A main structure of plate and pole satellite

A technology of the main structure of a satellite, plate and rod type, applied in the field of spacecraft structure, can solve the problems of low local strength of the main load-bearing structure, low space utilization rate of the load-bearing cylinder, and not suitable for distributed loads, etc., so as to facilitate equipment layout, Overcome the effect of weak carrying capacity and easy assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the accompanying drawings and examples.

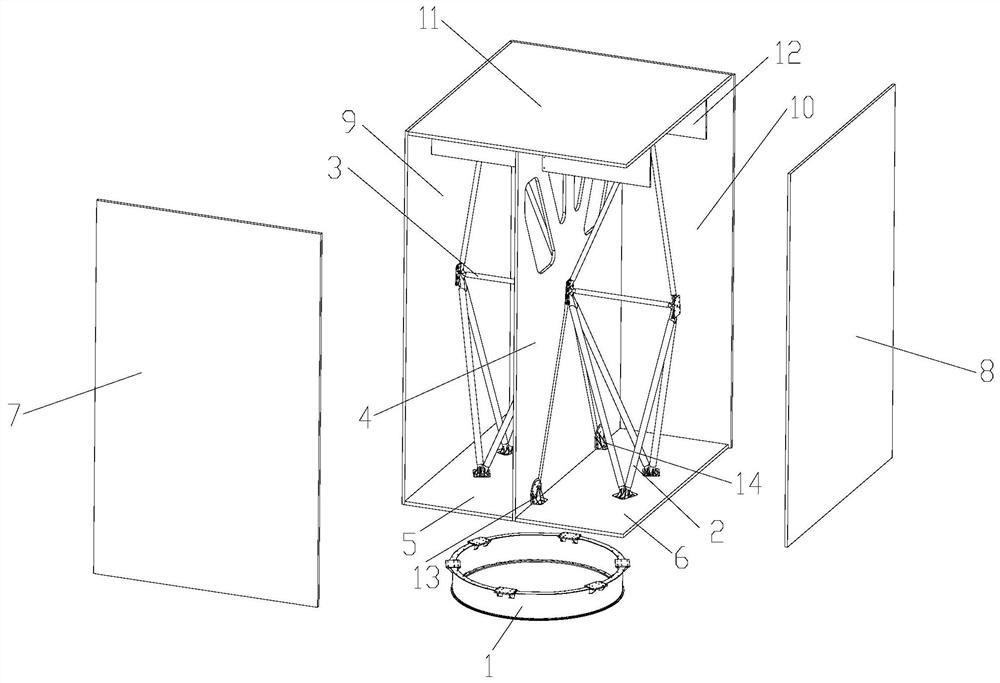

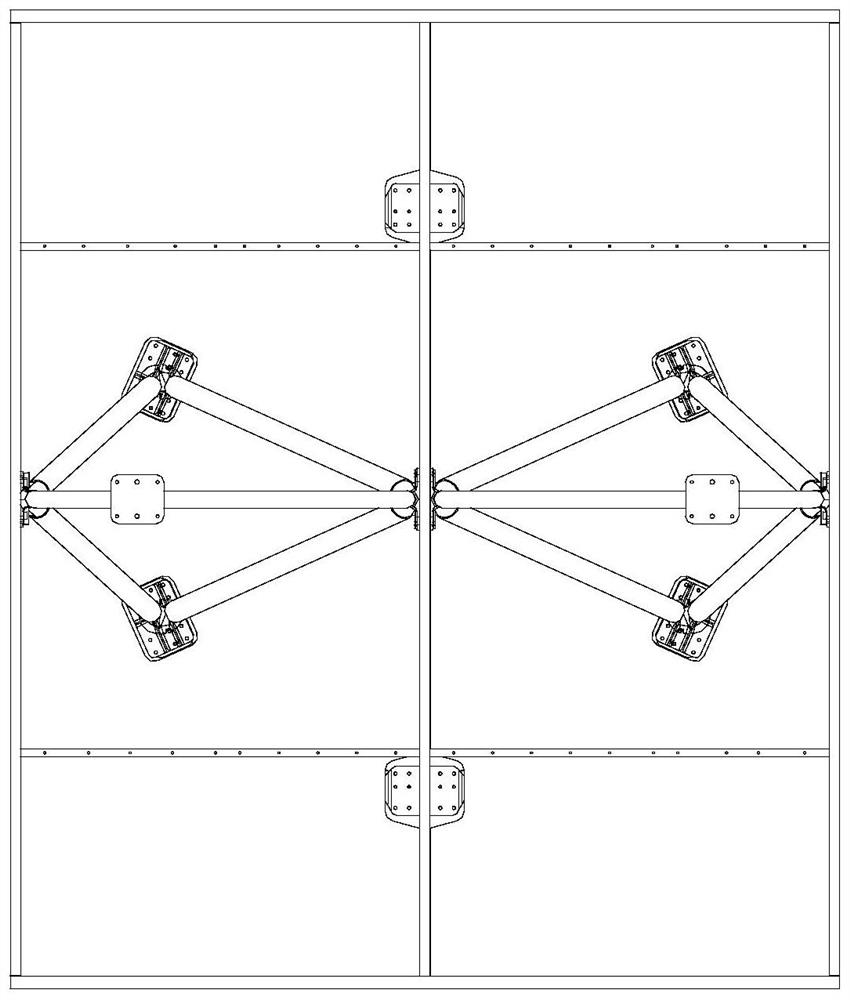

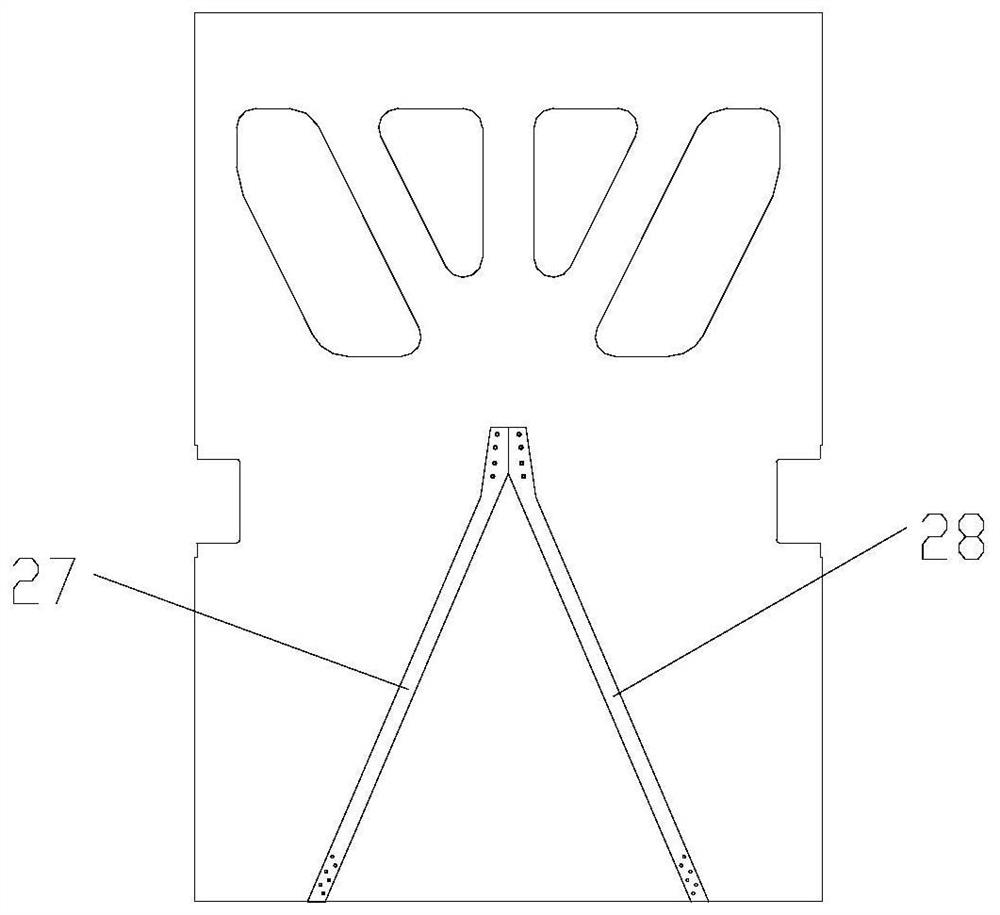

[0041]This embodiment provides a main structure of plate and rod type satellite, see attached Figure 1-2 , including: docking ring 1, main load-bearing partition 4, first rod system 2, second rod system 3, first back floor 5, second back floor 6, opposite floor 11 and four structural plates;

[0042] The docking ring 1 is an integral annular metal frame, and the upper end surface of the docking ring 1 is provided with six main load-bearing connecting flanges uniformly distributed along its circumference, and the lower end surface is a 1194A standard interface for docking with an external carrying interface ;

[0043] The four structural plates are respectively the first structural plate 7, the second structural plate 8, the third structural plate 9 and the fourth structural plate 10; the first structural plate 7, the second structural plate 8, the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com