Pump body and double-screw pump

A screw and pump body technology, used in pumps, pump components, rotary piston pumps, etc., can solve the problems of small space volume, small space, screw pump power and supply liquid flow, etc., to reduce noise and increase volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

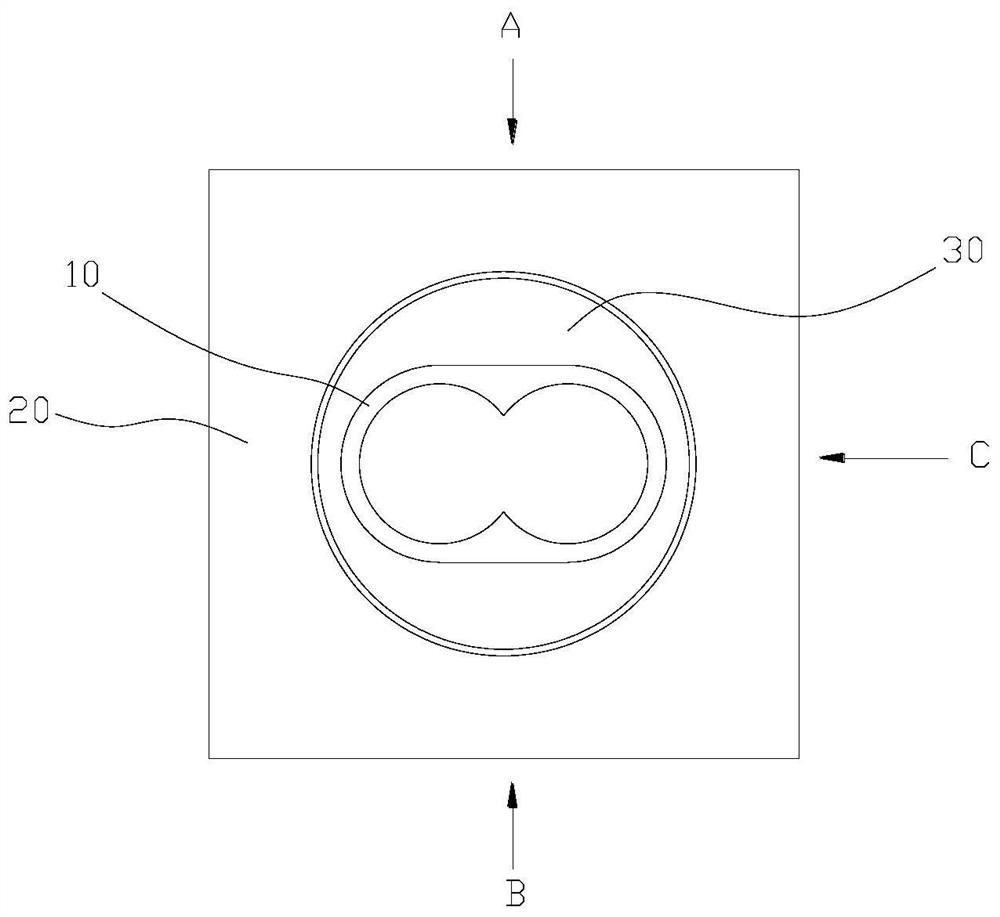

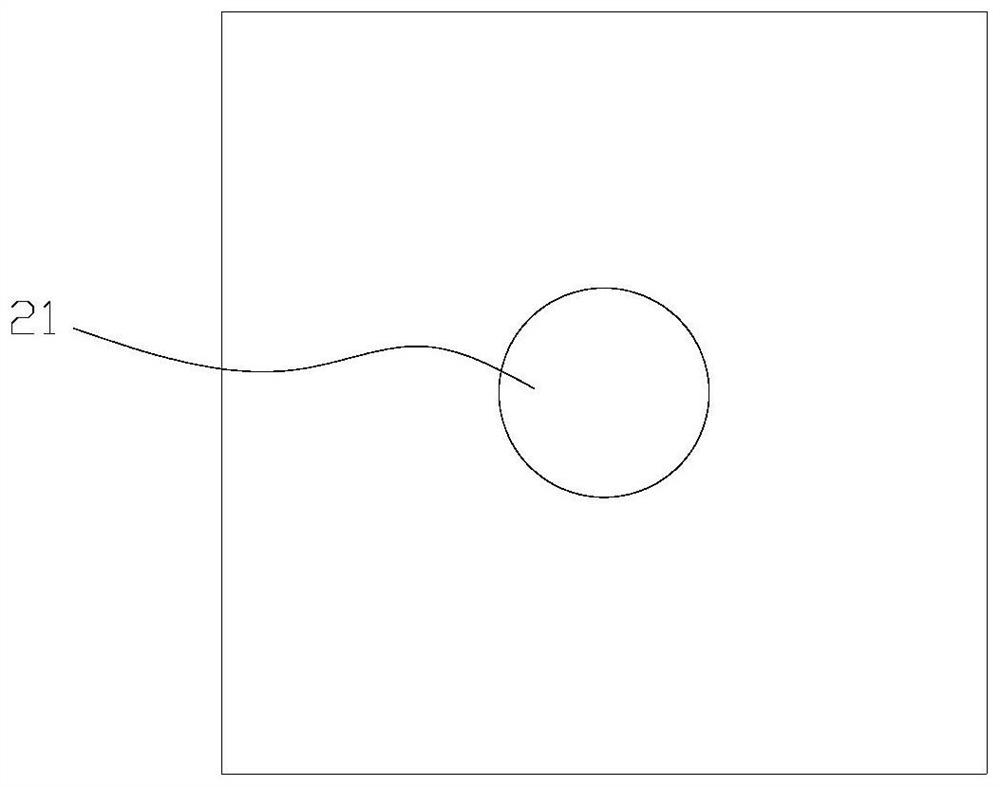

[0036] In this example, if Figure 1 to Figure 4 As shown, the liquid inlet 21 and the liquid outlet 22 are respectively provided on two opposite surfaces of the main body 20 , and the valve installation port 23 is provided on the surface adjacent to the surface where the liquid inlet 21 is located.

Embodiment 2

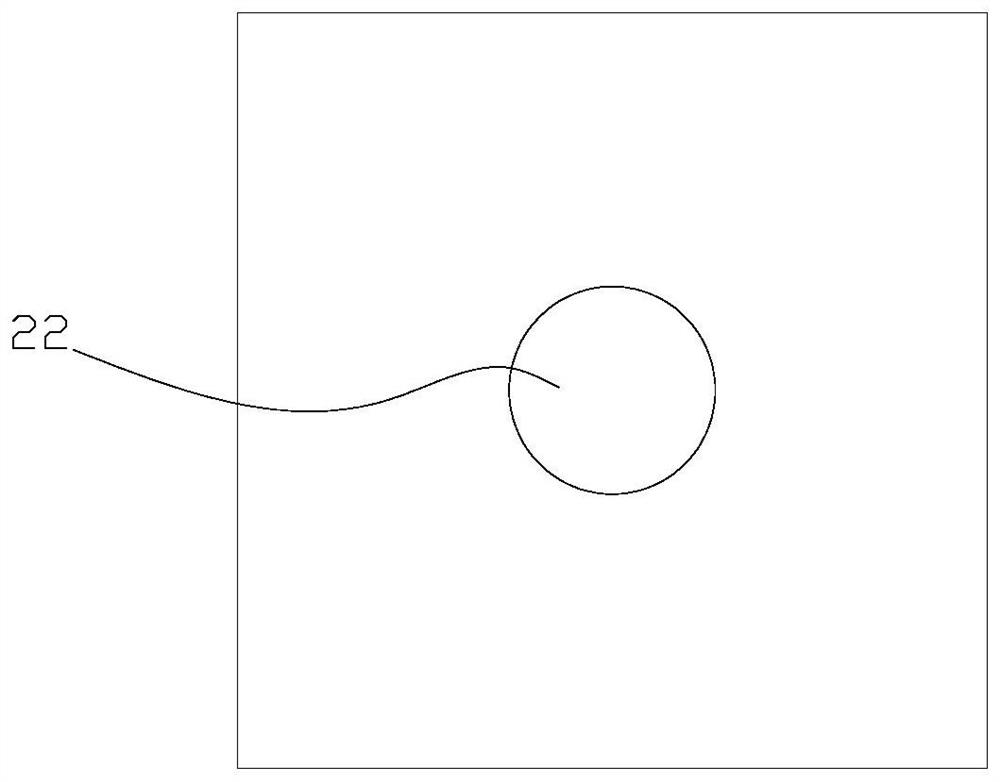

[0038] In this example, if Figure 5 to Figure 8 As shown, the liquid inlet 21 and the valve installation port 23 are opened on two opposite surfaces of the main body 20 respectively, and the liquid outlet 22 is opened on the surface adjacent to the surface where the liquid inlet 21 is located.

[0039] The advantages of the pump body and the twin-screw pump disclosed by the present invention are:

[0040] 1. By setting the inside of the main body 20 as a rectangular cavity 30, the volume in the cavity is increased, thereby increasing the "drinking" water volume of the cavity, and under the driving action of the two screws, sufficient liquid flow can be provided, and Effectively provides the power of the pump.

[0041] 2. The pump body with the above structure reduces the noise of pump operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com