Automobile safety belt limiting buckle mounting clamp for high-end equipment manufacturing

A technology of limit buckle and seat belt, applied in the field of auto parts manufacturing, can solve the problems of reduced installation accuracy, easy falling of the limit buckle, inability to realize automatic tightening of seat belts, etc., so as to improve installation accuracy and quickly find accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

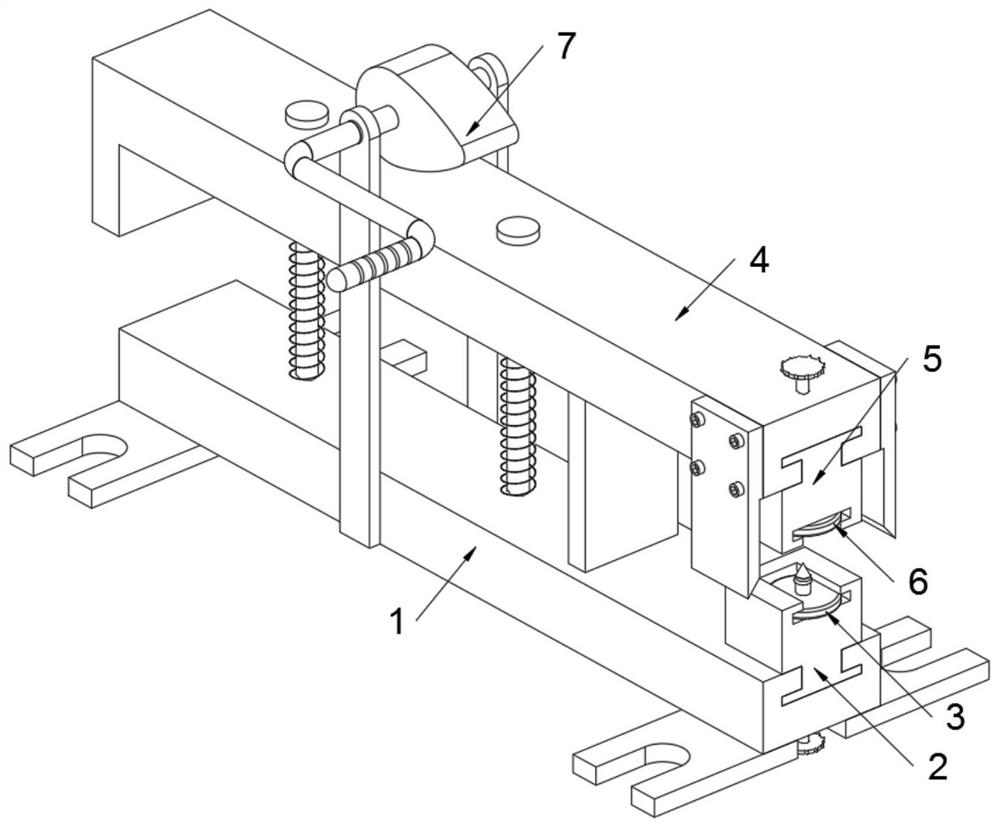

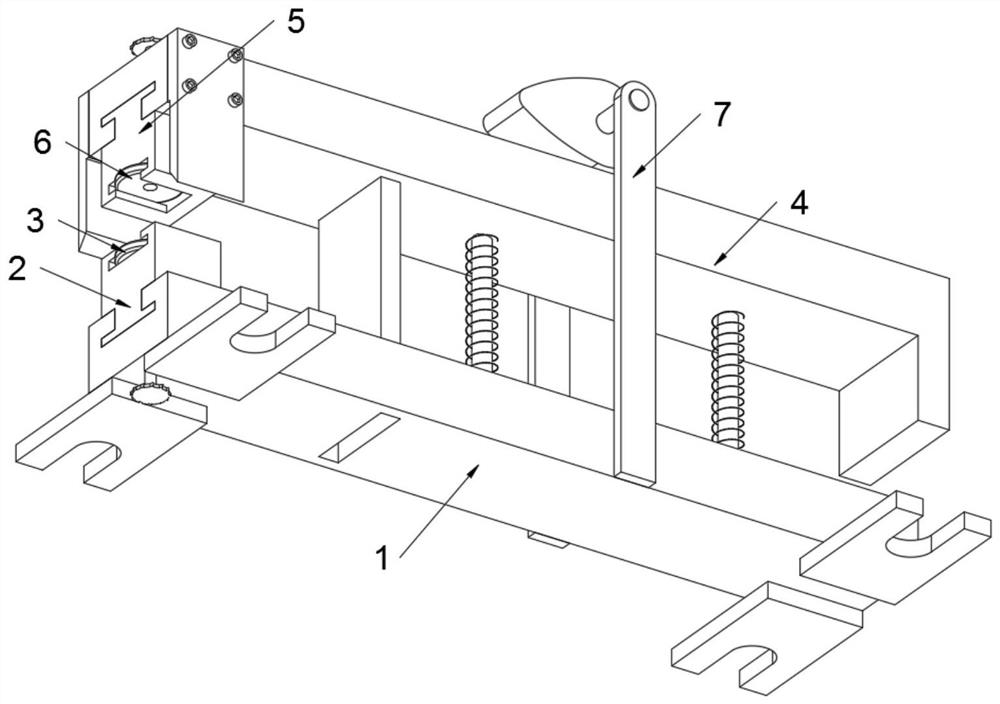

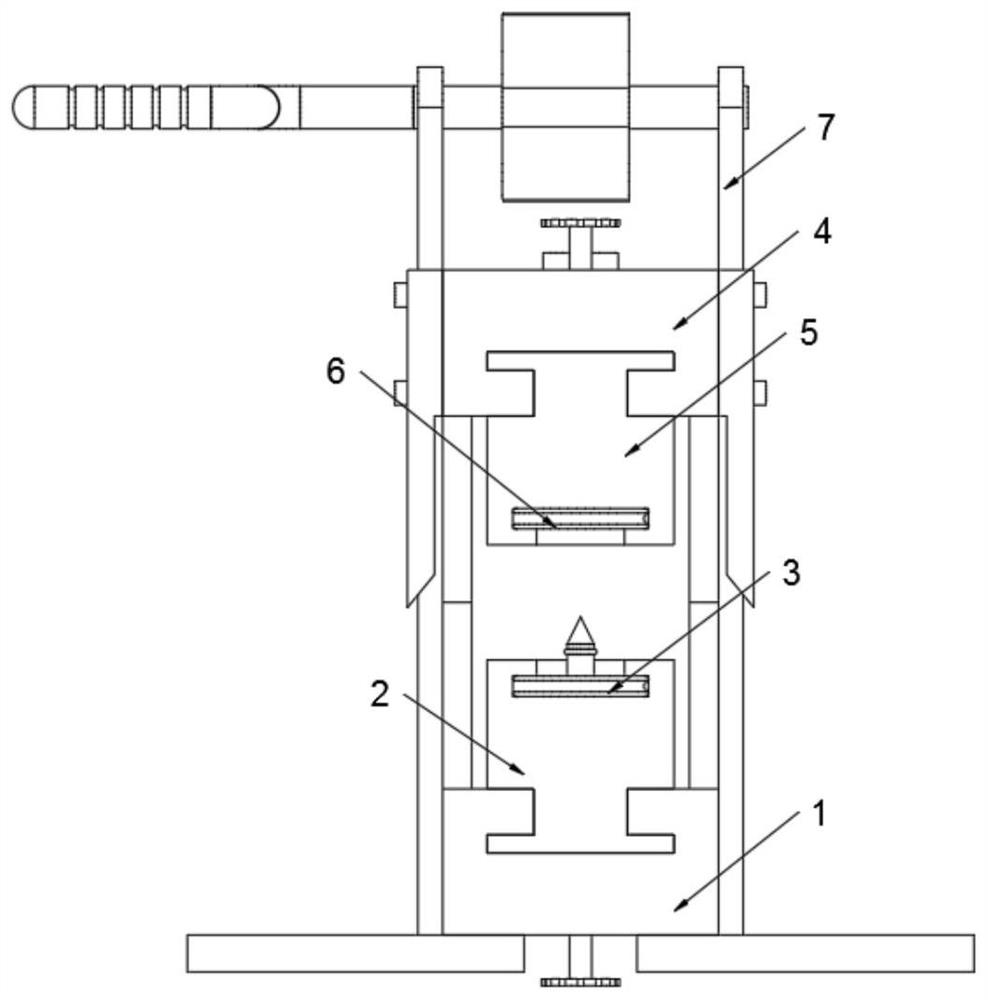

[0036] as attached figure 1 To attach Figure 8 Shown:

[0037] The present invention provides a high-end equipment manufacturing automotive safety belt limit buckle installation pliers, including a base 1; a placement seat A2 is installed on the base 1, and a limit buckle male head 3 is placed in the placement seat A2; Pressing seat 4, and the placing seat B5 is installed on the pressing seat 4, and the limited buckle female head 6 is placed in the placing seat B5; the driving structure 7 is welded on the base 1; refer to as Figure 4 , the base 1 includes a rectangular hole 106, and a rectangular hole 106 is provided on the base 1; the extrusion seat 4 also includes a rectangular plate 403, and a rectangular plate 403 is welded on the bottom surface of the extrusion seat 4, and the rectangular plate 403 and the rectangular hole 106 are positioned Alignment: When the safety belt touches the rectangular plate 403, the male head 3 of the limit buckle and the female head 6 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com