Mold structure for molding glass insert

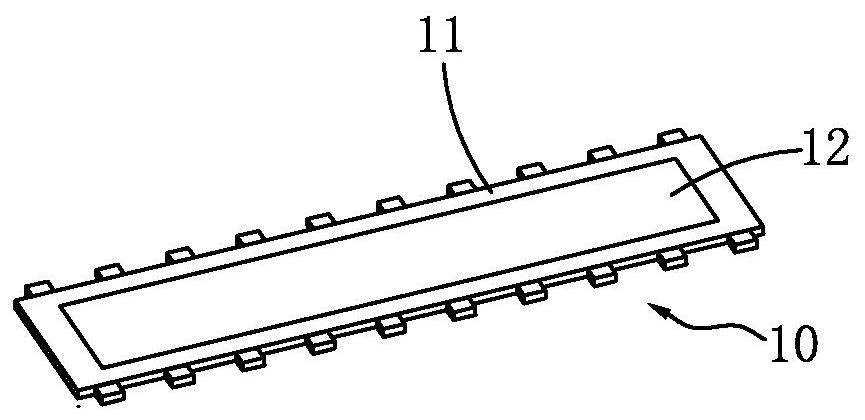

A technology of insert molding and glass, applied in the direction of coating, etc., can solve the problems of burrs on the product 10, crushing of the glass 11, crushing of the glass 11, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a further understanding of the purpose, technical effect and technical means of the present invention, the detailed description is as follows in conjunction with the accompanying drawings.

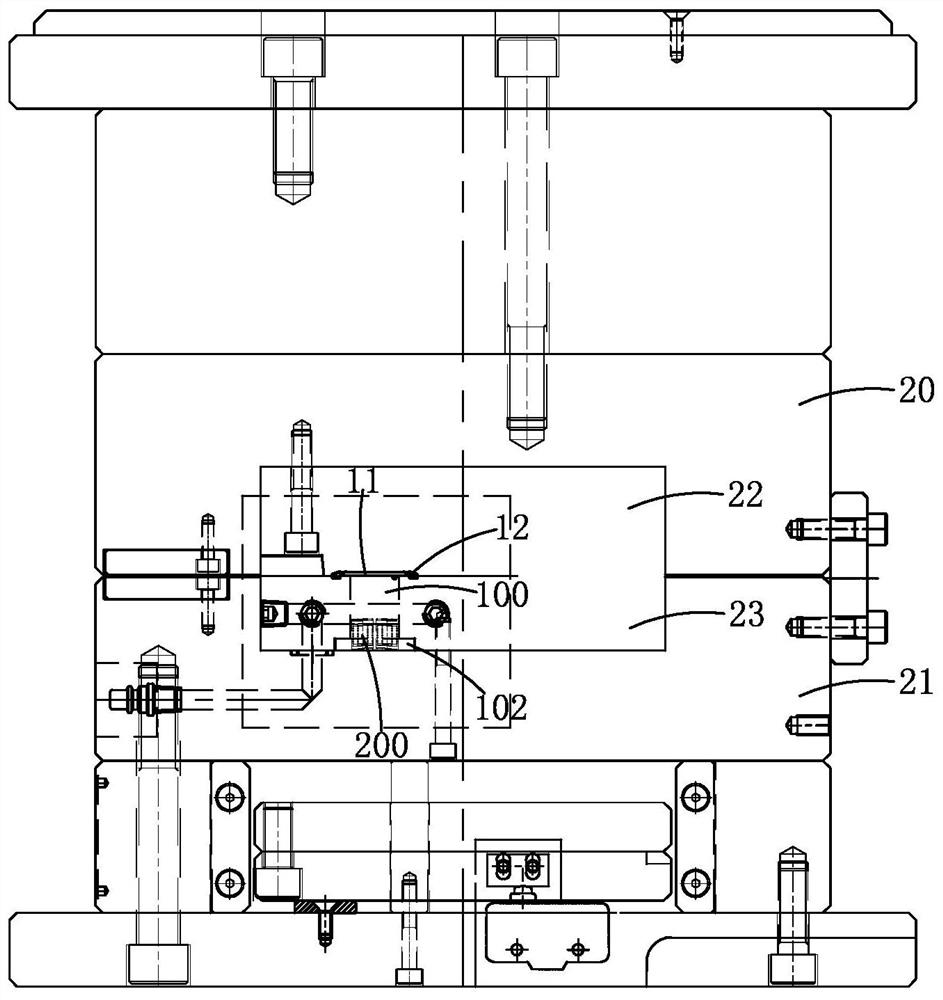

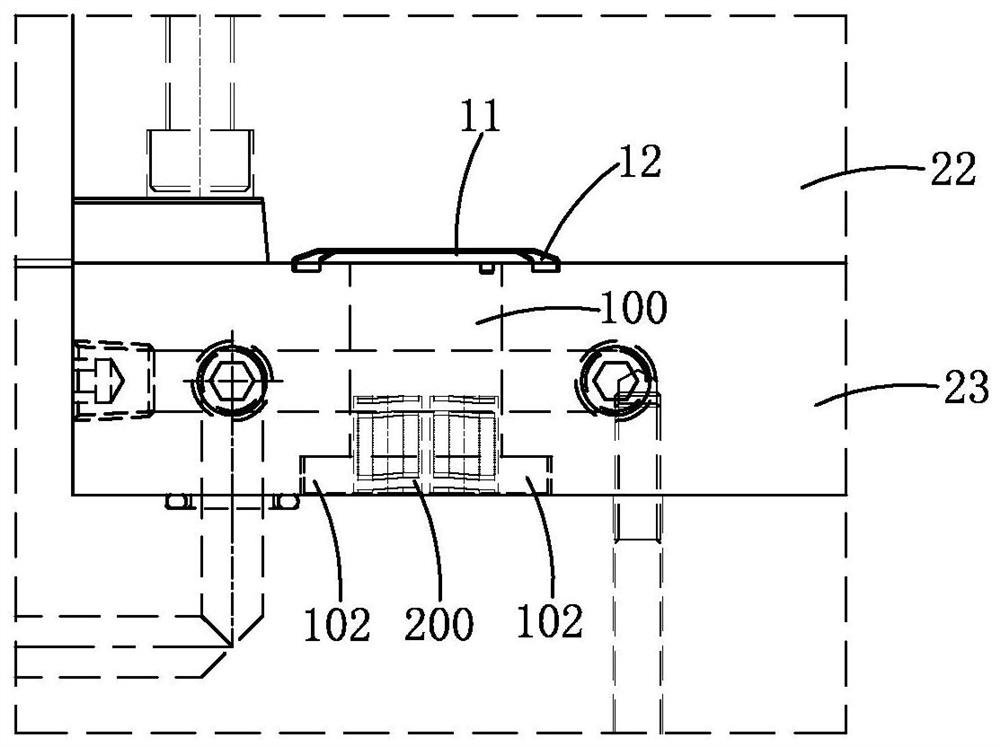

[0024] see Figure 2 to Figure 5 shown, where figure 2 A schematic diagram of a mold structure for glass insert molding of the present invention is depicted, image 3 painted figure 2 A partial enlargement of the Figure 4 It shows a schematic view of the floating insert in the mold structure of the glass insert molding of the present invention, Figure 5 Another schematic view of the floating insert in the mold structure for glass insert molding of the present invention is shown.

[0025] The mold structure for glass insert molding of the present invention includes a male mold 21, a female template 20, a cavity formed by a male mold core 23 and a female mold core 22, the cavity is used for forming a product 10, and the glass 11 is embedded In the cavity, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com