PID parameter setting method based on step response characteristic data of controlled object

A step-response, controlled object technology, applied in electric controllers, controllers with specific characteristics, etc., can solve problems such as inability to tune PID parameters online

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

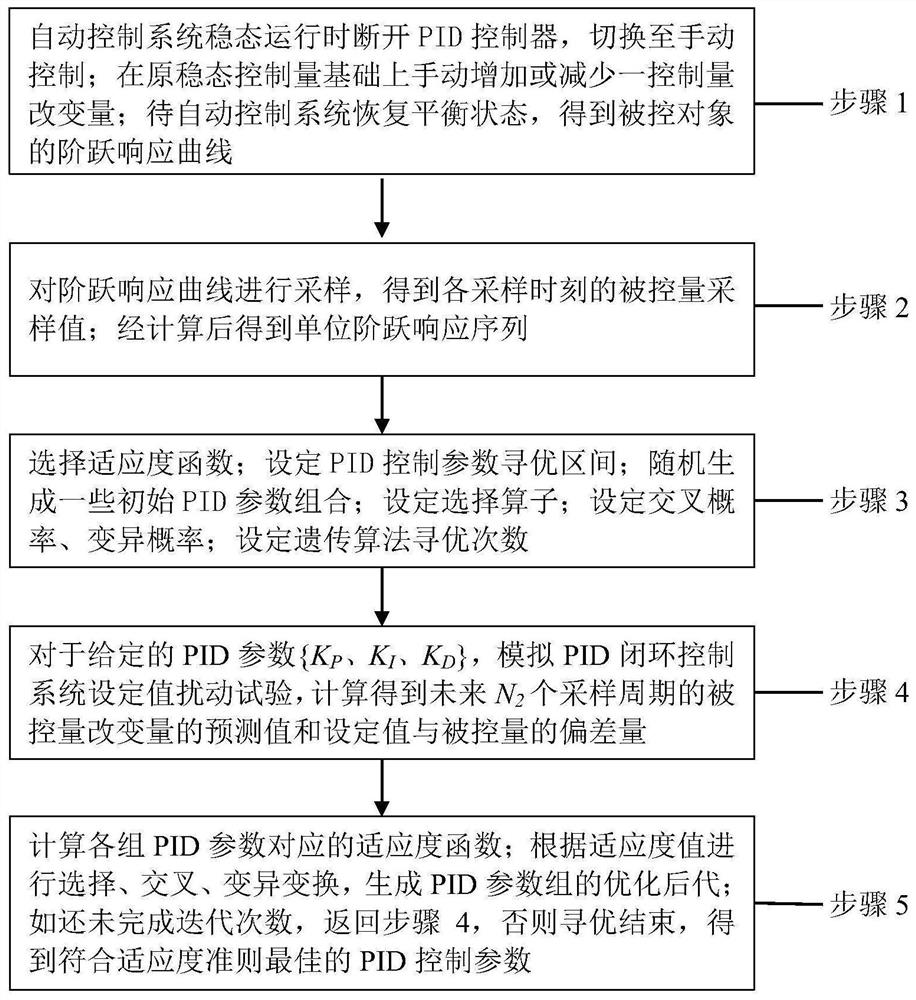

[0048] Such as figure 1 , in a specific embodiment of the present invention, a schematic flowchart of a PID parameter tuning method based on the step response characteristic data of the controlled object is shown.

[0049] A kind of PID parameter tuning method based on controlled object step response characteristic data, it comprises the following steps:

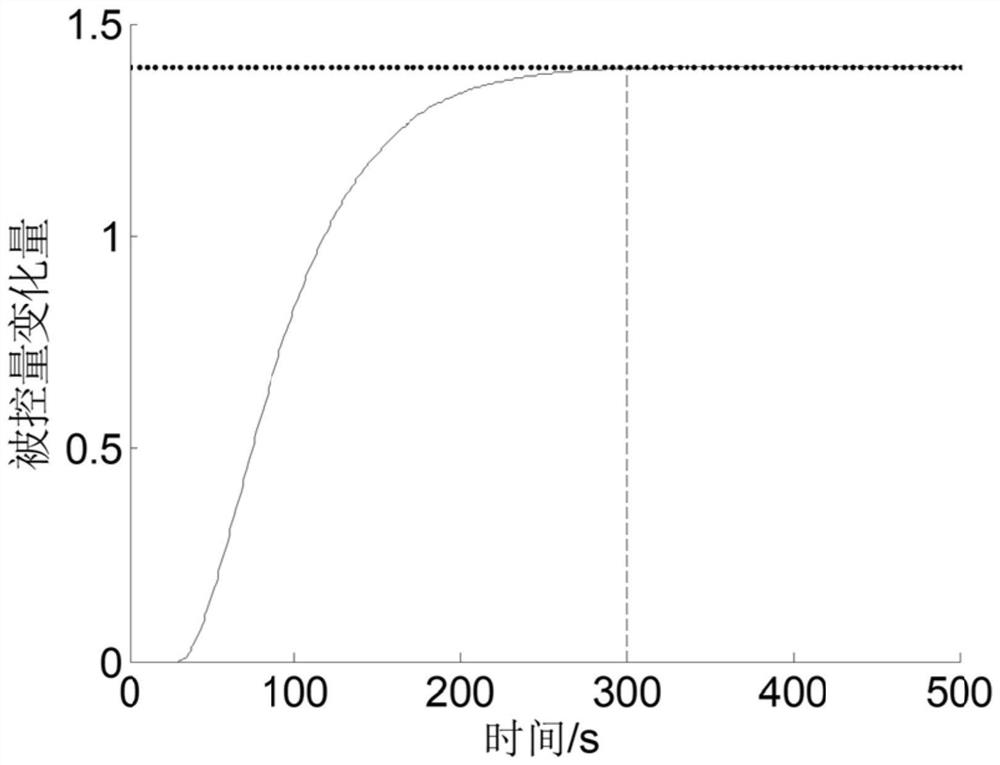

[0050] Step 1. When the automatic control system of the self-balancing controlled object is running in a steady state, disconnect the PID controller, and switch the automatic control system from the automatic control state to the manual control state; 0 Manually increase or decrease the control variable change u of a certain magnitude on the basis of ; wait for the automatic control system to return to the equilibrium state, and obtain the step response characteristic curve of the controlled self-balancing object.

[0051] Step 2, for the step response characteristic curve obtained in step 1, sample according to a certain s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com