Large glass local film pasting machine

A film laminating machine and glass technology, applied in the field of local laminating machines, can solve the problems of film quality not meeting requirements, low film efficiency, inconvenient production and processing, etc., to achieve the effect of low labor cost, high production efficiency, and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

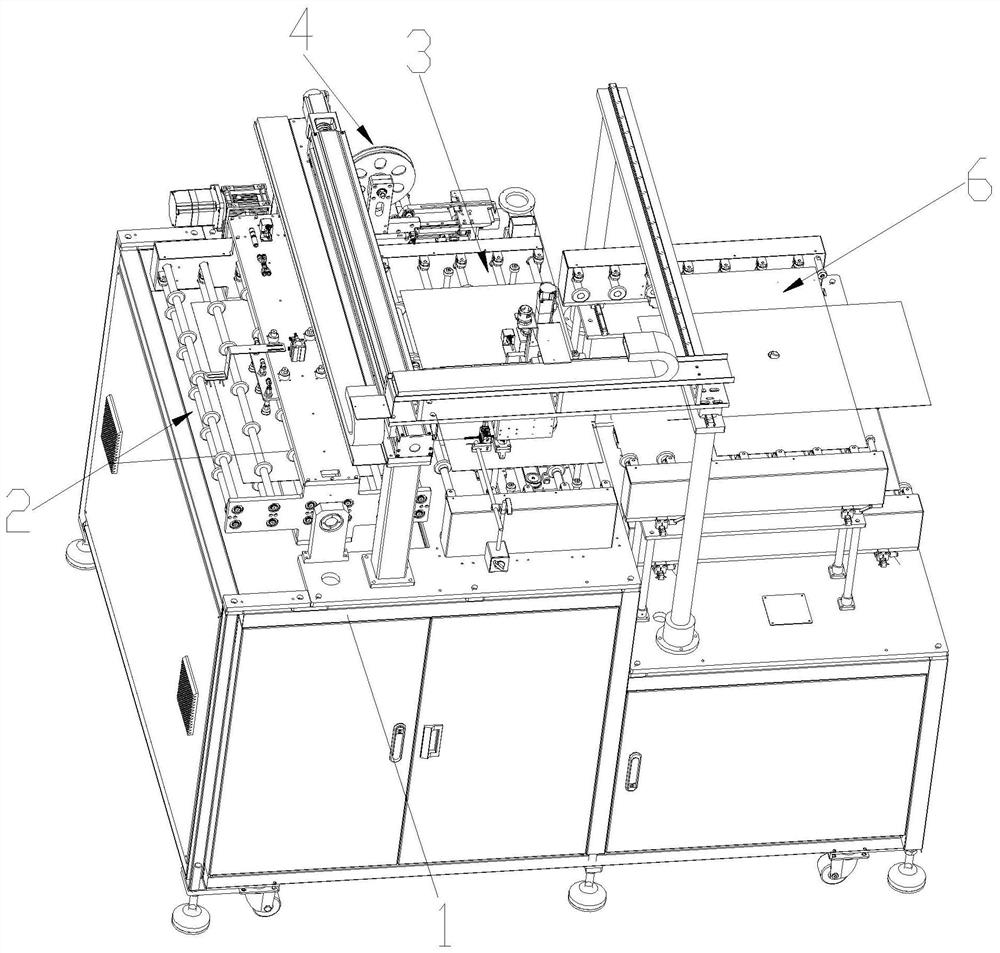

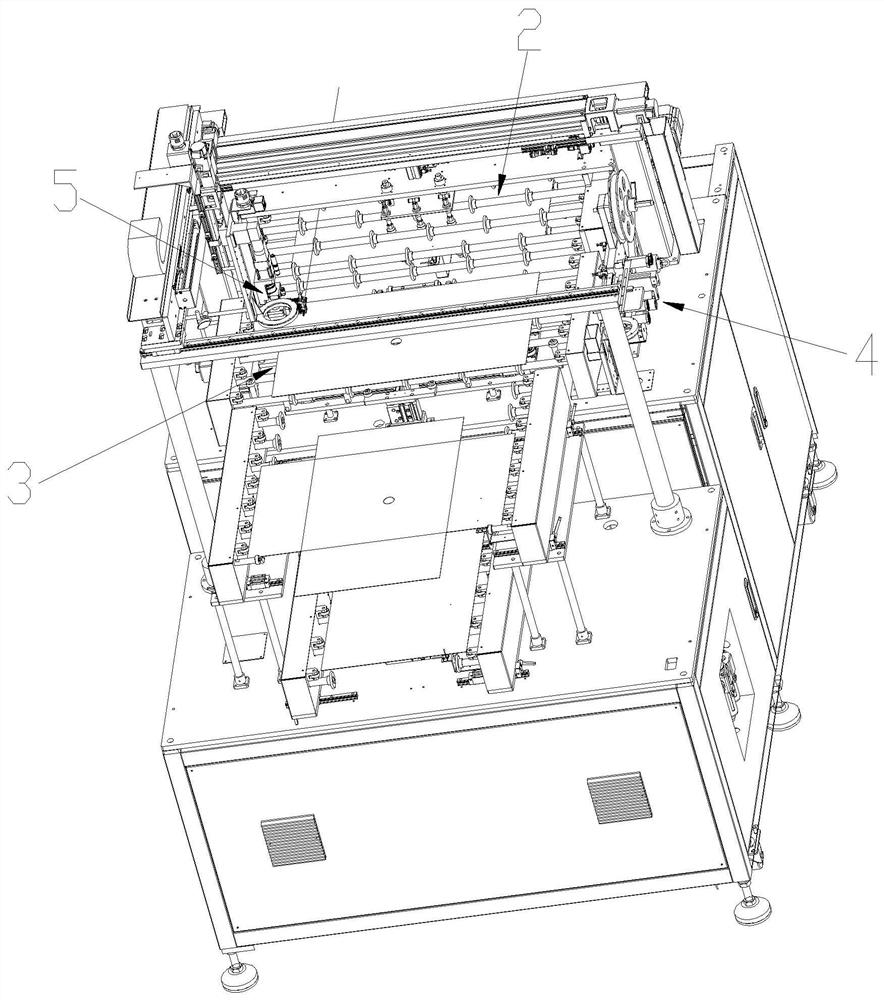

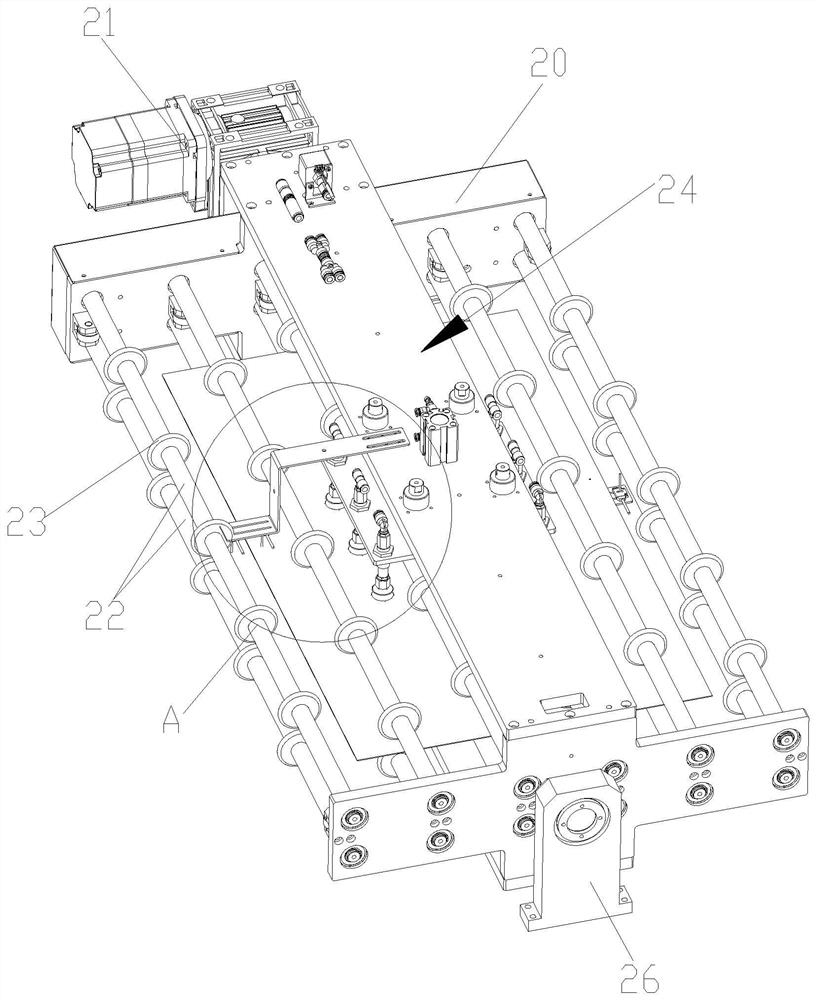

[0055] Please refer to the attached Figure 1-2 , a large glass partial film laminating machine according to the present invention includes a glass rotating device 2 arranged on the frame 1, which is used to rotate the glass delivered by the preceding equipment by 360°, so as to realize the turning of the glass. surface operation; the glass clamping and positioning mechanism 3 is set on the right side of the glass rotating device 2, and is used for clamping and positioning the rotated glass; the film feeding mechanism 4 is set on the glass clamping and positioning mechanism One side of 3 is used to provide the film to be pasted; the film pasting mechanism 5 is located above the glass clamping and positioning mechanism 3, and is used to attach the film to be pasted provided by the film feeding mechanism 4 to the glass; the finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com