Continuous leather spraying device for luggage processing

A technology of spraying device and leather, applied in the directions of spraying device, liquid spraying device, device for coating liquid on the surface, etc., can solve the problems of increasing the energy consumption and cost of leather production, affecting the quality of leather and luggage products, and a large amount of waste water, etc. Achieve the effect of improving the reuse rate, preventing uneven spray coating, and cleaning thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

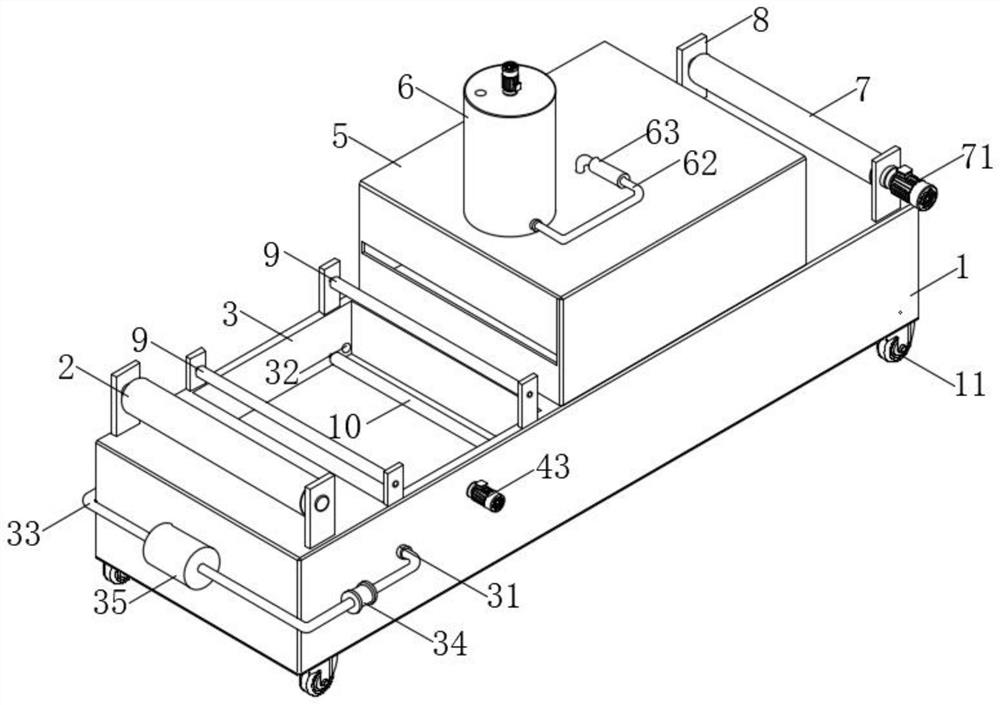

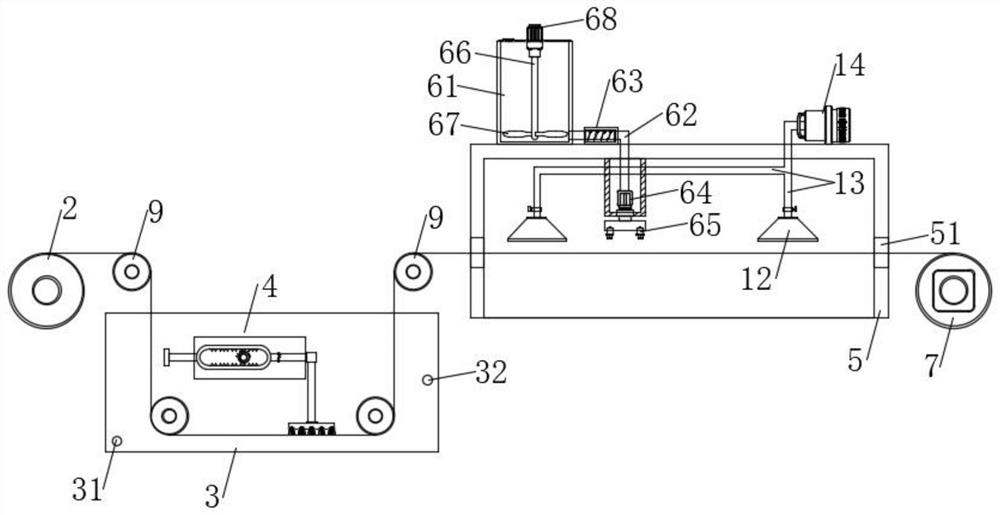

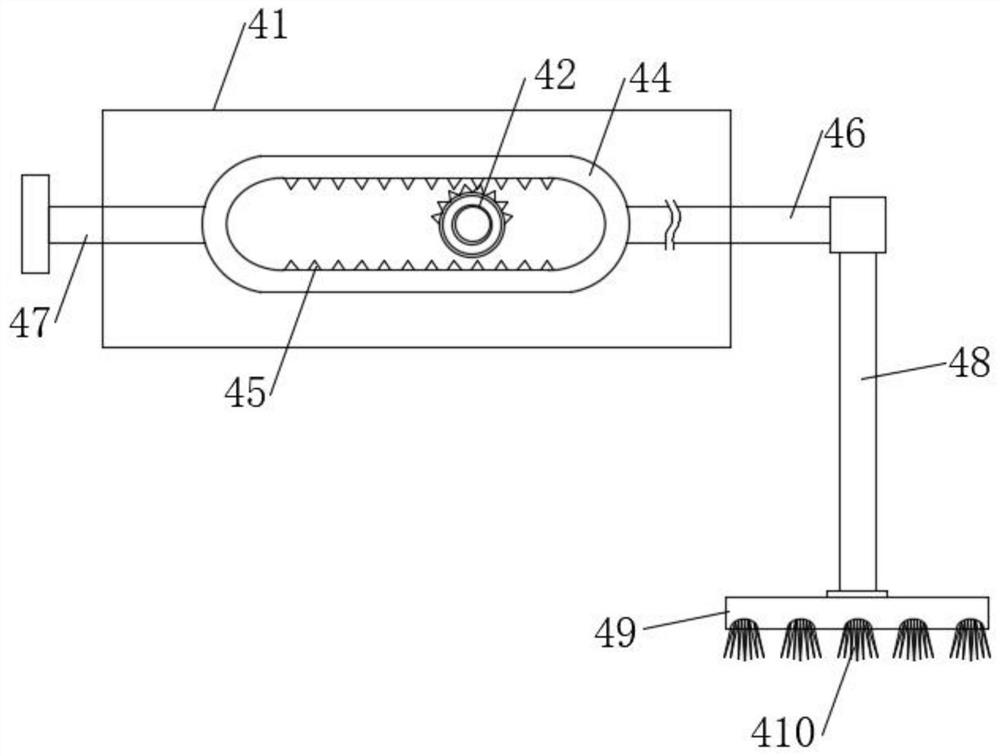

[0025] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a leather continuous spraying device for luggage processing, including a processing table 1 and a discharge roller 2, and one side of the top of the processing table 1 is rotated by a support plate 8. A discharge roller 2, leather is wound on the discharge roller 2, a cleaning water tank 3 is fixedly embedded in the upper end of the processing table 1 on one side of the discharge roller 2, and a water circulation mechanism is provided on the cleaning water tank 3, The inside of the cleaning water tank 3 is fixedly equipped with a reciprocating cleaning mechanism 4, and the processing table 1 on the side of the cleaning water tank 3 away from the discharge roller 2 is fixedly installed with a protective partition 5, and the opposite sides of the protective partition 5 are There are communication ports 51 on each of them, and the protective partition 5 is equipped with a spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com