A spraying method for small parts

A technology of small parts and parts, applied in the field of spraying processing technology, can solve the problems of difficulty in meeting the production needs and delivery of large-scale parts, affecting the assembly and use performance of parts, uneven color and film thickness, and improving the quality of spraying products. The effect of convenient operation, improved utilization rate and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

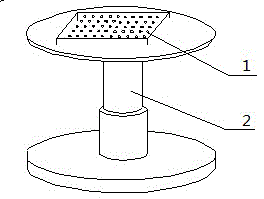

[0019] see figure 1 , a spraying method for small parts, comprising the steps of:

[0020] a. Clamping of parts: fix the parts on the matching socket fixture 1, and then place them on the tooling 2 of the round table top that can rotate freely;

[0021] b. One-time spraying: Spray one side of the part, the tooling rotates slowly at a speed of 2 revolutions per minute, and a small spray gun with a caliber of 0.3mm is used to spray at 15 00 In the direction of the included angle, the straight line distance is 10mm, and the compressed air pressure is 0.35Mpa for spraying. The spraying of parts is carried out by four times of diagonal spraying and one plane spraying;

[0022] c. Low-temperature baking: After spraying, move the jig together with the parts in parallel to a hot air device with low-temperature baking at a temperature of 20°C, pre-baking it for 25 minutes, and wait for the sprayed surface to dry;

[0023] d. Secondary spraying: After low-temperature baking, turn the ...

Embodiment 2

[0026] see figure 1 , a spraying method for small parts, comprising the steps of:

[0027] a. Clamping of parts: fix the parts on the matching socket fixture 1, and then place them on the tooling 2 of the round table top that can rotate freely;

[0028] b. One-time spraying: Spray one side of the part, the tooling rotates slowly at a speed of 23 rpm, and a small spray gun is used to spray at 30 0 In the direction of the included angle, the straight line distance is 20mm, and the compressed air pressure is 0.4Mpa for spraying. The spraying of parts is carried out by four times of diagonal spraying and one plane spraying;

[0029] c. Low-temperature baking: After spraying, move the jig together with the parts in parallel to a hot air device with low-temperature baking at a temperature of 25°C, pre-baking it for 30 minutes, and wait for the sprayed surface to dry;

[0030] d. Secondary spraying: After low-temperature baking, turn the part over and spray it on the other unpainte...

Embodiment 3

[0033] see figure 1 , a spraying method for small parts, comprising the steps of:

[0034] a. Parts clamping: fix the parts on the matching parallel fixture, and then place them on the tooling 2 of the round table top that can rotate freely;

[0035] b. One-time spraying: Spray one side of the part, the tooling rotates slowly at a speed of 3 revolutions per minute, and a small spray gun is used to spray at 45 0 In the direction of the included angle, the straight line distance is 30mm, and the compressed air pressure is 0.5Mpa for spraying. The spraying of parts is carried out by four times of diagonal spraying and one plane spraying;

[0036] c. Low-temperature baking: After spraying, move the fixture together with the parts in parallel to a hot air device with low-temperature baking at a temperature of 30°C, pre-baking it for 35 minutes, and wait for the sprayed surface to dry;

[0037] d. Secondary spraying: After low-temperature baking, turn the part over and spray it on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com