State detection method and device for weighing sensors

A technology of state detection device and weighing sensor, which is applied in the direction of weighing indicating device, weighing temperature compensation device, measuring device, etc., can solve the problem of inability to accurately locate sensor faults, and achieve the effect of improving user satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

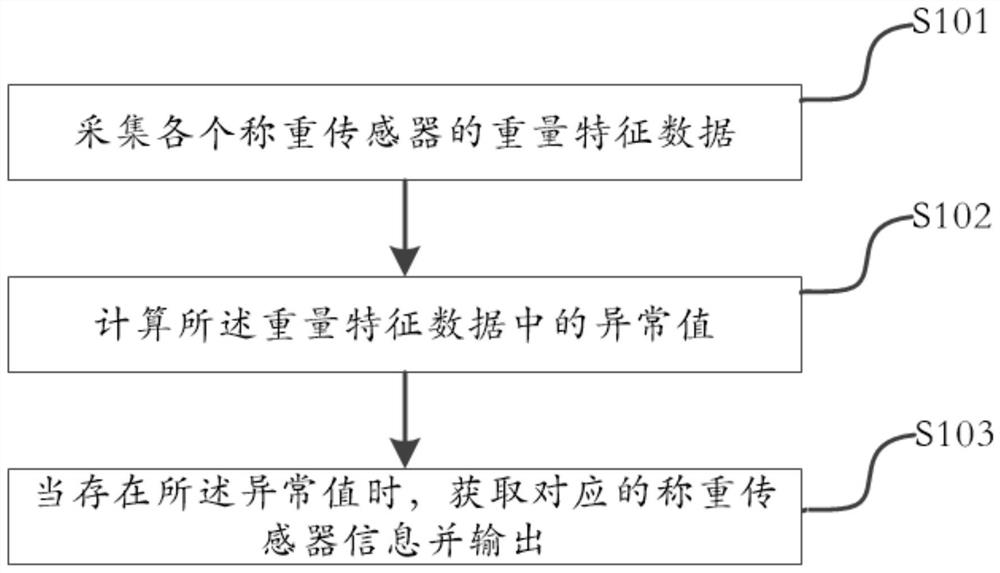

Embodiment 1

[0029] Platform scales are electronic weighing instruments between platform scales and truck scales. They are widely used in industrial production, commodity trading and daily life. The platform scale can include a plurality of, for example, multi-point weighing composed of four load cells, and the load cells are installed at corresponding weighing positions of the platform scale.

[0030] (1) Differential detection of zero weight

[0031] Before the platform scale is calibrated, the weighing platform needs to be leveled. If there is an uneven weighing platform, it will seriously affect the linearity and hysteresis of the weighing platform, resulting in inaccurate weighing. Therefore, when the weighing platform is empty, if it is detected that the outputs of the four sensors are relatively close, it indicates that the weighing platform has been leveled. When the weighing platform has been used for a period of time, or a sensor is displaced due to improper operation by the us...

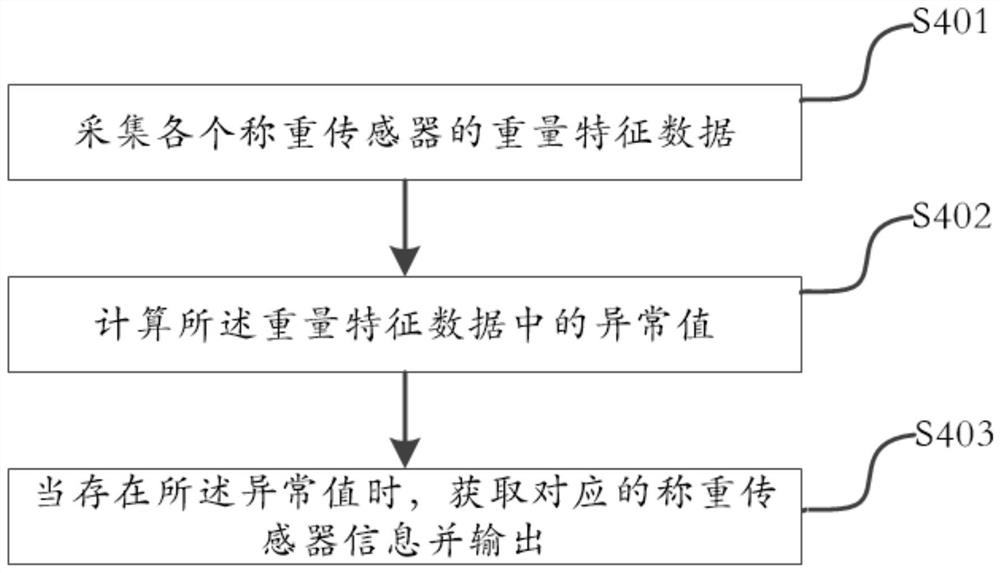

Embodiment 2

[0062] The tank system is widely used in industrial and agricultural production, and can include multiple, such as multi-point weighing composed of 4 load cells.

[0063] (1) Abnormal detection of zero weight data

[0064] When the tank system is calibrated, the zero output of each sensor is basically consistent to ensure the accuracy of the measurement. When the material tank is shifted on the weighing foundation, the output of a certain sensor will often be too large or too small, which will seriously affect the accuracy. A method for detecting the state of a load cell in this embodiment is applied to a material tank system, and the material tank system includes three load cells.

[0065] A method for detecting the state of a load cell in this embodiment is applied to a material tank system, including:

[0066] Step S401, collecting the weight characteristic data W of each load cell Mi .

[0067] Among them, M i represents the corresponding load cell, thus forming The...

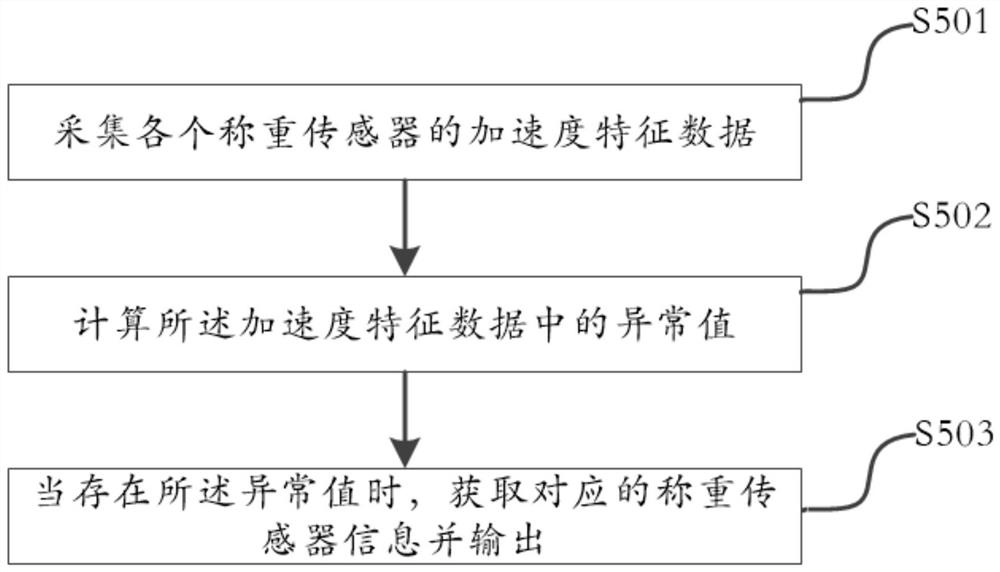

Embodiment 3

[0093] Multi-point weighing technology is also commonly used in vehicle scale systems. A vehicle scale system in this embodiment is composed of 8 load cells.

[0094] In vehicle scale applications, each load cell is equipped with a gas sensor for air tightness detection. By comparing the difference in gas concentration between sensors, the air tightness of one or several sensors can be judged. There is a problem.

[0095] A method for detecting the state of a load cell in this embodiment is applied to a vehicle scale system, including:

[0096] Step S701, collecting gas characteristic data of each weighing sensor

[0097] The vehicle scale system of this embodiment first collects the gas characteristic data of each weighing sensor Form gas characteristic data queue

[0098] Step S702, calculating abnormal values in the gas characteristic data.

[0099] In this embodiment, the most value detection algorithm is used to detect the difference between the weight feature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com