Quantitative feeding and crushing equipment for feed

A technology for crushing equipment and feed, applied in feed, grain processing, transportation and packaging, etc., can solve the problems of dangerous operation, inconvenient installation and disassembly, cumbersome operation, etc., to avoid disassembly and installation, facilitate disassembly and installation, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

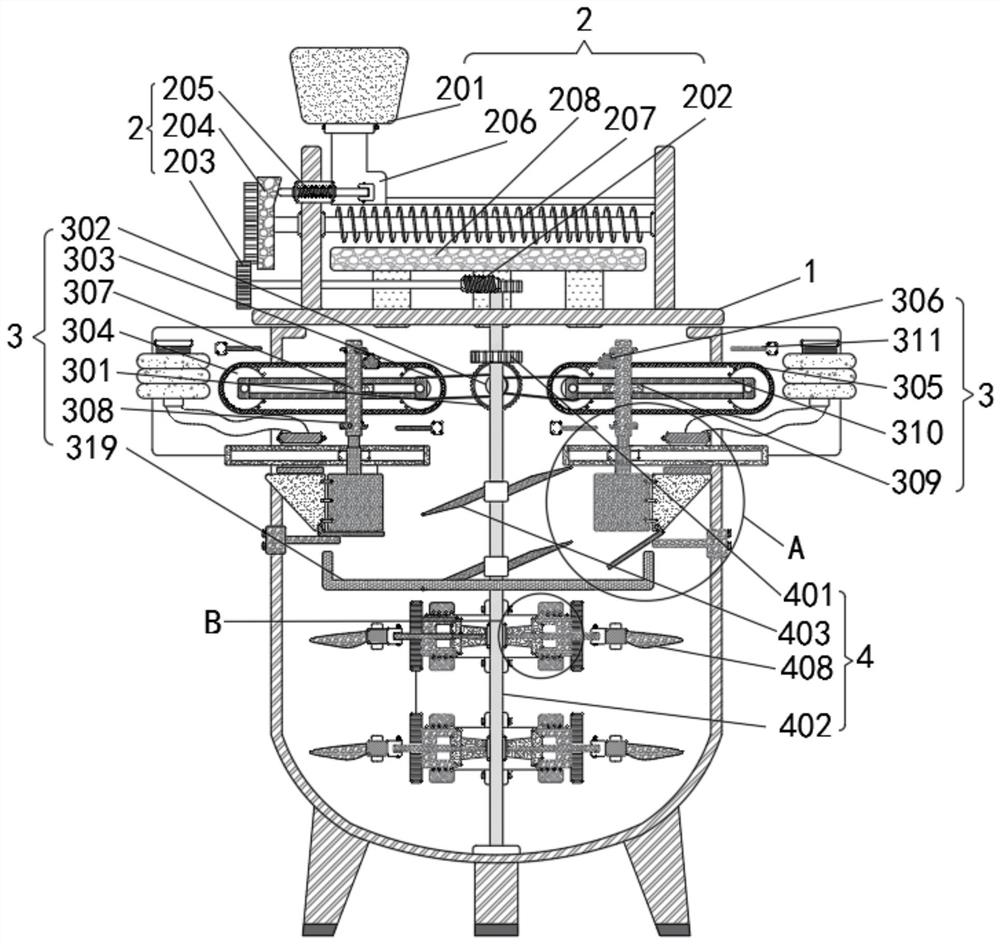

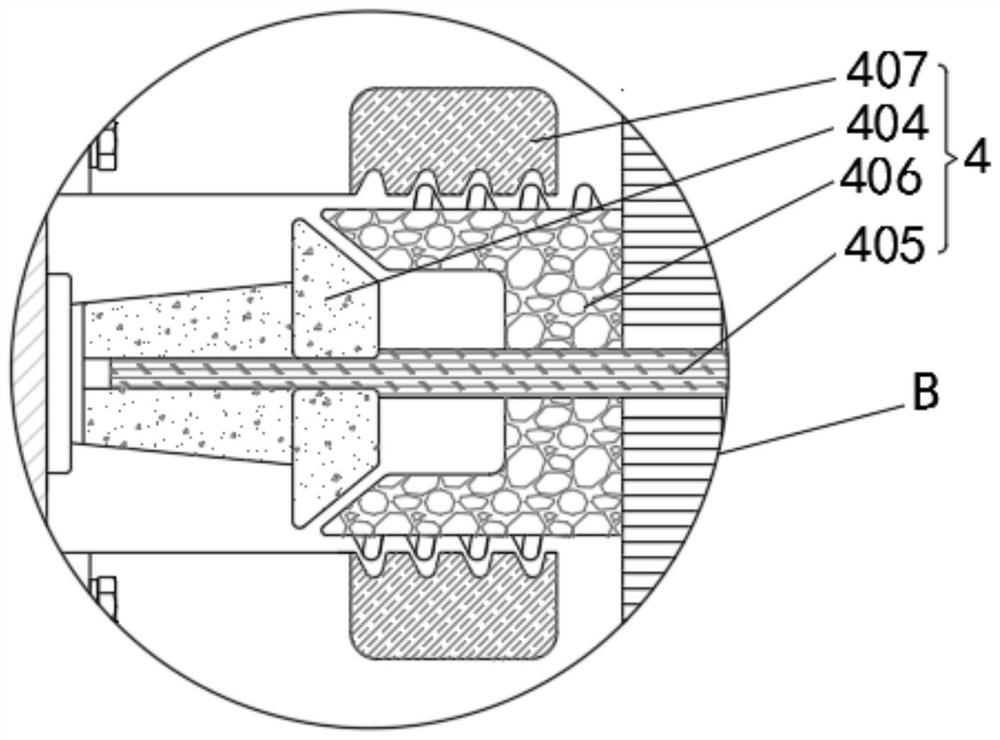

[0025] see figure 1 and figure 2 , a kind of crushing equipment for feeding quantitatively, comprising a whole shell 1, the outer wall of the upper end of the shell 1 is fixedly connected with a feeding device 2, the middle end of the shell 1 is fixedly connected with a proportioning device 3, and the lower end of the shell 1 is equipped with an easy-to-disassemble Stirring device4.

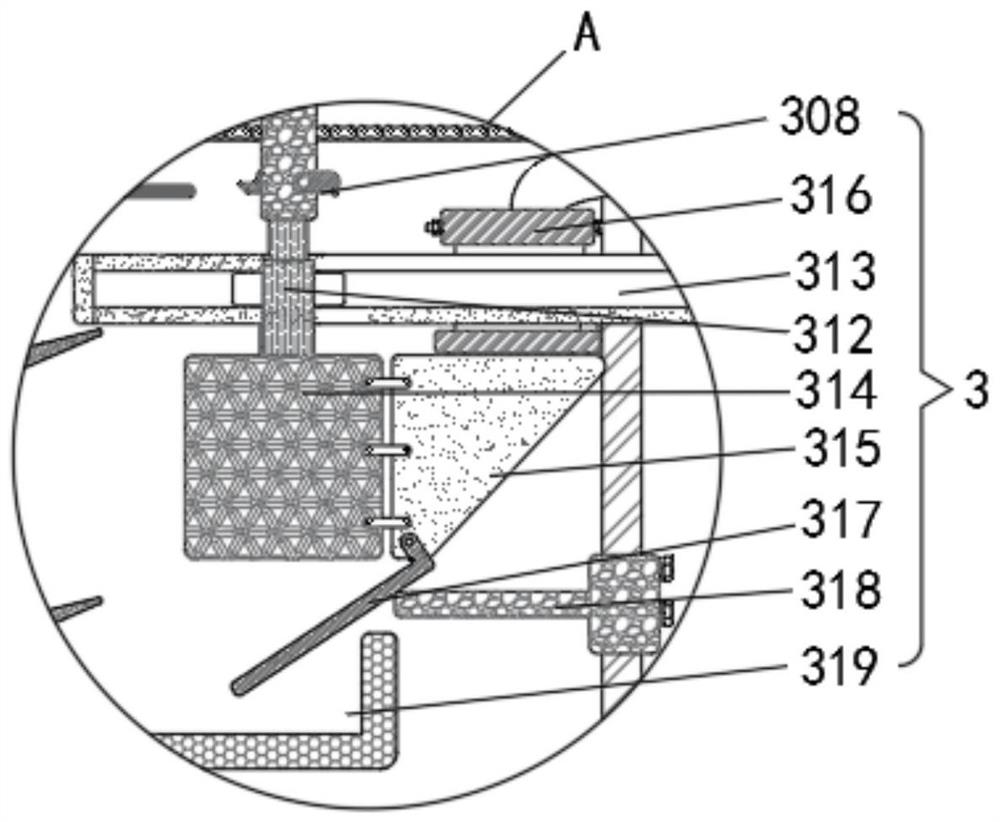

[0026] The middle end of the proportioning device 3 includes a main force gear 301, the front end of the main force gear 301 is fixedly connected with a double-headed pulley 302, and the double-headed pulley 302 is rotatably connected to a rubber belt 303, and the left end of the rubber belt 303 is rotatably connected to a runner 304, and the outer wall of the runner 304 is rotatably connected to Chain 305, the upper end of chain 305 is fixedly connected with power block 306, power block 306 left end is provided with linkage plate 307, the upper and lower ends of linkage plate 307 all rotate an...

Embodiment 2

[0029] see Figure 1-3 , a kind of crushing equipment for feeding quantitatively, comprising a whole shell 1, the outer wall of the upper end of the shell 1 is fixedly connected with a feeding device 2, the middle end of the shell 1 is fixedly connected with a proportioning device 3, and the lower end of the shell 1 is equipped with an easy-to-detachable Stirring device4.

[0030]Further, the middle end of the feeding device 2 is provided with a first threaded rod 202, the left end of the first threaded rod 202 is fixedly connected with a first gear 203, the upper end of the first gear 203 is connected to the crank gear turntable 204 in rotation, and the upper end of the crank gear turntable 204 is connected to the crank wheel in rotation. Spring bar 205, spring bar 205, upper end is provided with feed cylinder 206, and the upper end of feed cylinder 206 is fixedly connected with storage funnel 201, and the right end of crank gear rotating disk 204 is fixedly connected with sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com