Gear tooth profile positioning and milling device for producing planetary gear speed reducer

A planetary gear deceleration and gear tooth profile technology, applied in gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems of inconvenient operation, complex structure, hidden safety hazards, etc., and achieve easy-to-understand operating principles, simple equipment components, The effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

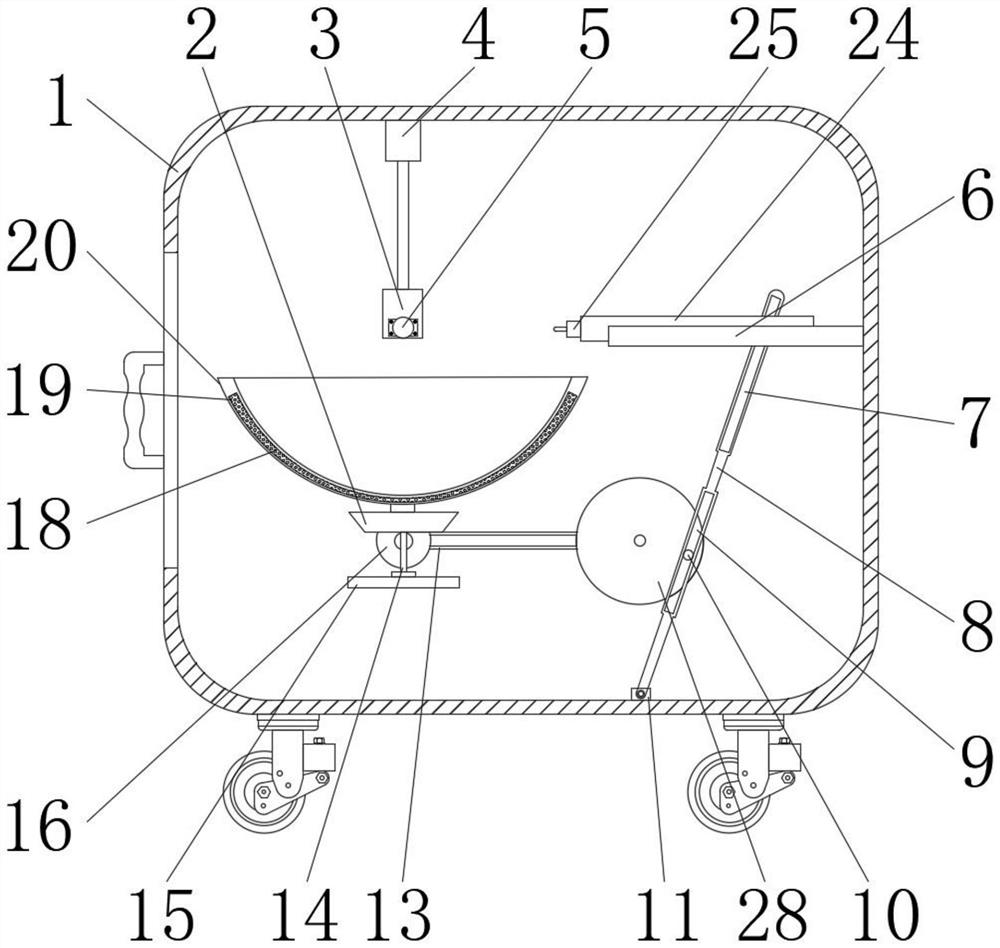

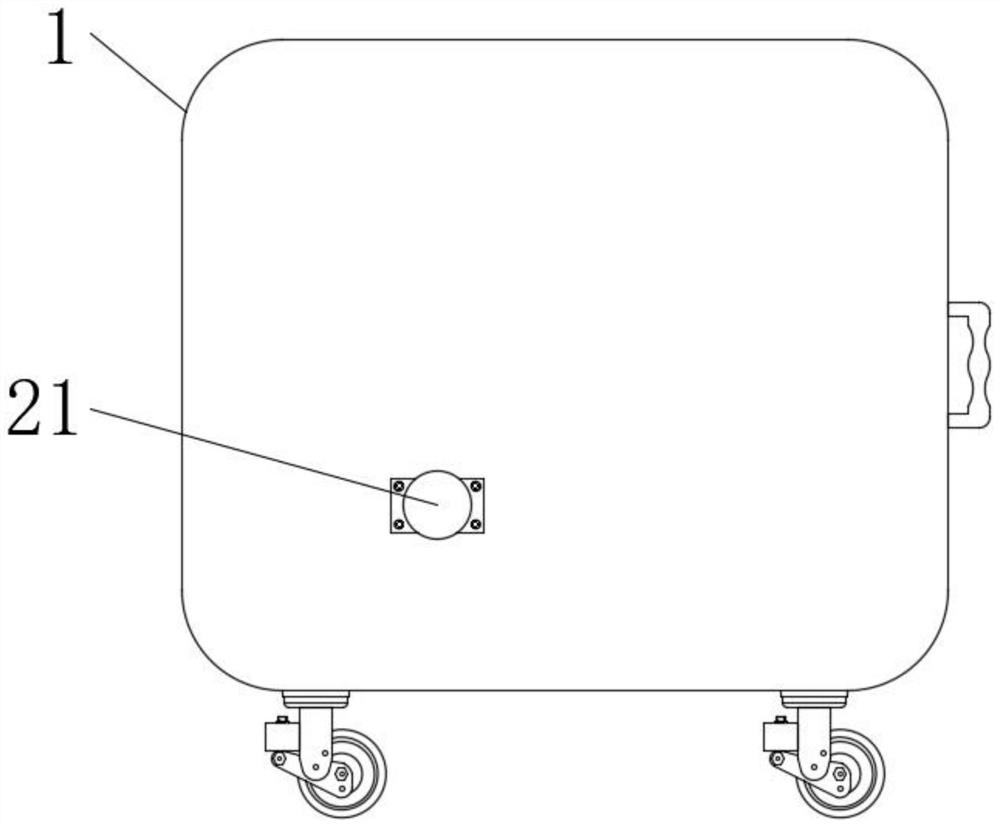

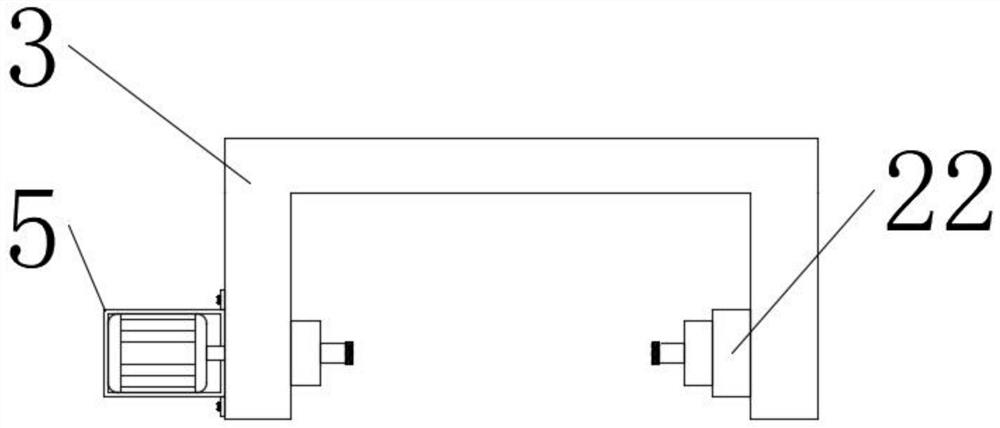

[0028] Such as Figure 1-7 As shown, the embodiment of the present invention provides a gear tooth profile positioning milling device for planetary gear reducer production, including a box body 1, a brake cylinder 4, an electric push rod 22, a milling cutter 25, a first motor 5 and a second motor 21. The inside of the box body 1 is provided with a drive plate 28, the position of the positive side wall of the drive plate 28 close to the edge is fixedly connected with the fixed shaft 10, the inside of the box body 1 is provided with a drive rod 8, and the inside of the drive rod 8 is respectively provided with The drive groove 7 and the transmission groove 9, the drive rod 8 is rotated and socketed on the outer surface of the fixed shaft 10 through the transmission groove 9, and the connecting frame 11 is arranged directly below the driving disk 28, and the connecting frame 11 is fixedly connected with the inner bottom of the box body 1 One end of the driving rod 8 close to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com