Dyeing device and cloth dyeing method

A technology of dyeing device and dyeing method, which is applied to the processing of textile materials, continuous processing of textile materials, and processing of textile material carriers, etc., and can solve problems such as differences in dyeing results and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

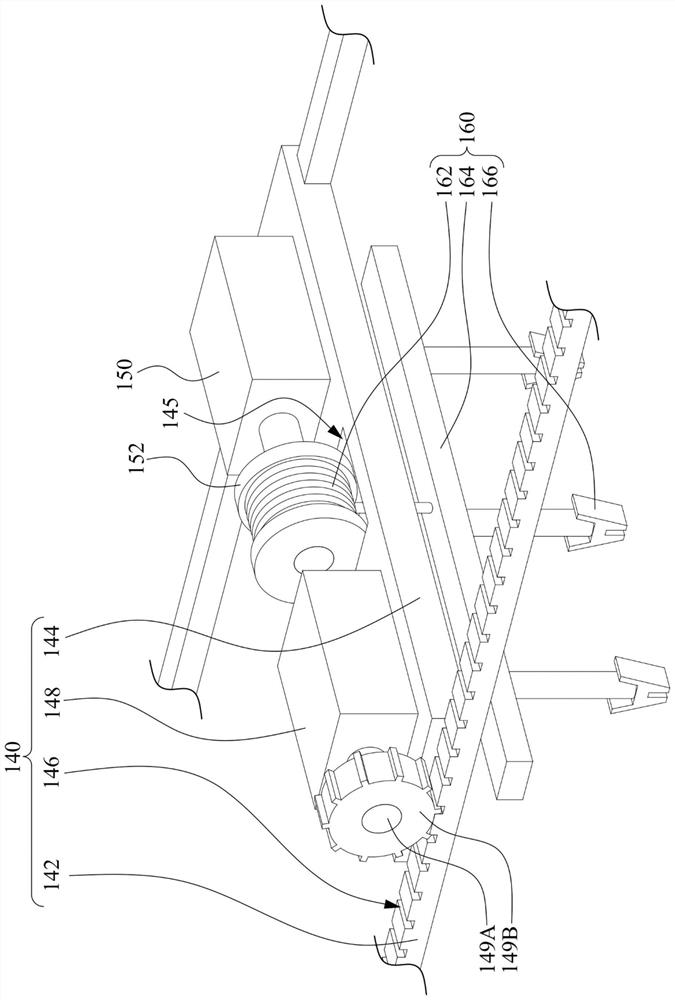

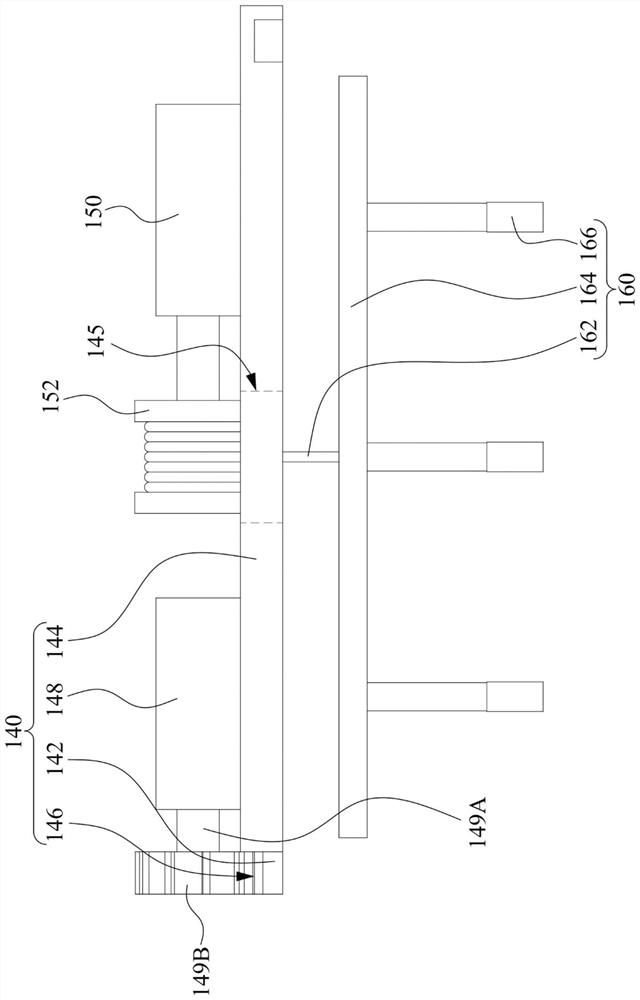

[0056] Embodiments of the present disclosure will be described below with reference to the accompanying drawings. For the sake of clarity, many practical details will be described together in the following description. However, it should be understood that these practical details should not be used to limit the present disclosure. That is, in some implementations of the present disclosure, these practical details are unnecessary. In addition, for the sake of simplifying the drawings, some known and conventional structures and elements will be shown in a simple and schematic manner in the drawings.

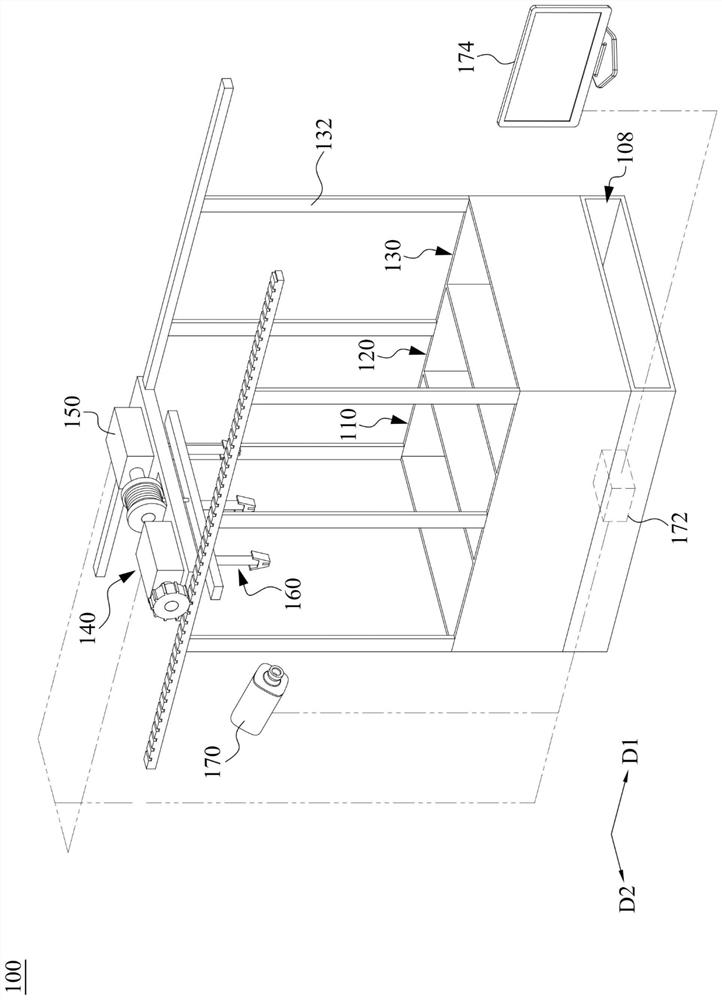

[0057] The dyeing device disclosed in the present disclosure can dye the cloth, capture images of the cloth during the dyeing process and record the lifting speed of the cloth, so as to collect relevant data of the cloth during the dyeing process. By collecting these relevant data, each dyeing process can output a set of test data, and when the database is established through mult...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap