A device for peeling the sheath of waste electric cables

A technology for power cables and sheaths, which is applied in the field of waste power cable sheath peeling devices, can solve the problems of manpower consumption, and achieve the effect of simple operation and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

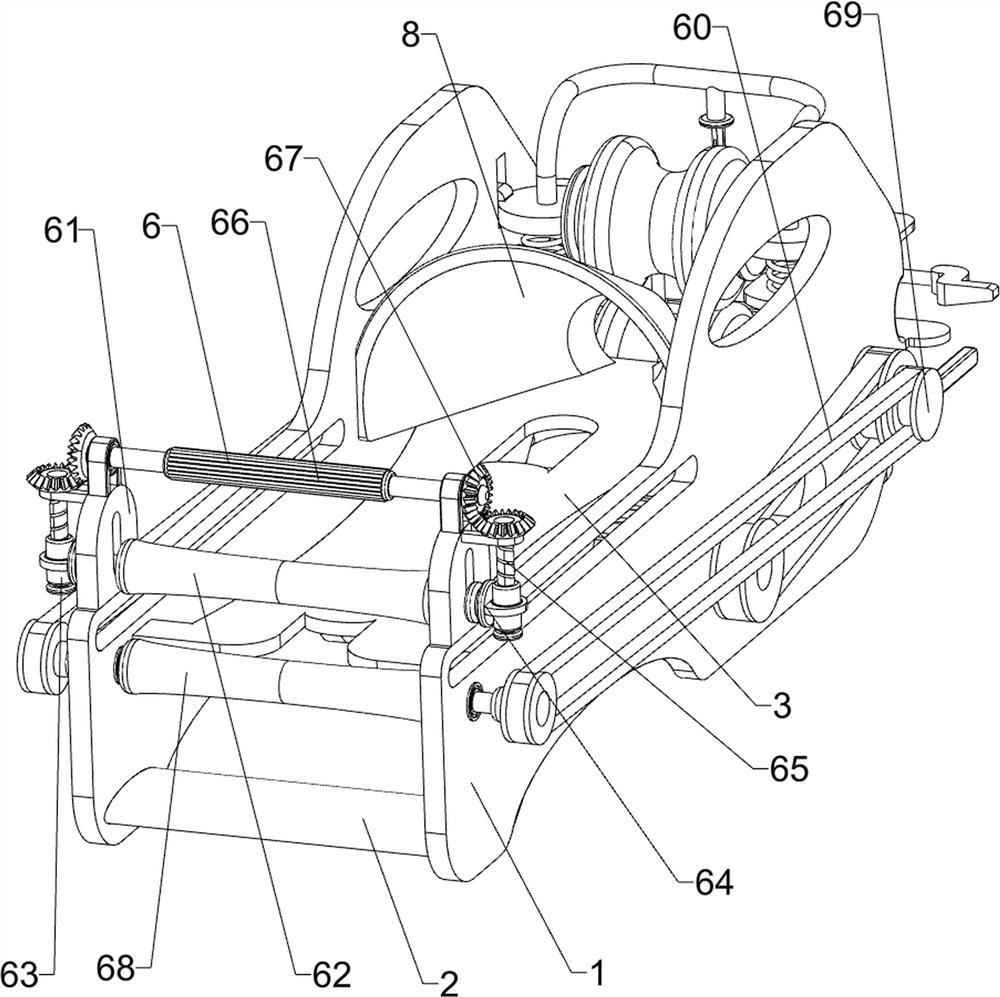

[0025] A kind of waste and old power cable sheath peeling device, such as Figure 1-2 As shown, it includes a side plate 1, a connecting plate 2 and a horizontal plate 3, a connecting plate 2 is connected between the left sides of the two side plates 1, a horizontal plate 3 is connected between the middle parts of the two side plates 1, and a cutting Component 4 and drive component 5 , the side plate 1 is provided with a cutting component 4 and a drive component 5 , and the cutting component 4 and the drive component 5 are transmission-connected.

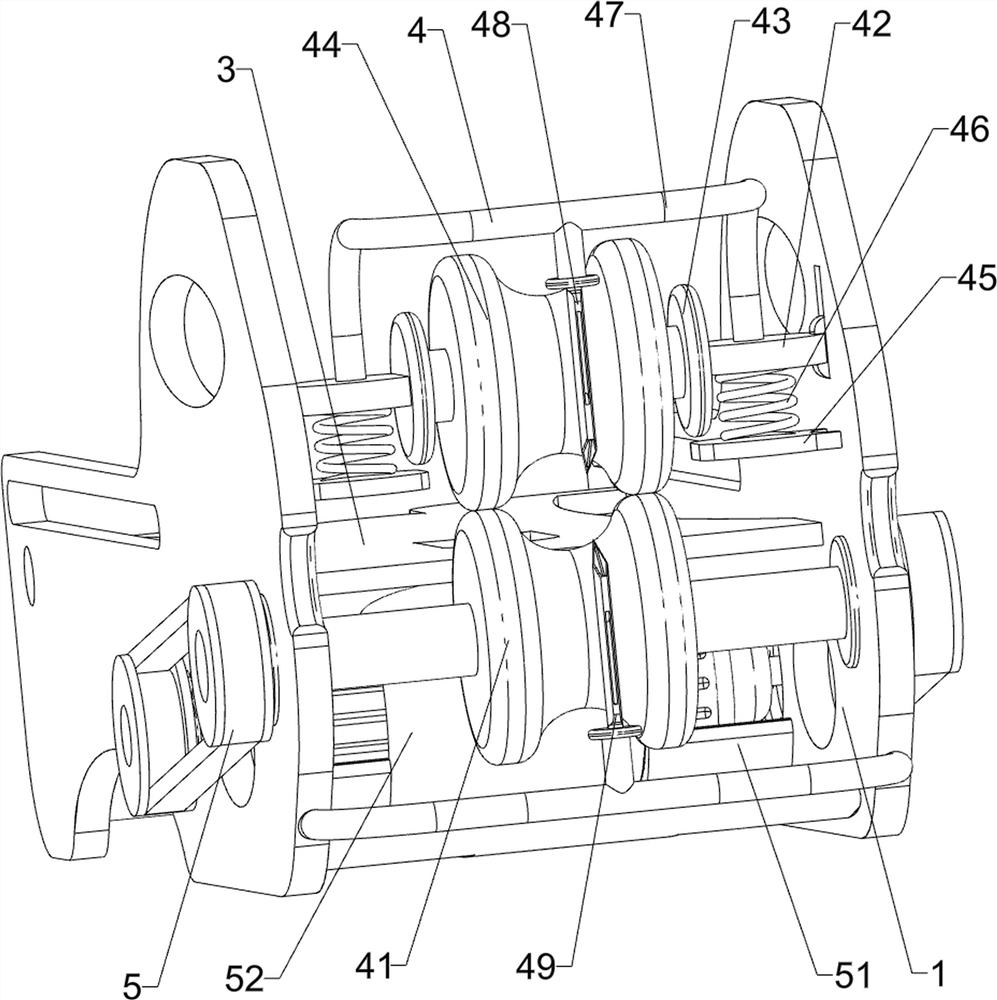

[0026] The cutting assembly 4 includes a first roller 41, a sliding plate 42, a mounting plate 43, a second roller 44, a chassis 45, a pressure spring 46, a connecting rod 47, a first cutter 48 and a second cutter 49, two pieces A first roller 41 is rotatably connected between the lower part of the right side of the side plate 1, and a sliding plate 42 is slidably connected to the upper part of the side of the side plates 1 on both ...

Embodiment 2

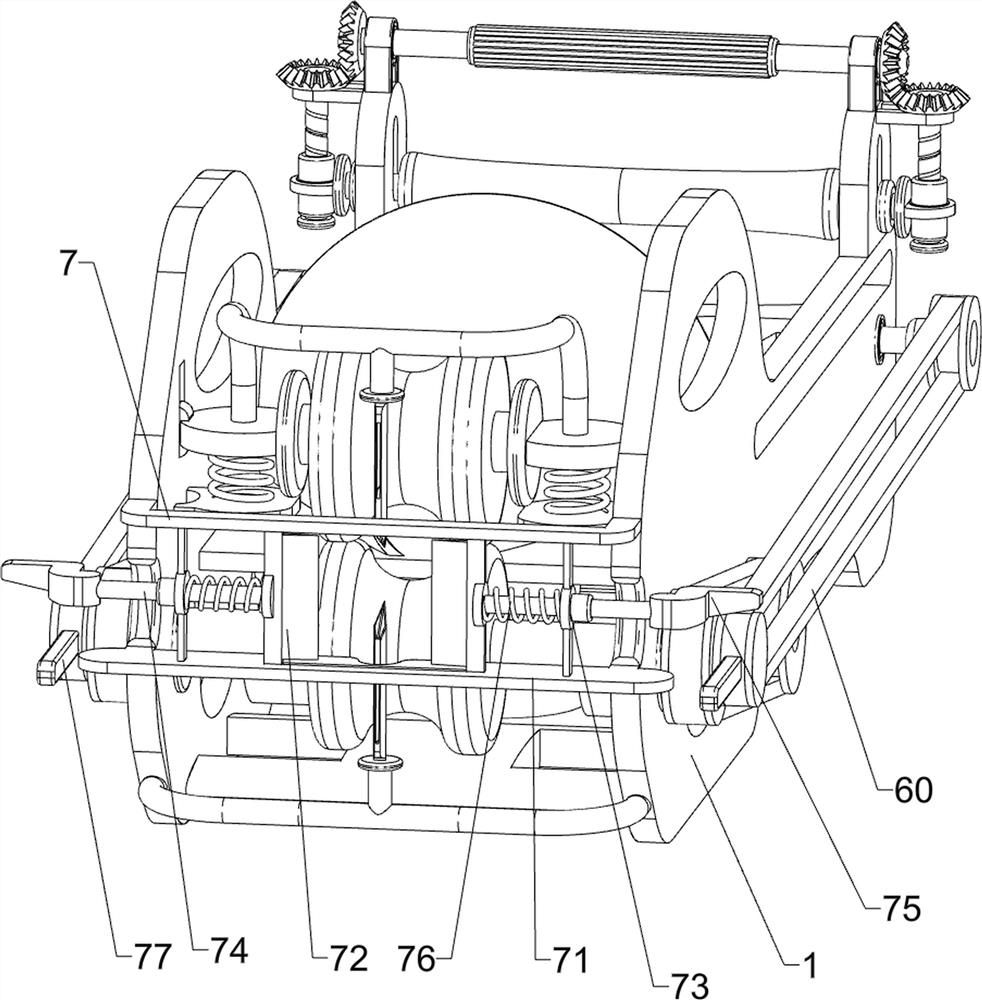

[0030] On the basis of Example 1, such as image 3 As shown, transmission assembly 6 is also included, and transmission assembly 6 includes n-shaped plate 61, upper transmission roller 62, threaded sleeve 63, T-shaped sleeve plate 64, screw rod 65, rotating shaft 66, bevel gear 67, lower transmission roller 68, Transmission wheel 69 and conveyor belt 60, n-shaped plate 61 is connected to the left side of the top of both side plates 1, and an upper conveying roller 62 is slidably connected between the two n-shaped plates 61, and the upper conveying roller 62 and n-shaped plate 61 Rotate fit, the front and rear sides of the upper loser 62 are rotatably connected with a T-shaped sleeve plate 64, the T-shaped sleeve plate 64 is connected with a threaded sleeve 63, and the threaded sleeve 63 is threadedly connected with a screw rod 65, and the screw rod 65 and the n-shaped plate 61 rotating fit, rotating shaft 66 is connected between the n-shaped plates 61 tops on both sides, the t...

Embodiment 3

[0033] On the basis of Example 2, such as Figure 4 As shown, a cut-off assembly 7 is also included, and the cut-off assembly 7 includes a chute plate 71, a cutting piece 72, a sliding sleeve 73, a guide rod 74, an L-shaped wedge 75, a return spring 76 and a swing rod 77, and two side plates 1. A chute plate 71 is connected between the upper and lower sides on the right side, and a cutting piece 72 is slidably connected between the front and rear sides of the chute plate 71 on both sides, and the front and rear sides of the chute plate 71 on both sides are connected Sliding sleeve 73 is arranged, and cutting piece 72 is connected with guide rod 74, and guide rod 74 is slidably matched with sliding sleeve 73, is connected with back-moving spring 76 between cutting piece 72 and sliding sleeve 73, and one end of both side guide rods 74 is far away from each other. An L-shaped wedge 75 is connected, and a swing rod 77 is connected to the two conveyor belts 60, and the swing rod 77...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com