Peanut roasting production line

A production line and roasting technology, applied in packaging, large containers, conveyor objects, etc., can solve the problems of peanut coat damage, shedding, loss of peanut nutrients, etc., and achieve the effect of reducing shedding, reducing continuity and ensuring integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

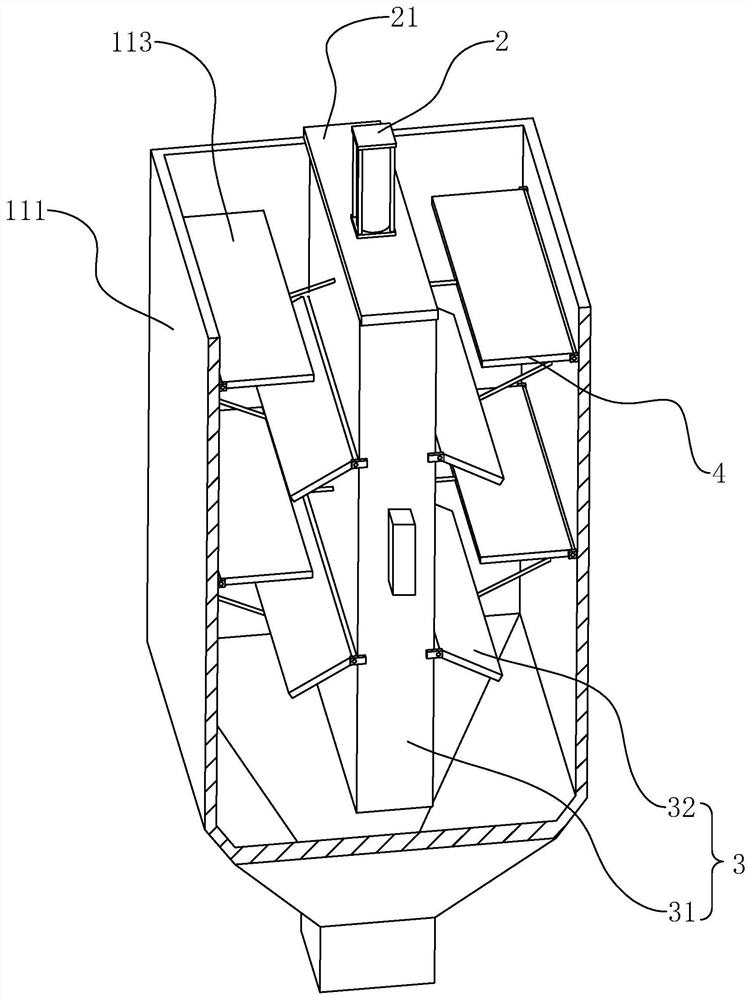

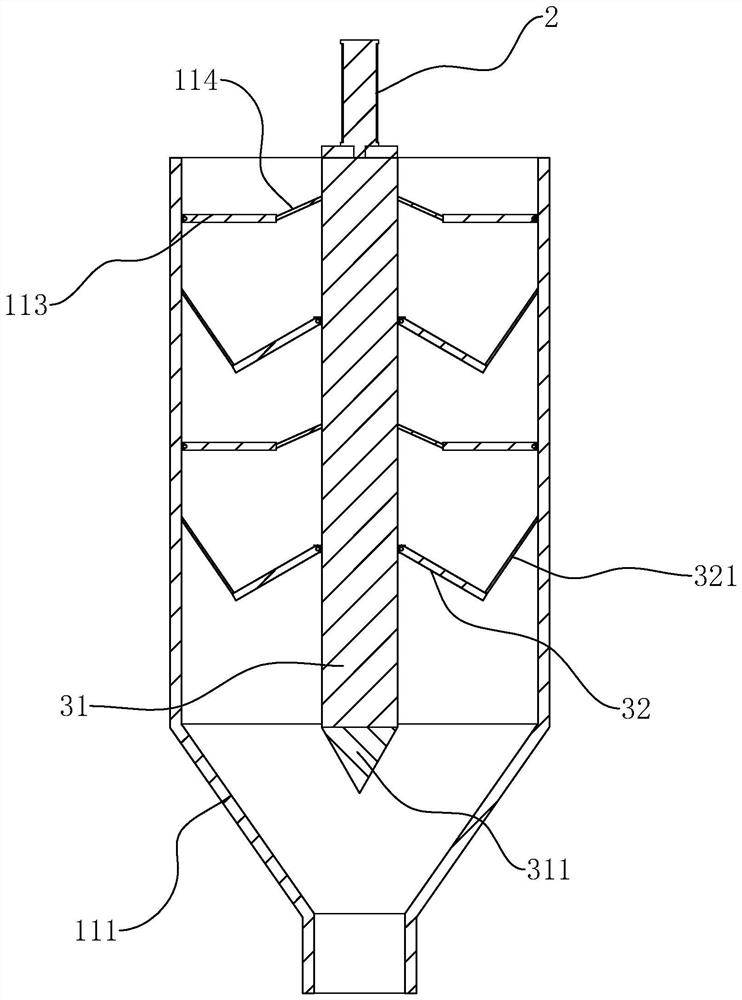

[0031] The following is attached Figure 1-3 The application is described in further detail.

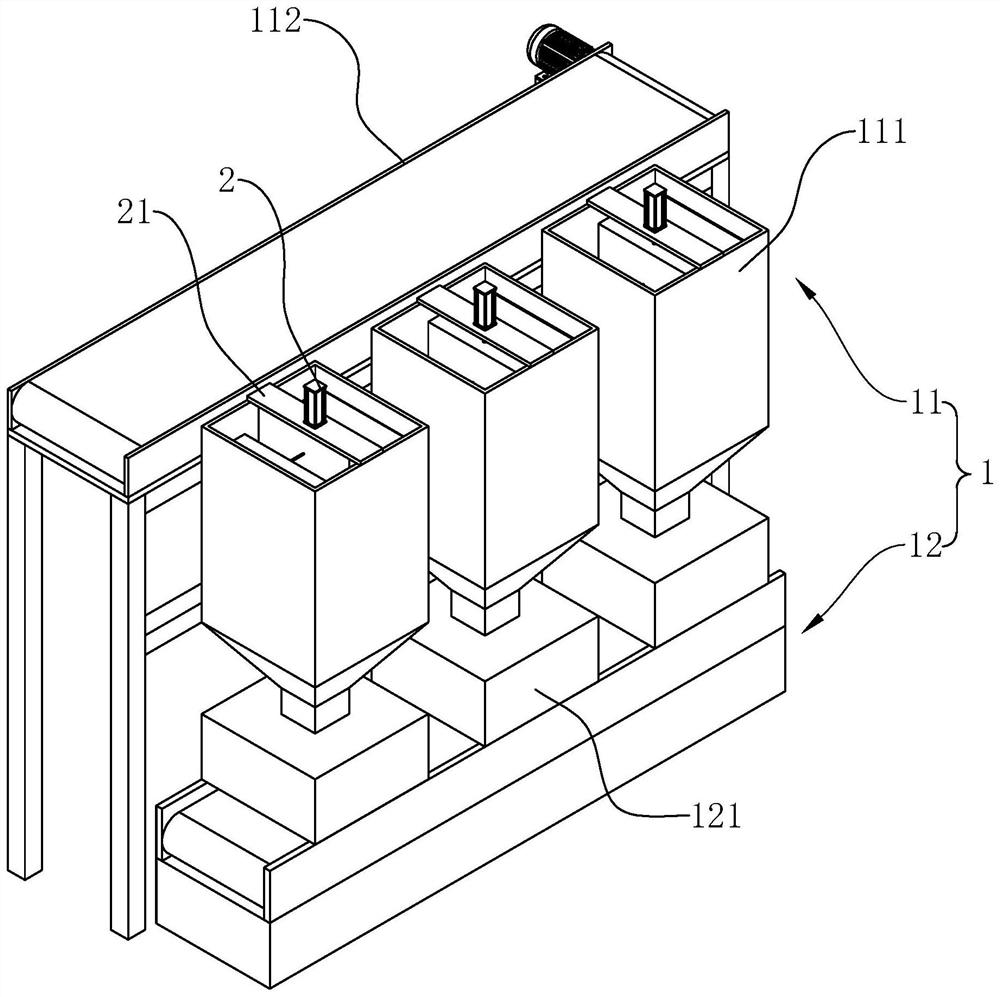

[0032] The embodiment of the present application discloses a peanut roasting production line. refer to figure 1 The peanut roasting production line includes a machine body 1. The machine body 1 includes a feeding device 11 and a roasting device 12 arranged in sequence according to the roasted peanut production process. The feeding device 11 is used to temporarily store raw peanuts and transmit raw peanuts to the roasting device 12. The roasting device 12 is used for roasting raw peanuts to obtain cooked peanuts. The feeding device 11 includes three receiving bins 111 of the same size, and the three receiving bins are arranged side by side. The upper end of each receiving bin 111 is a hollow cuboid shape and has a feed inlet at its top. The lower end of the receiving bin 111 is gradually narrowed so that the inner diameter of the lower end of the receiving bin 111 gradually becomes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com