Optical cable based on high flame retardance and high light transmittance

A technology with high light transmittance and high flame retardancy, applied in the field of optical cables, it can solve the problems of damage or wear at the bending position, poor impact resistance, and easy damage to internal wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

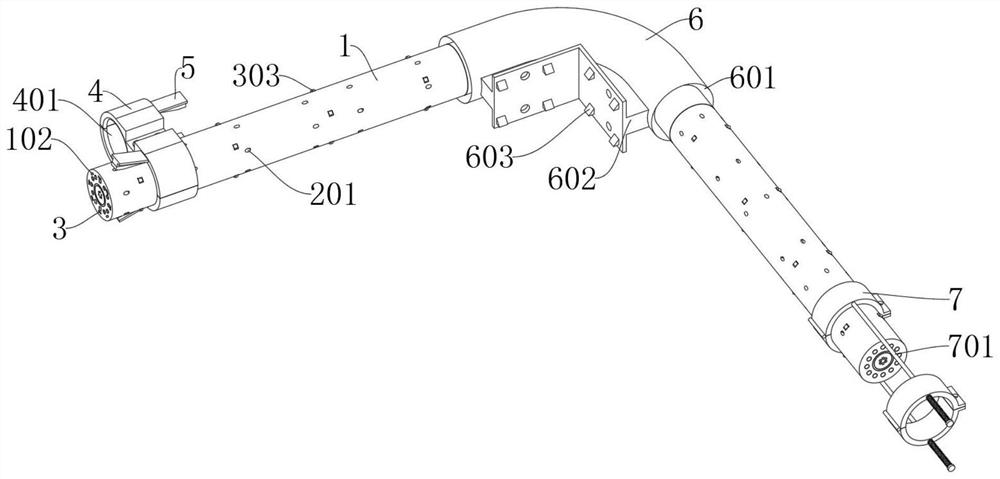

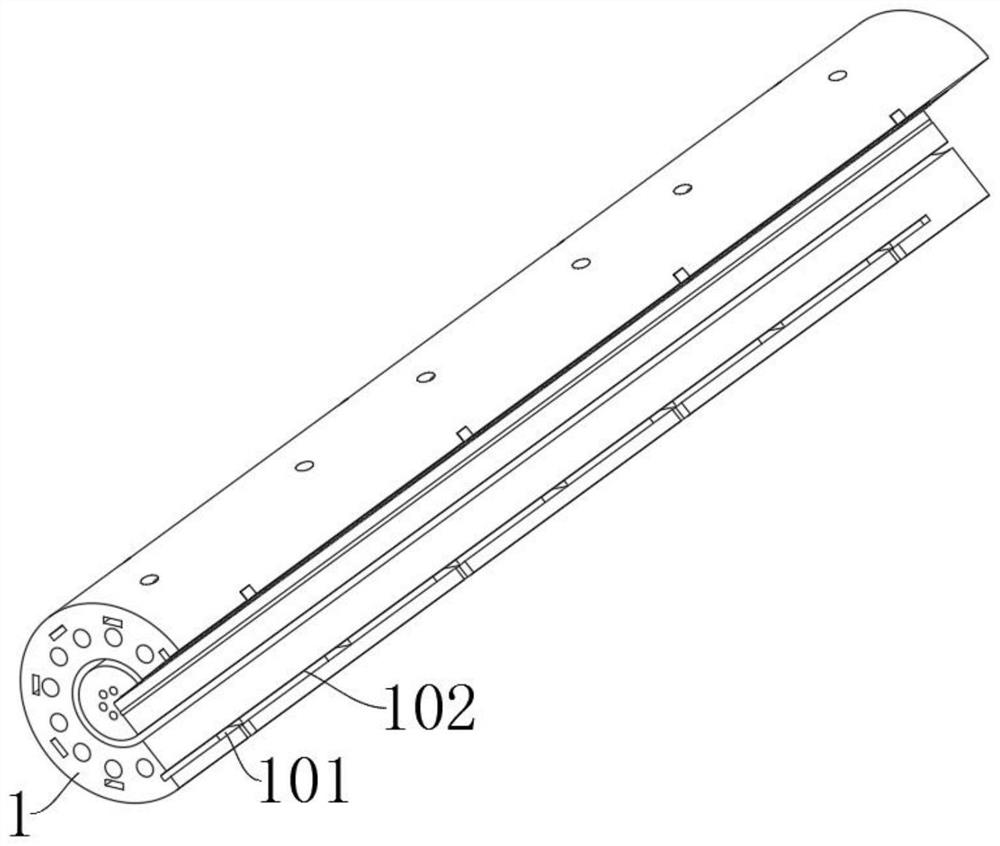

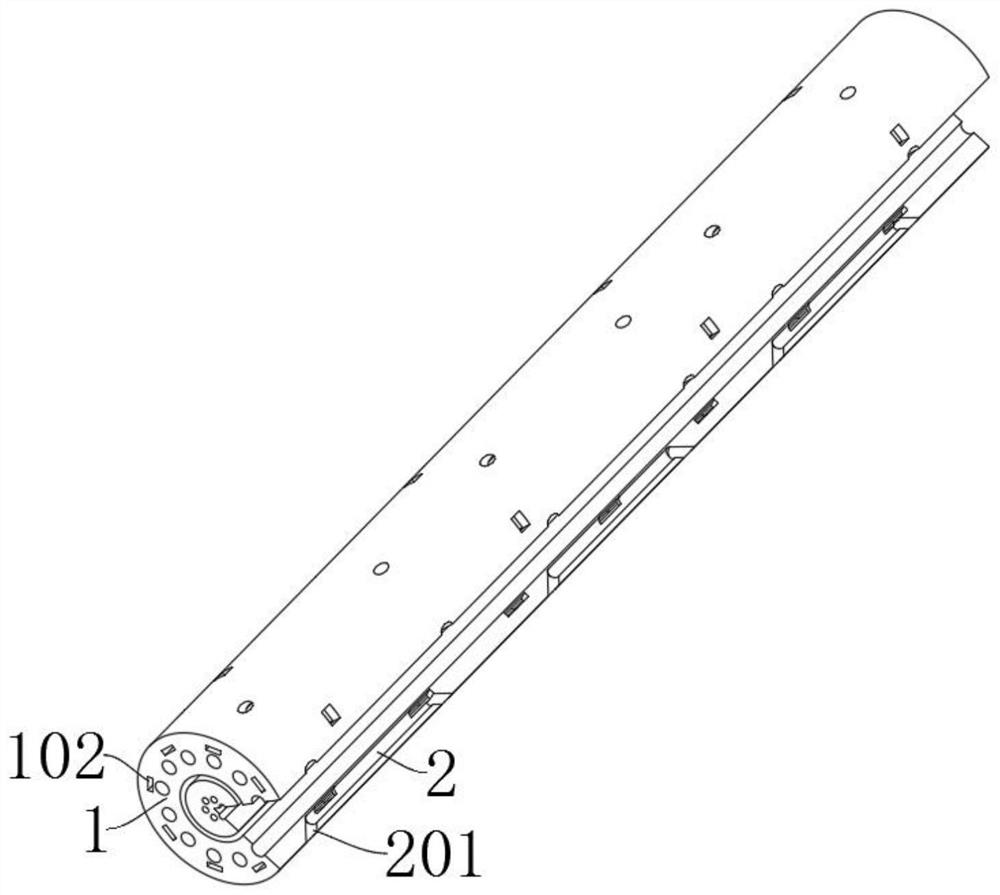

[0034] as attached figure 1 to the attached Figure 8 shown:

[0035] The present invention provides an optical cable based on high flame retardancy and high light transmittance, comprising a main body 1, a heat dissipation groove 2, a support member 3, a connecting head 4, a top block 5, a protective member 6 and a connecting ring 7; the main body 1 is the optical cable body, and The inside of the main body 1 is fixedly installed with wires; the heat dissipation groove 2 is arranged on the outside of the main body 1, and the heat dissipation grooves 2 are arranged in a ring; The inner end of the top block 5 is installed in the interior of the fixing groove 401 by embedding, and the rectangular block at the rear end of the top block 5 is embedded and installed in the limiting grooves on both sides of the guide groove 402; The outside of the main body 1 and the inside of the connecting ring 7 is fixedly connected to the outside of the main body 1 .

[0036] The supporting memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com