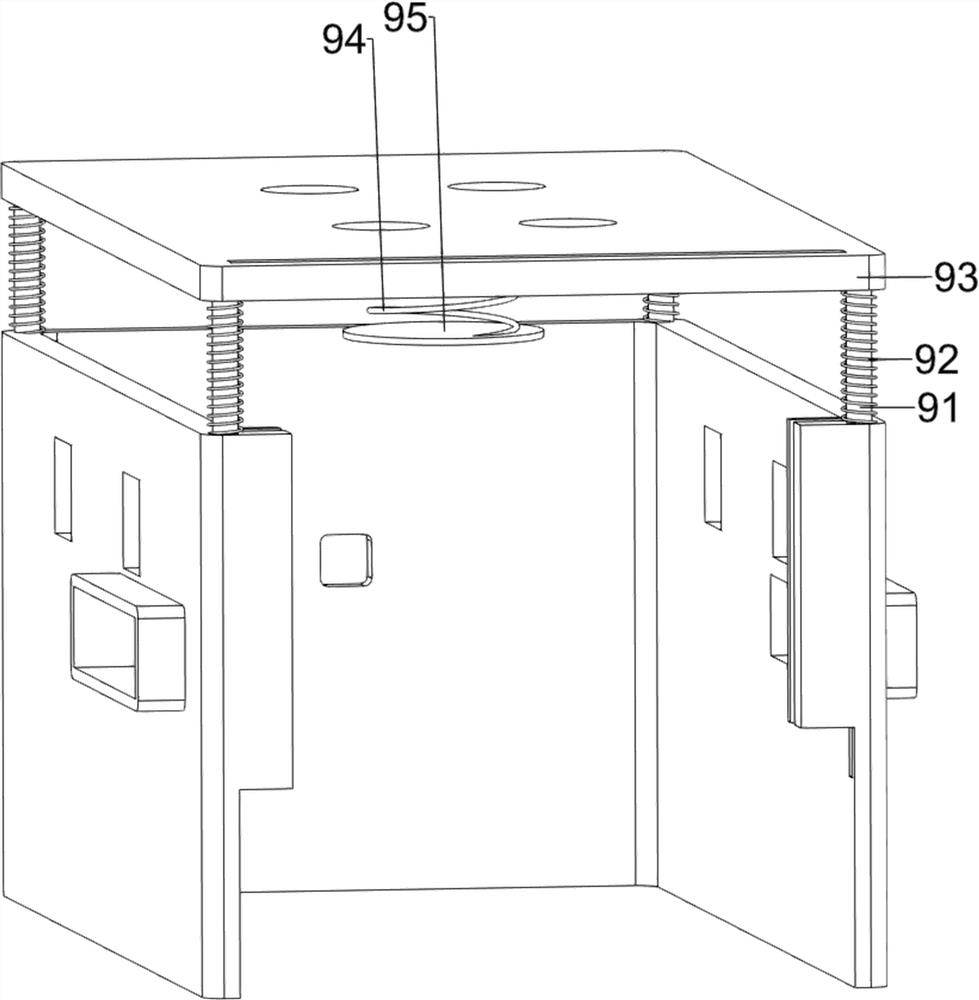

[0041] On the basis of embodiment 1 and embodiment 2, such as figure 1 , Figure 6 and Figure 7 As shown, it also includes a top damping mechanism 9, the top damping mechanism 9 includes a third guide rod 91, a sixth spring 92, a top plate 93, a seventh spring 94 and a second shock absorbing plate 95, and the top of the outer frame 2 is uniform The spaced sliding type is provided with four third guide rods 91, a top plate 93 is fixedly connected between the tops of the four third guide rods 91, and four sixth springs are fixedly connected between the bottom of the top plate 93 and the top of the outer frame 2 at even intervals. 92 , the sixth spring 92 is sleeved on the third guide rod 91 , the seventh spring 94 is affixed in the middle of the bottom of the top plate 93 , and the second damping plate 95 is affixed to the tail end of the seventh spring 94 .

[0042] Also includes a locking mechanism 10, the locking mechanism 10 includes a second guide block 101, a rack bar 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com