Access hole design structure integrated on suspended ceiling plate and access hole mounting method

A technology for designing structures and ceiling panels, applied in the direction of ceilings, building components, building structures, etc., can solve the problems of difficult installation process, easy access to maintenance operations, cumbersome structure of access openings, etc., to simplify installation operations and structural design. Clever, avoid the effect of the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

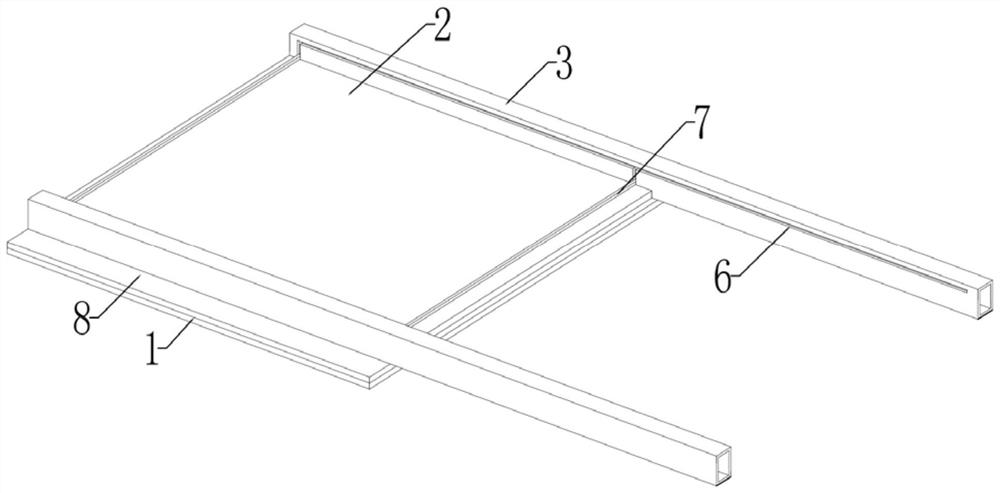

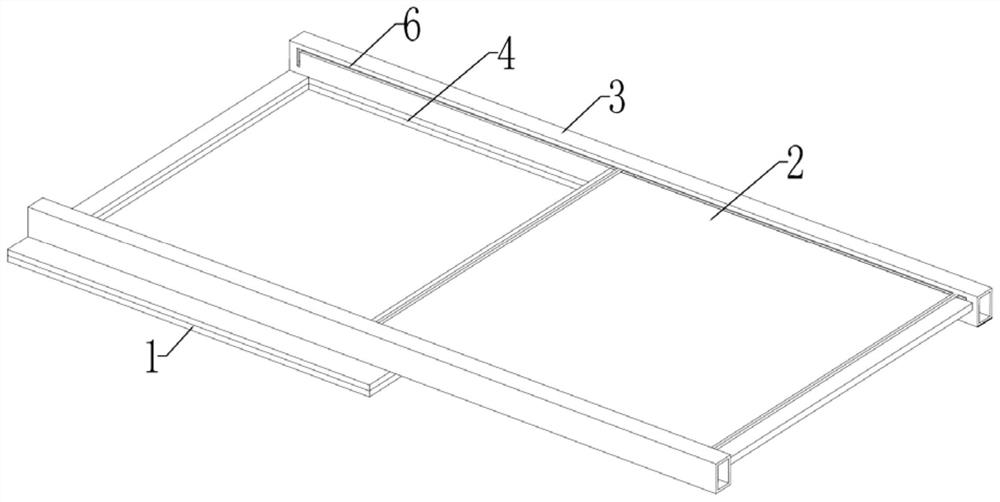

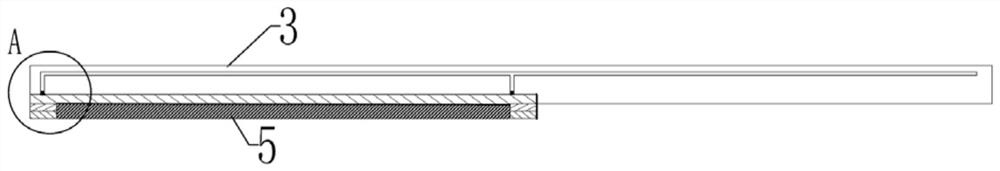

[0035] see Figure 1 to Figure 8 , the present embodiment provides a design structure of the inspection port integrated in the ceiling plate, wherein firstly, the first ceiling plate 1, the sealing plate 2 and the square tube 3 are set, the first ceiling plate 1 is a rectangular plate, and the square tube 3 is The two are fixedly connected to the first ceiling plate 1, the two square tubes 3 are parallel to each other, the sealing plate 2 is arranged on the first ceiling plate 1, and the two ends of the sealing plate 2 are attached to the two square tubes 3 respectively, An inspection hole 4 is opened on the first ceiling plate 1, and the inspection hole 4 is a rectangular through hole. The bottom surface of the sealing plate 2 is provided with a boss 5 adapted to the shape of the inspection hole 4, and the boss 5 is clamped in the inspection hole 4. The side wall of the square tube 3 is provided with a chute 6, and the top surface of the sealing plate 2 is provided with a plu...

Embodiment 2

[0043] see Figure 1 to Figure 8 , the figure shows a design structure of an inspection port integrated into the ceiling plate provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: chute 6 includes a vertical slideway 61 and a horizontal slideway 62, and the vertical slideway 61 and the horizontal slideway 62 communicate with each other.

[0044] Specifically, see Figure 1 to Figure 8 , two slide bars 7 are snapped into two vertical slideways 61 respectively.

[0045] Specifically, see Figure 1 to Figure 8 , the length of the vertical slideway 61 is greater than the height of the boss 5 .

[0046] Specifically, see Figure 1 to Figure 8 , the length of the transverse slideway 62 is twice the width of the first ceiling board 1 .

[0047] Push the cover plate 2 upwards, the slide bar 7 slides along the vertical slideway 61, and the two slide bars 7 slide in ...

Embodiment 3

[0049] see Figure 1 to Figure 8 , the figure shows a design structure of the inspection port integrated in the ceiling plate provided by the third embodiment of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: square tube There is a gap 8 of a certain length between the side of 3 and the side of the first ceiling board 1 .

[0050] The square tube 3 is fixedly installed on the side wall of the keel, the conventional ceiling board is fixedly installed on the bottom surface of the keel, and the end of the conventional ceiling board is lapped under the keel, in order to make the first ceiling board 1 and the conventional The installation mode of the ceiling board is the same, and it is necessary to leave a gap 8 between the square pipe 3 and the side of the first ceiling board 1, so that the end of the first ceiling board 1 is overlapped under the keel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com