Radiation curable compositions for additive fabrication

A technology for additive manufacturing and composition, applied in the field of thermosetting compositions, which can solve problems such as poor curing speed and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

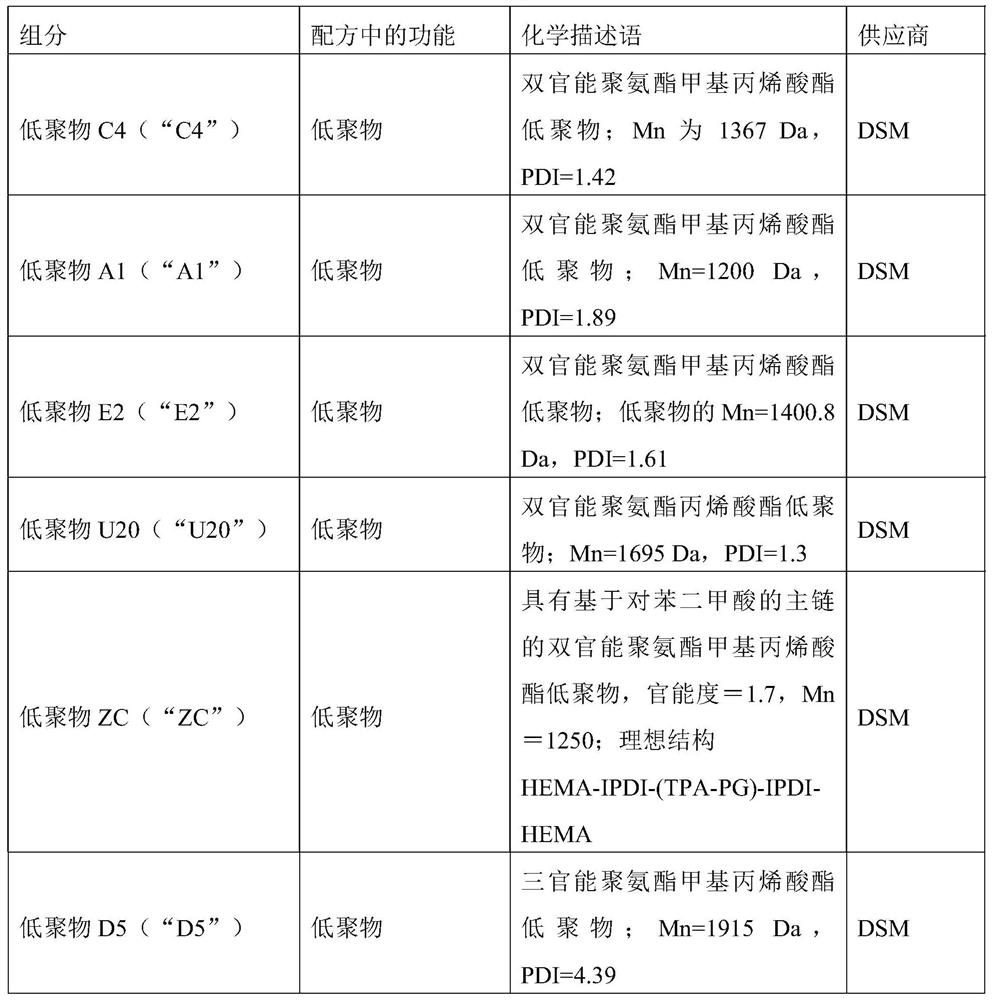

[0155] These examples illustrate embodiments of additively manufactured radiation curable compositions useful in the present invention. Table 1 describes the various components of the radiation curable composition for additive manufacturing used in this example. Meanwhile, Table 2A and Table 2B describe the various subcomponents used to synthesize the oligomers mentioned in Table 1 and used in the examples of the present invention. Table 3 lists the compositional composition of each of the formulations evaluated here. Finally, Table 4A, Table 4B, and Table 4C describe various performance characteristics of one or more of the formulations used herein.

[0156] Table 1

[0157]

[0158]

[0159] Table 2A - Oligomer Reactants

[0160]

[0161]

[0162] Table 2B - Oligomer Reactants

[0163] Amounts are listed in equivalents unless otherwise noted

[0164]

[0165] Synthesis of oligomers

[0166] The oligomers used in the following examples were synthesized acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap