Patents

Literature

30results about How to "Flexible seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

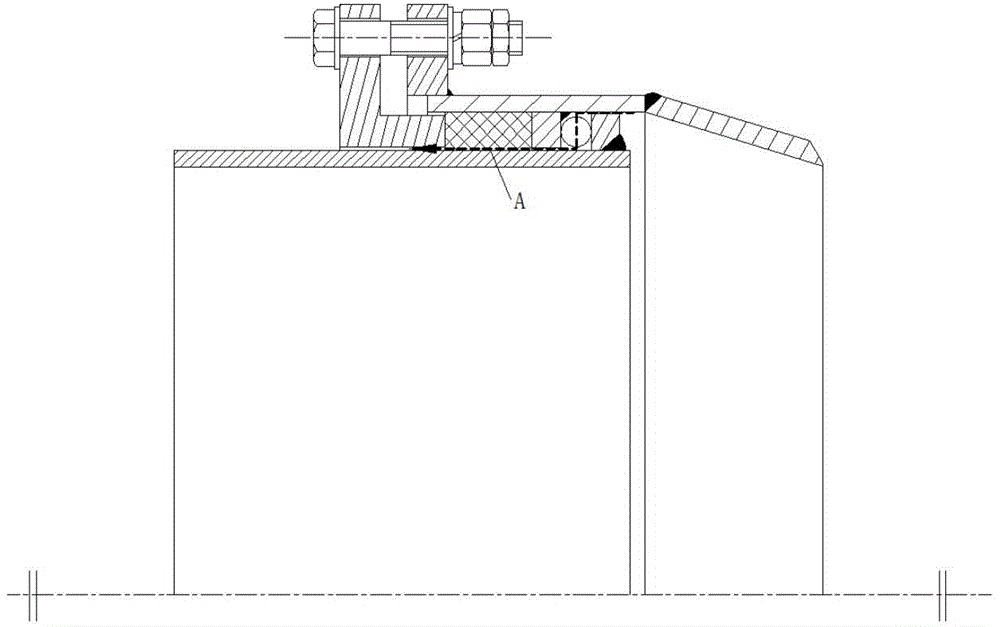

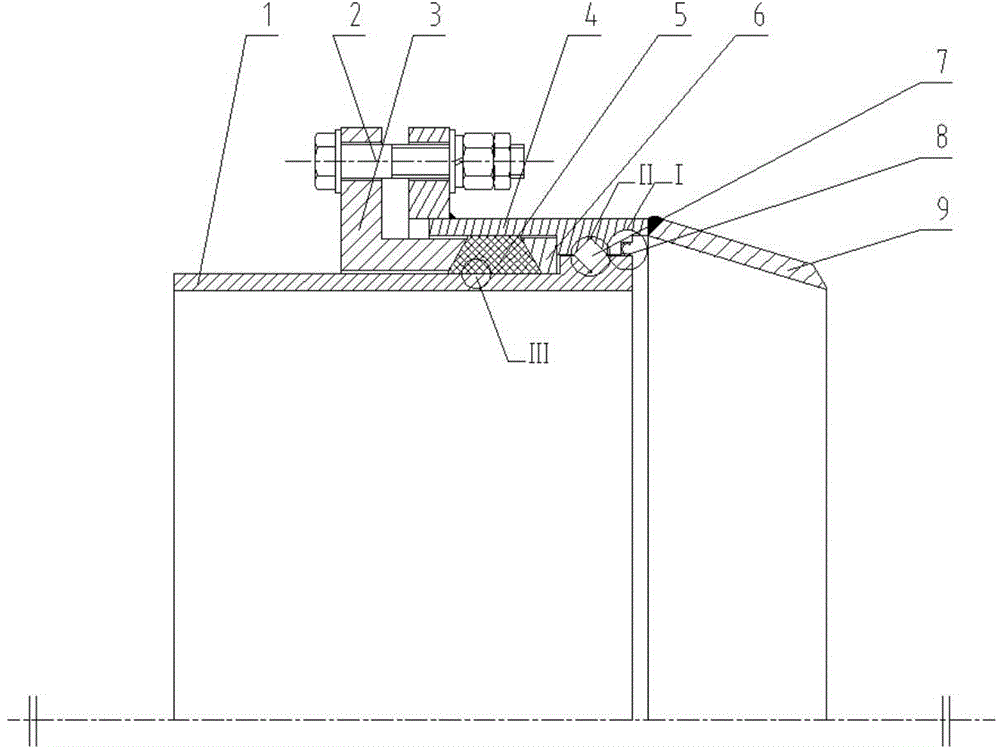

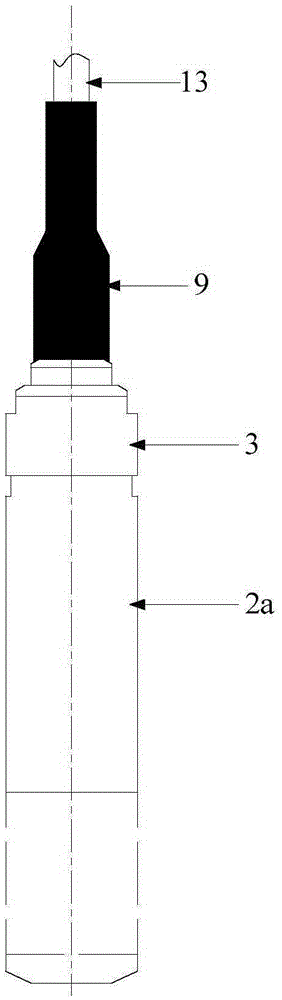

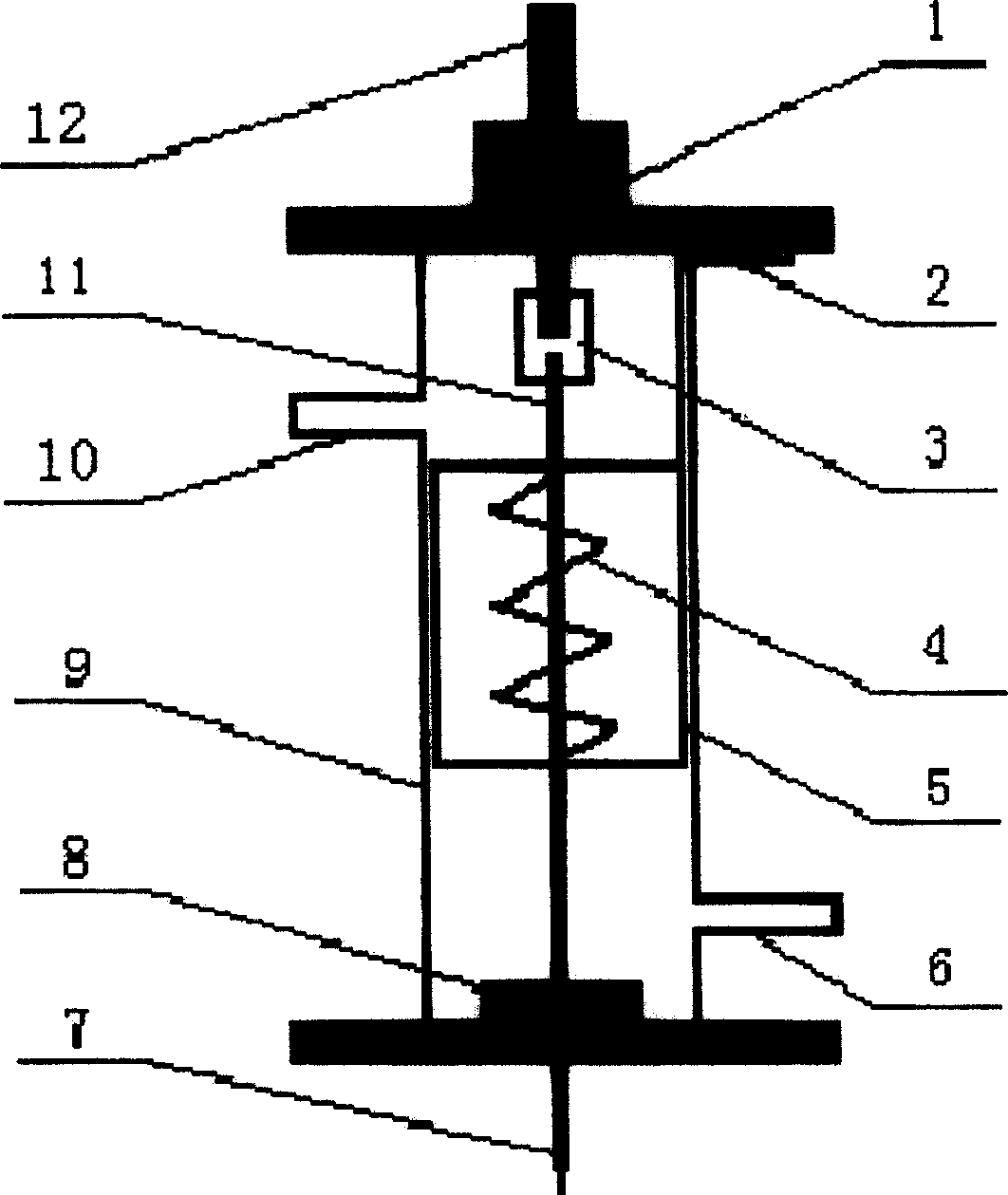

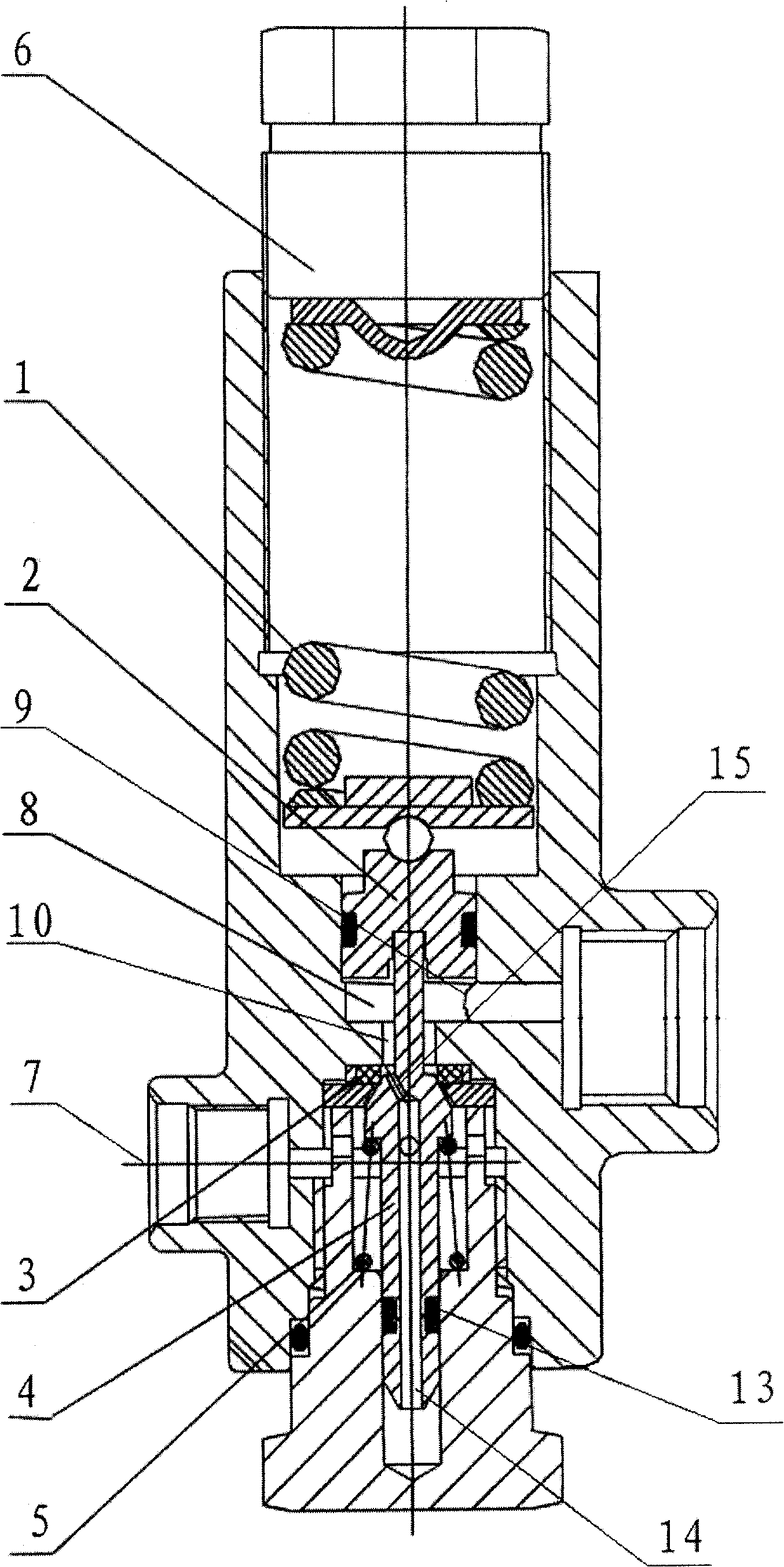

Sealing mechanism preventing gas exchange

ActiveCN104728448AAvoid swappingAvoid enteringEngine sealsSludge treatment by pyrolysisGas exchangeMechanical engineering

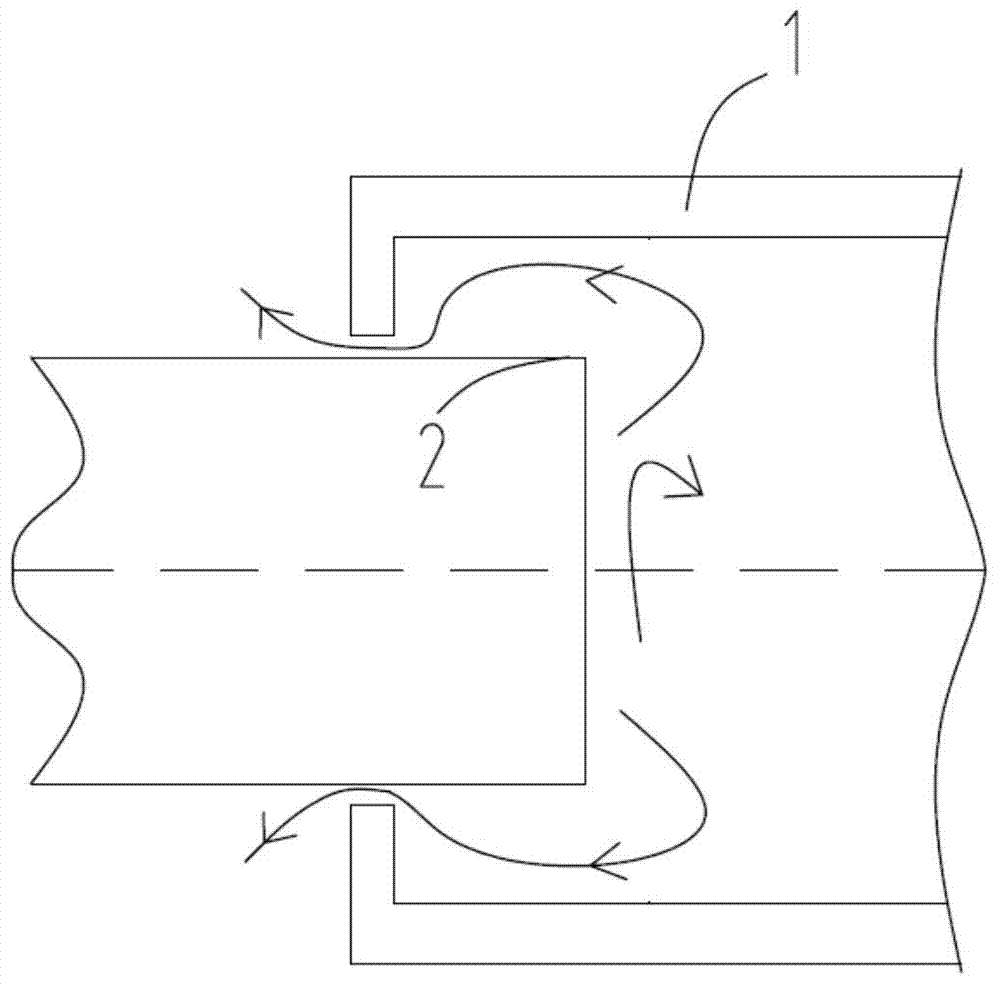

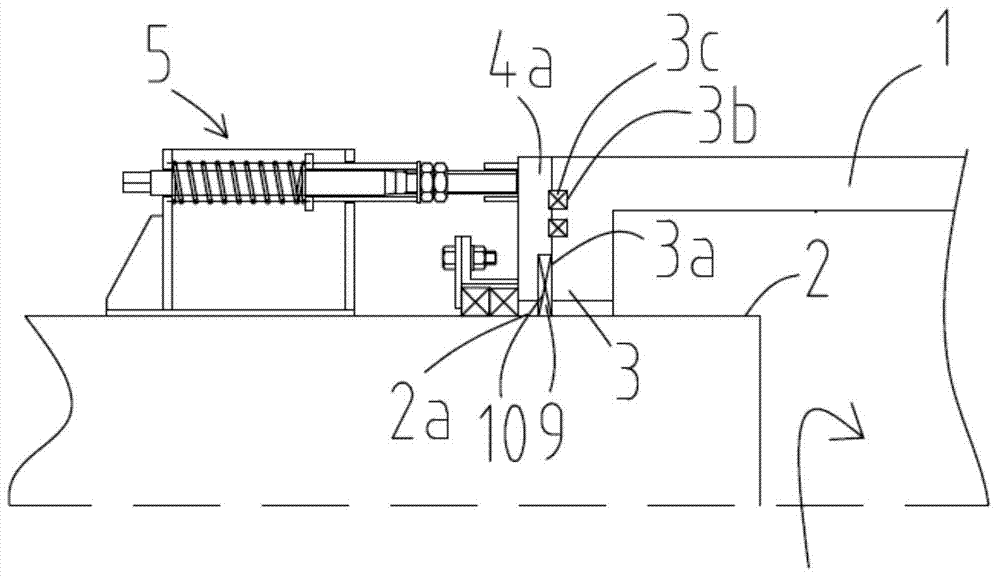

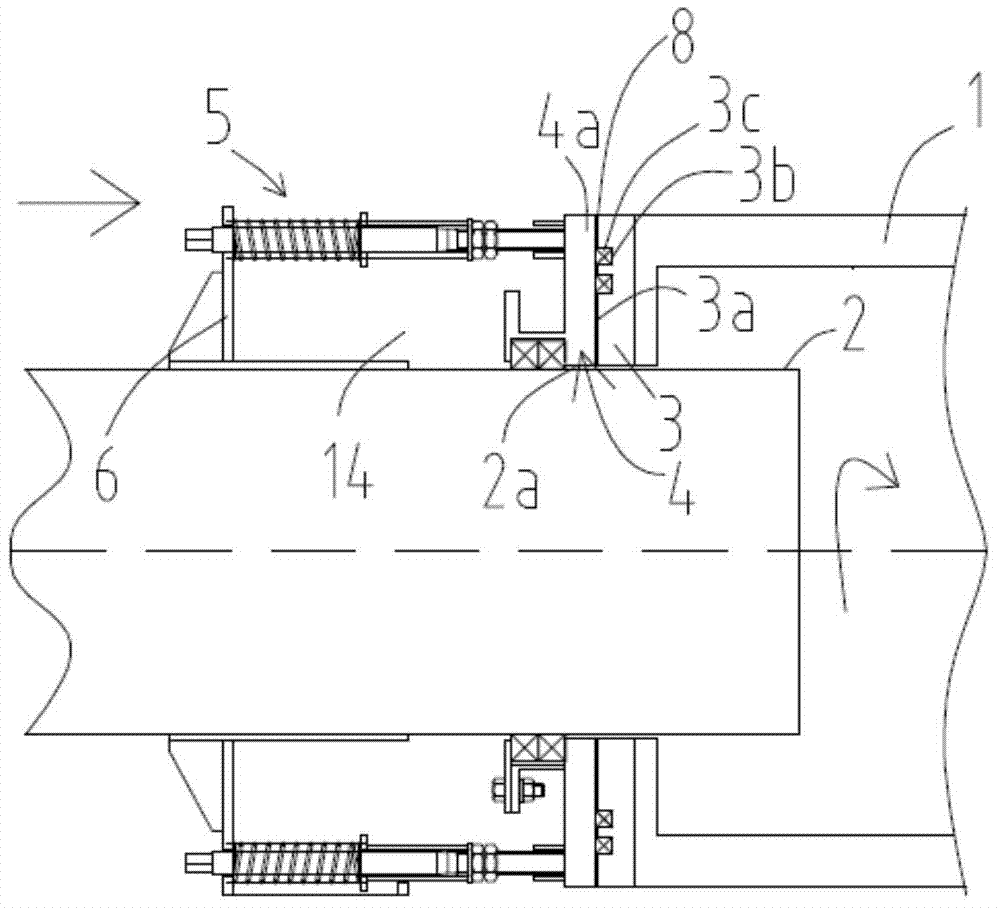

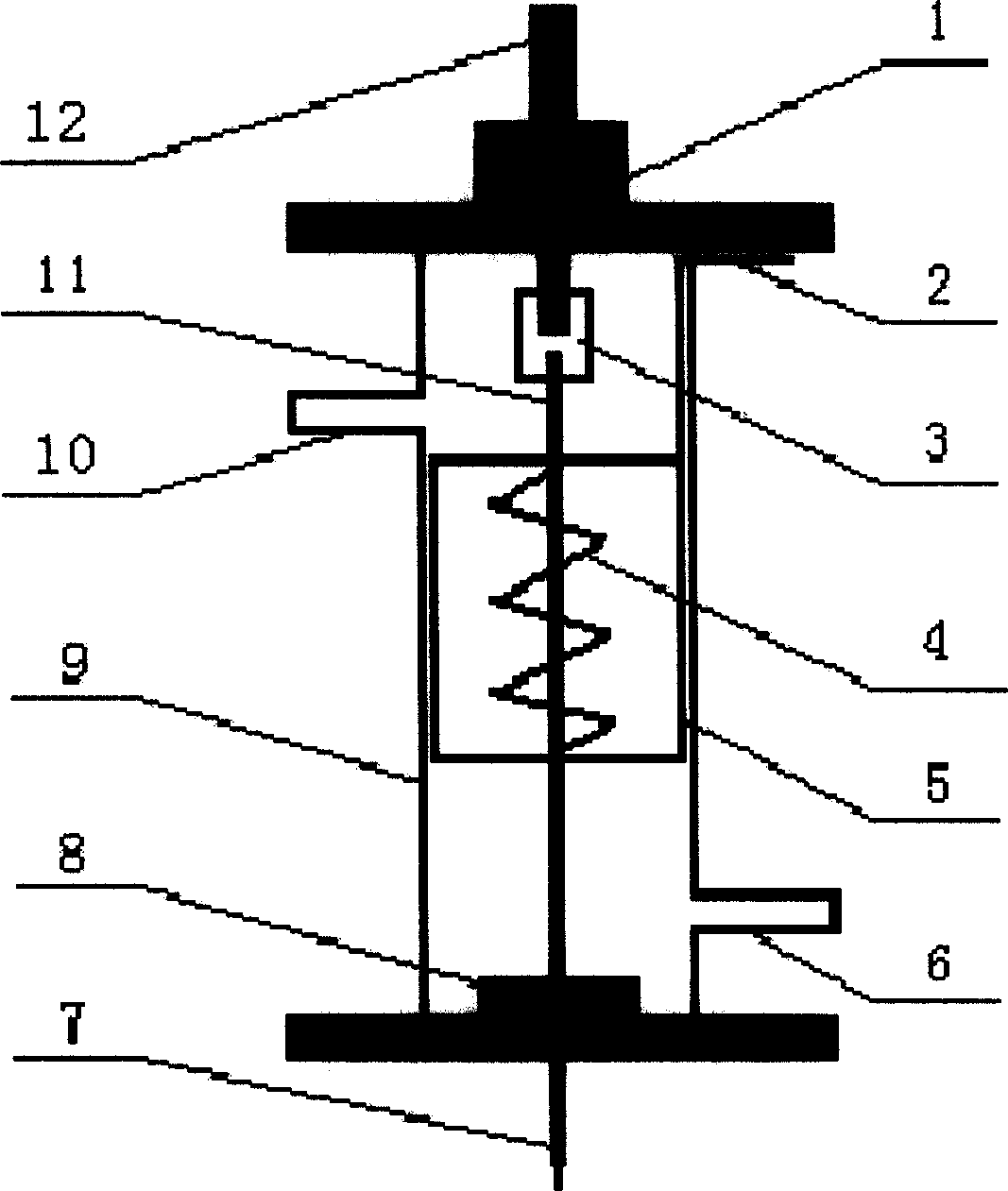

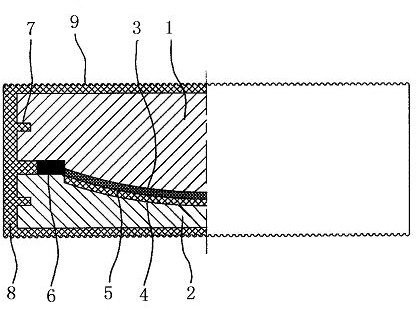

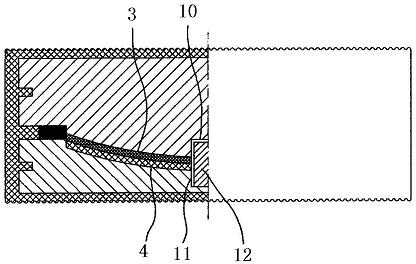

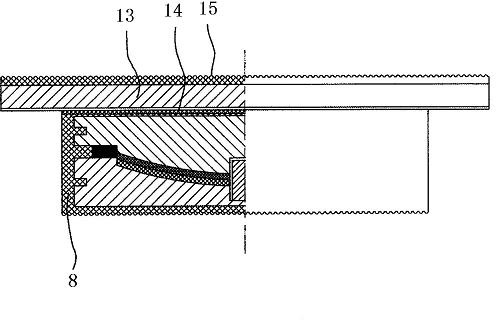

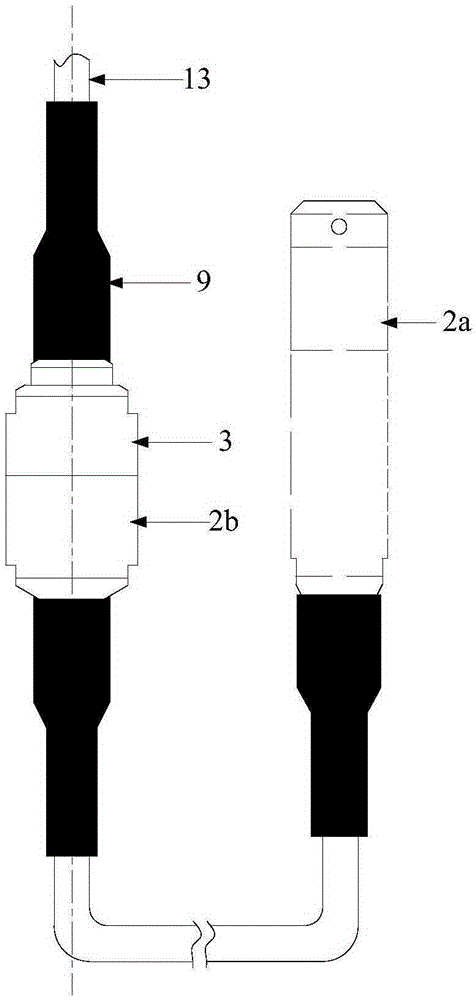

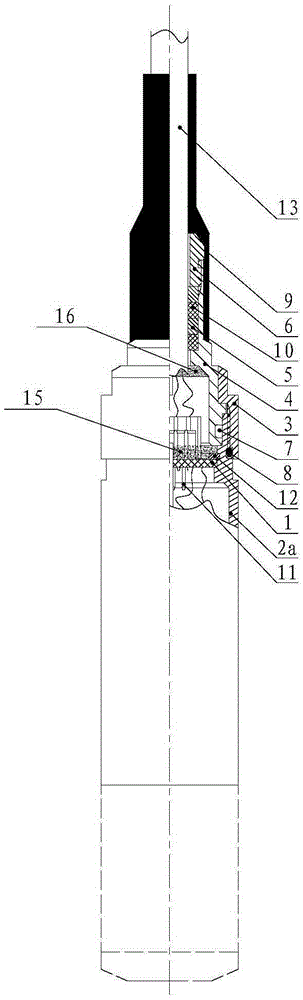

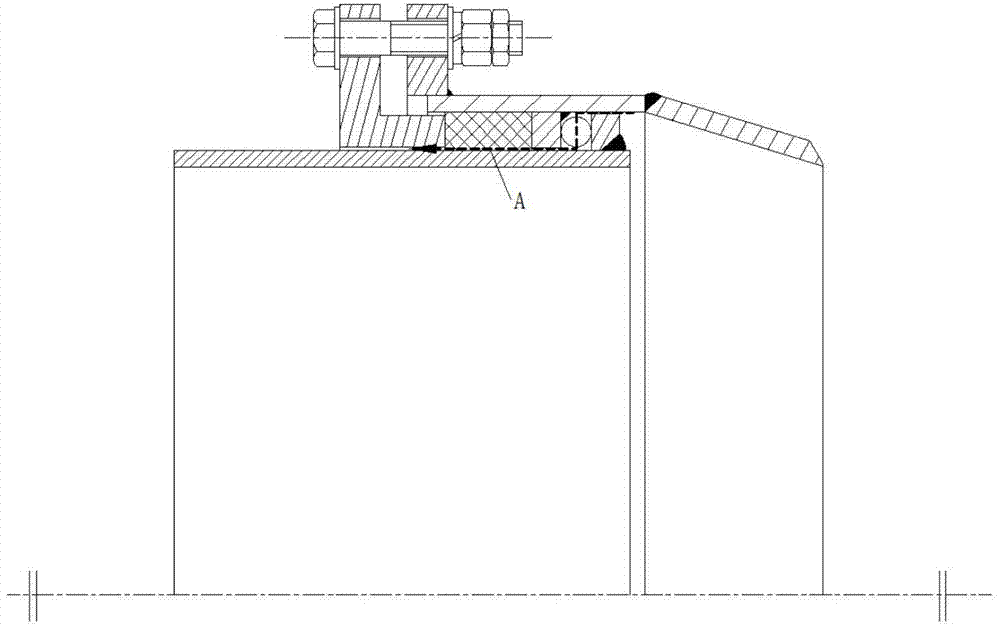

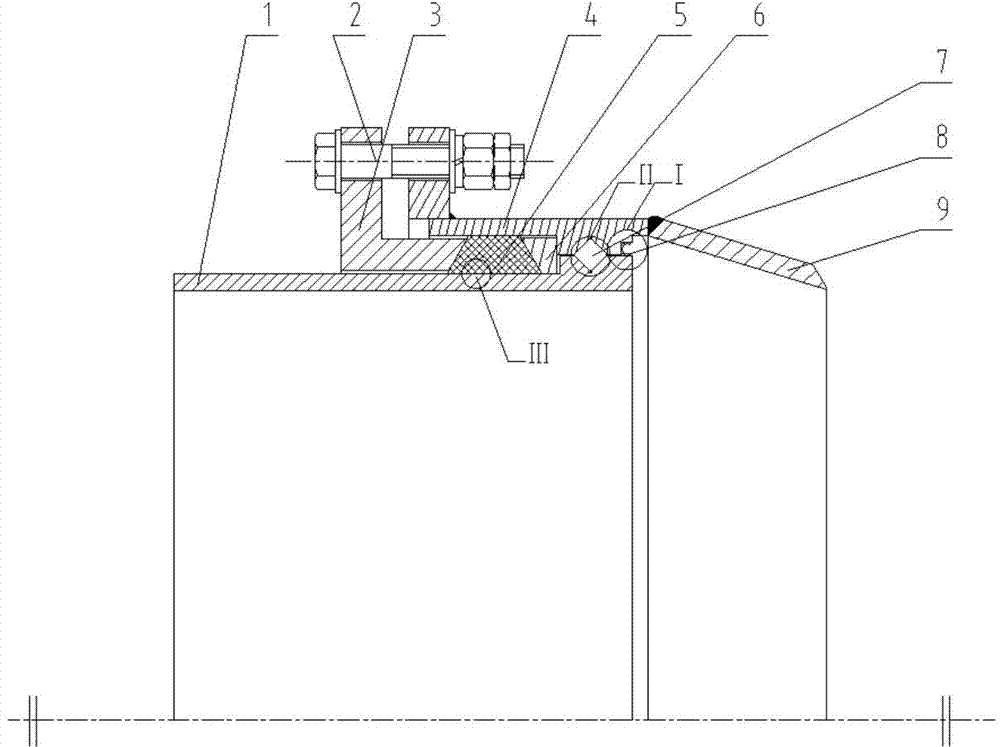

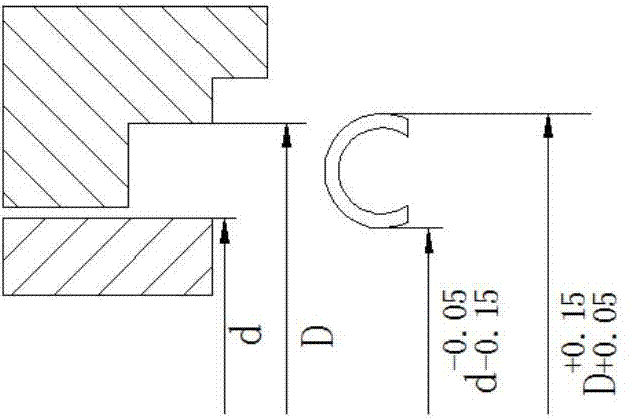

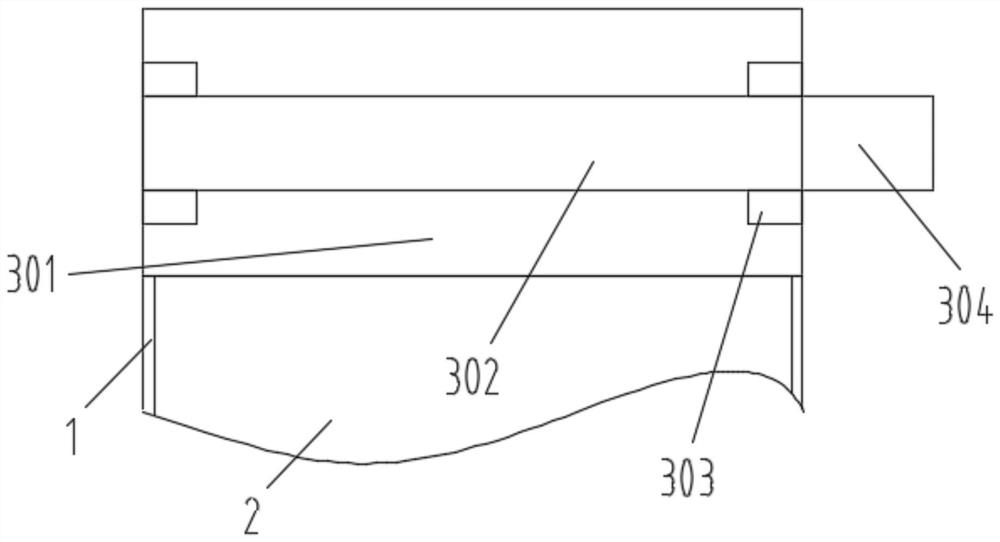

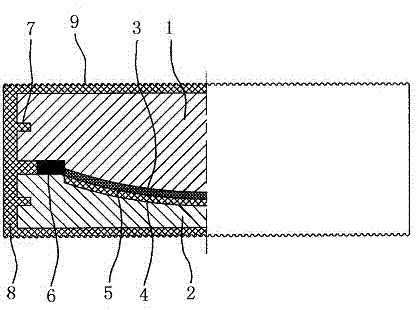

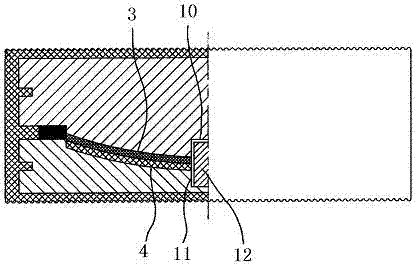

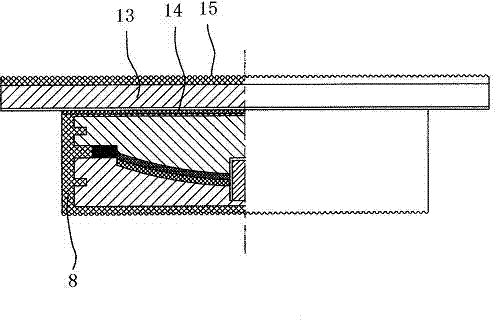

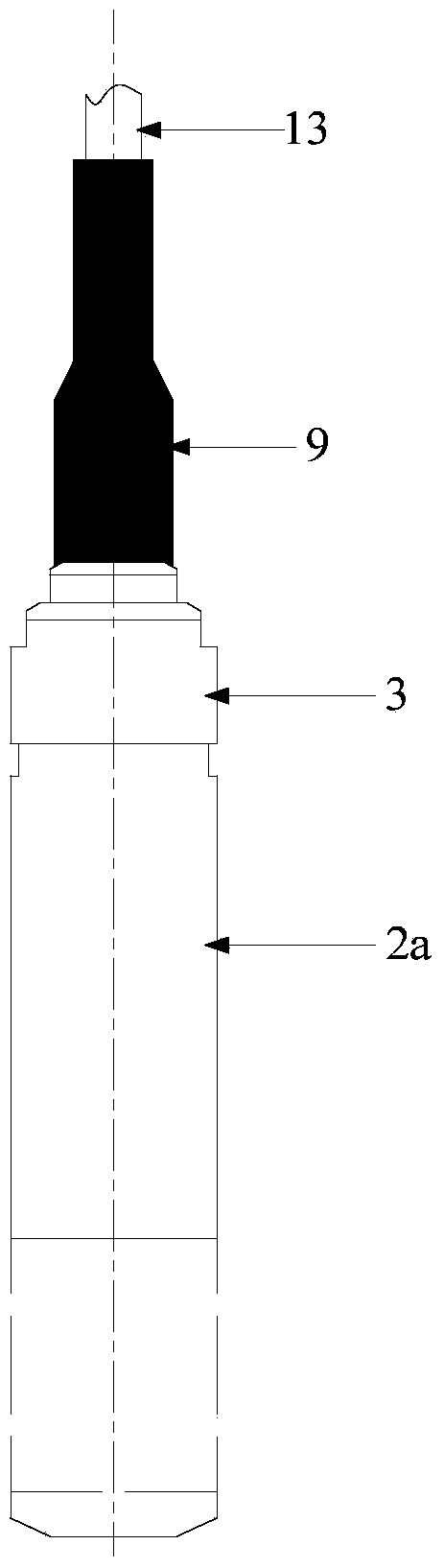

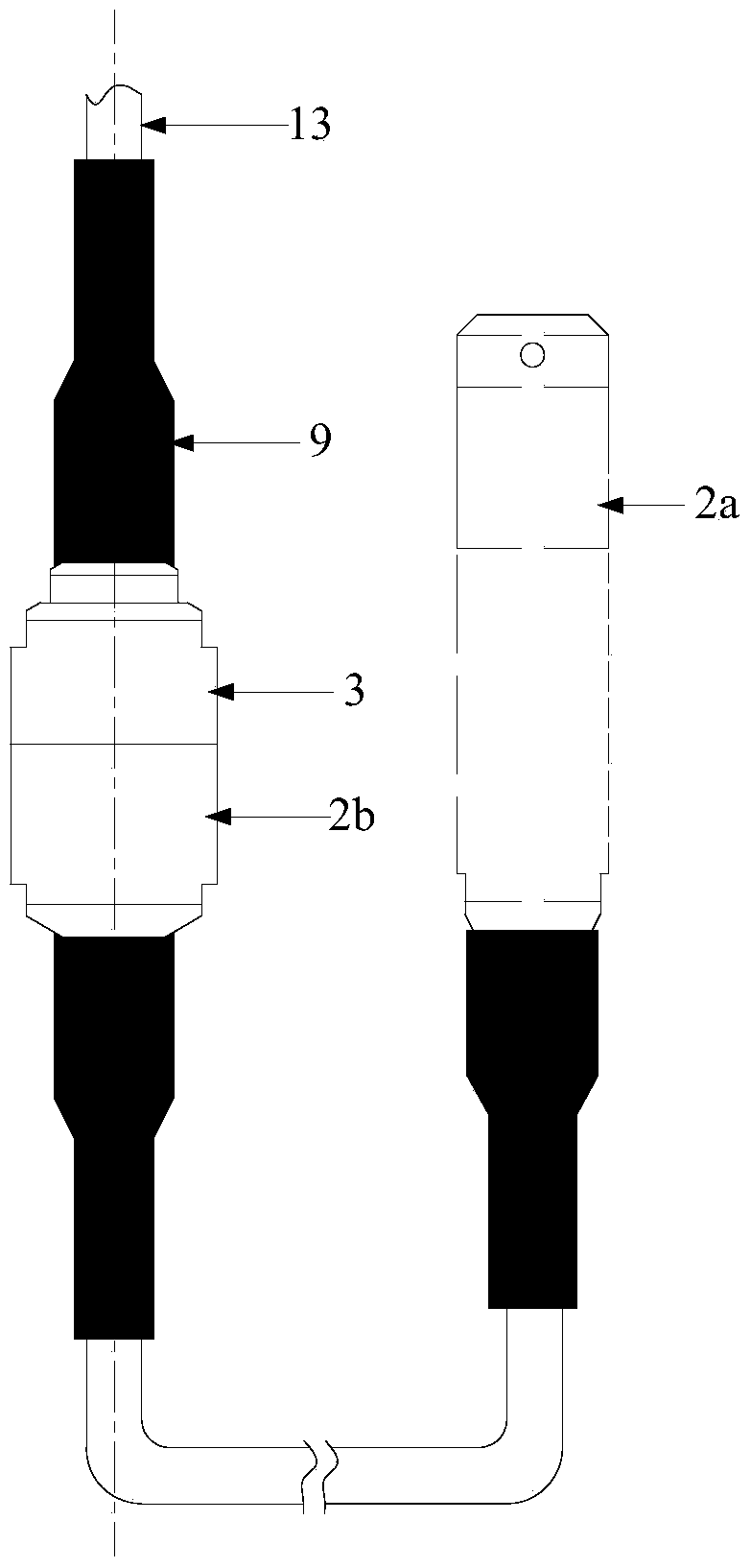

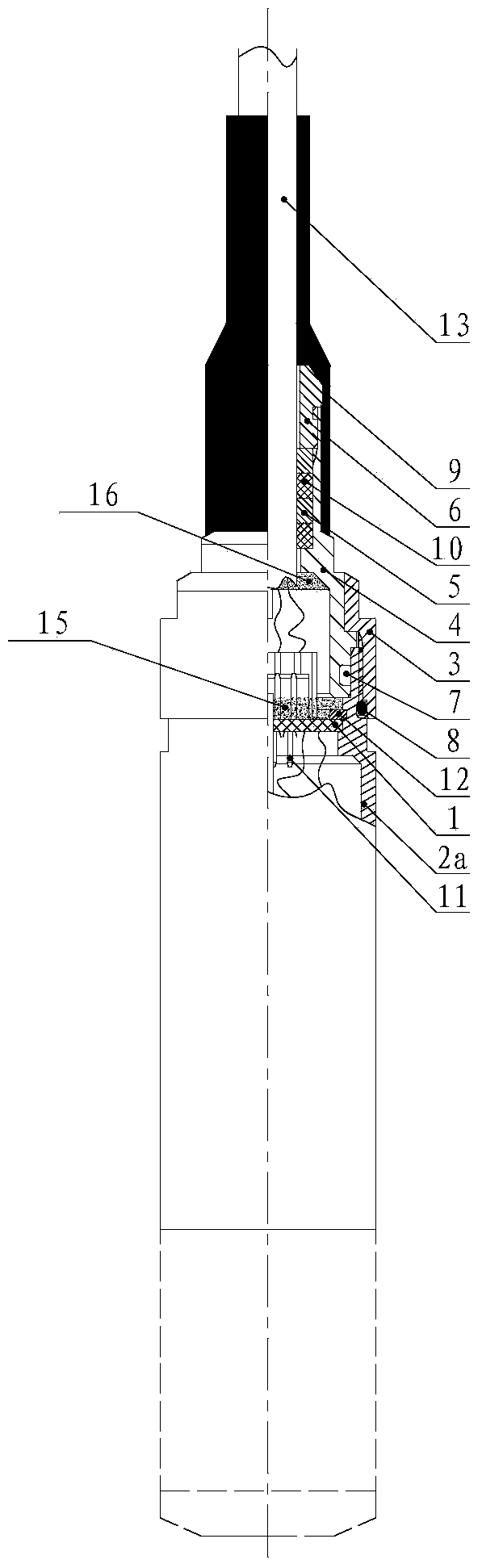

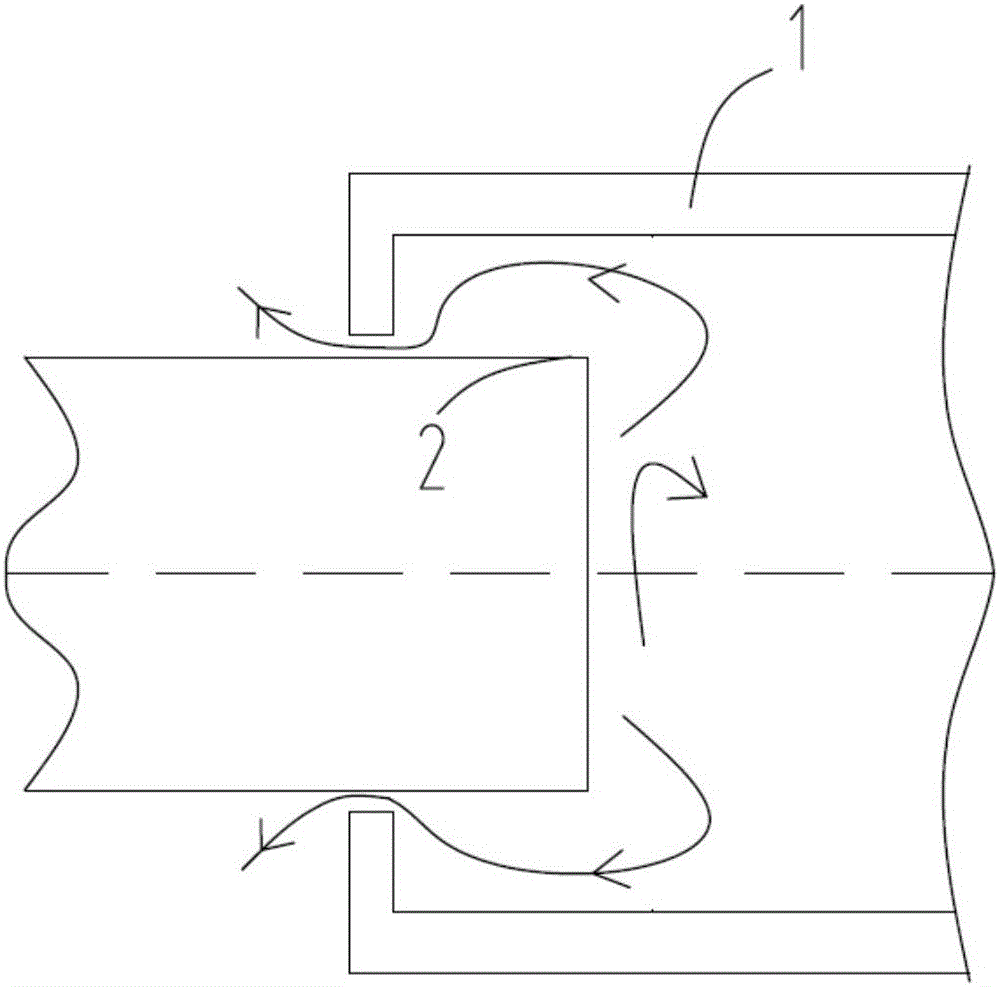

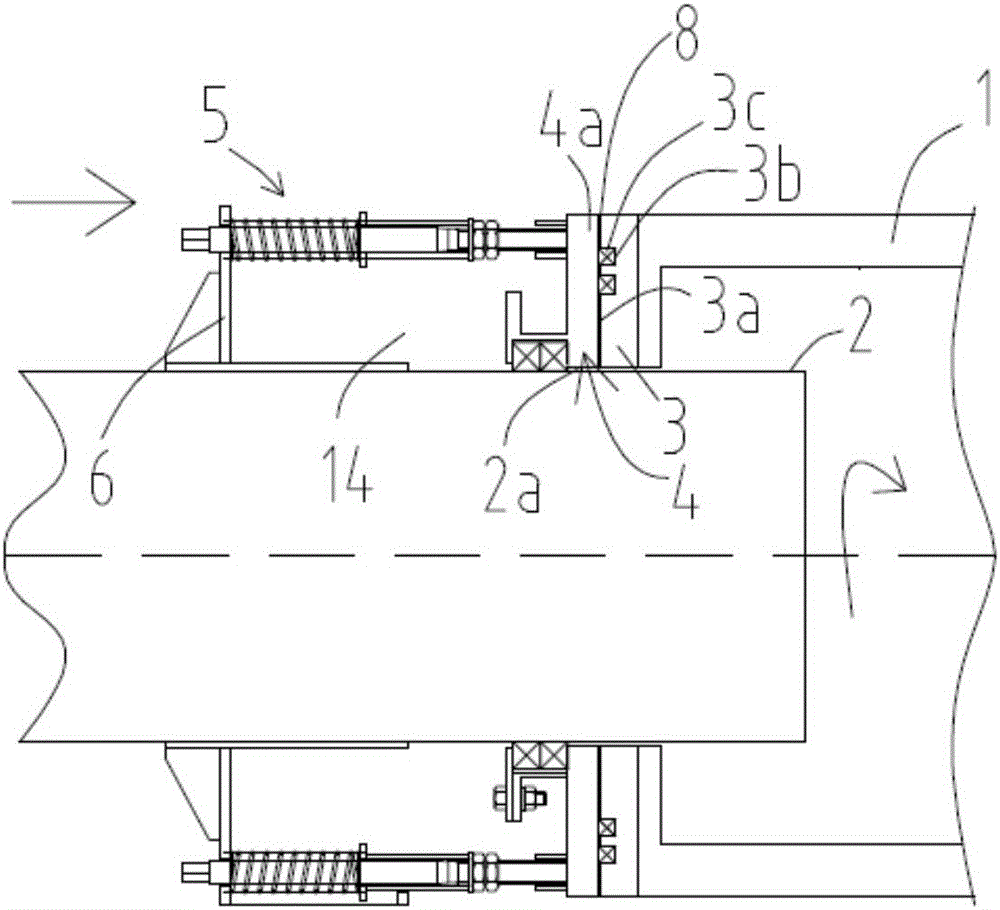

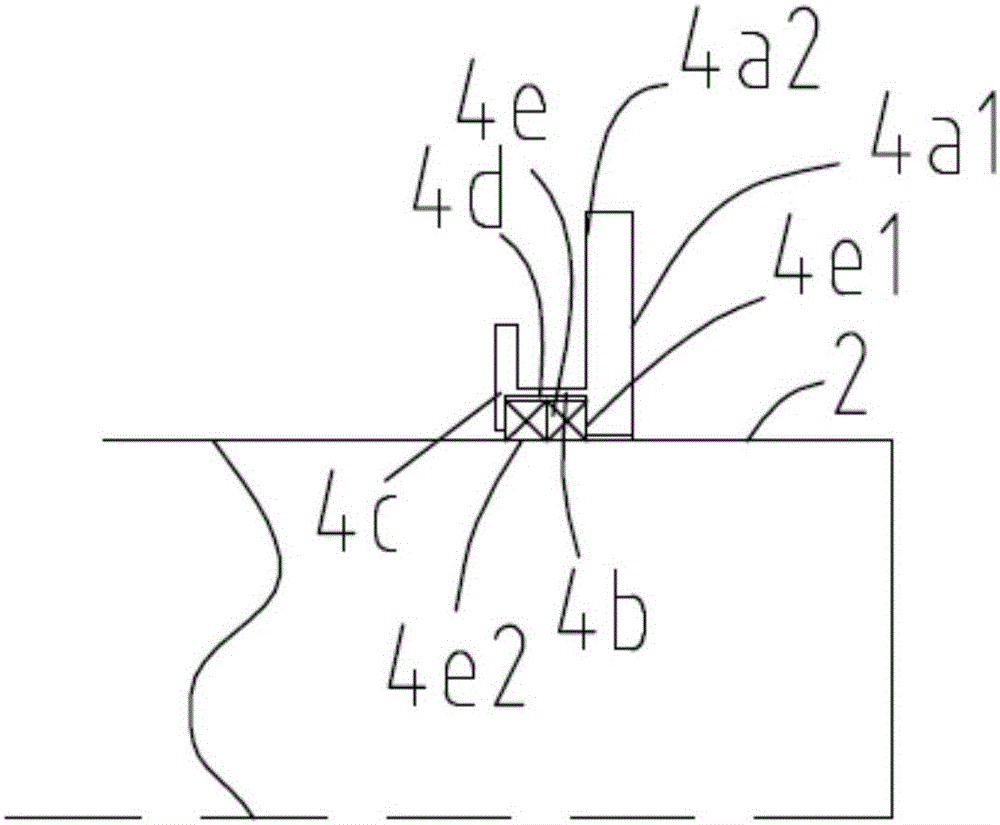

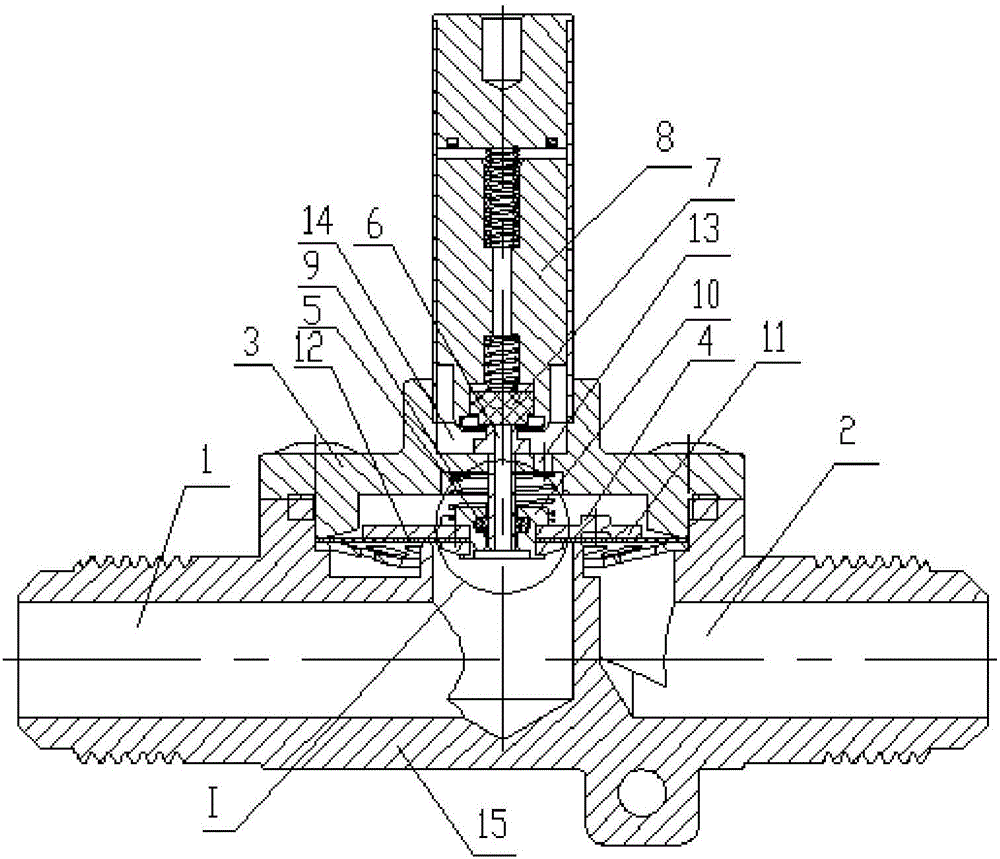

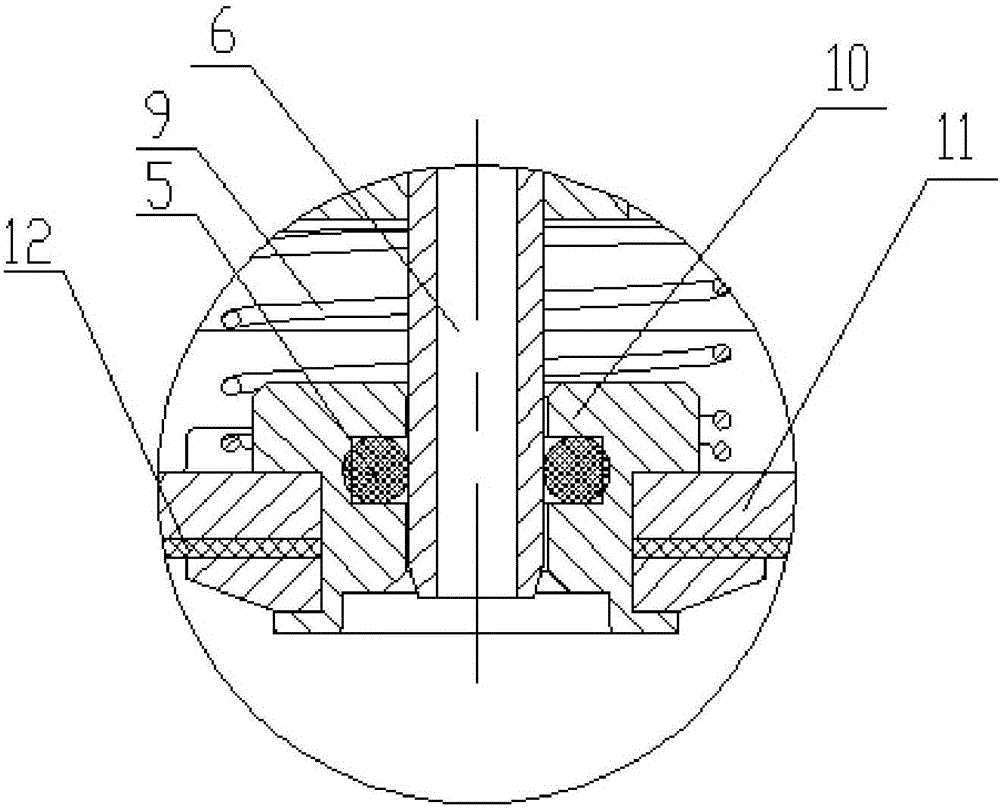

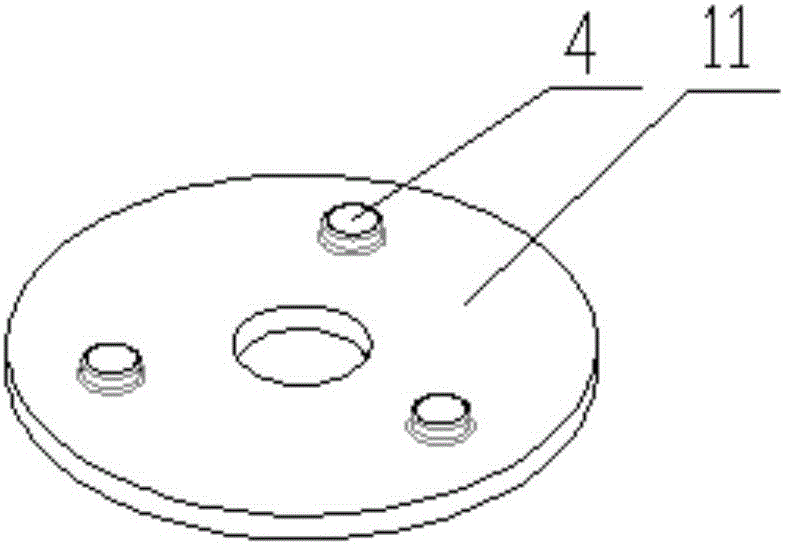

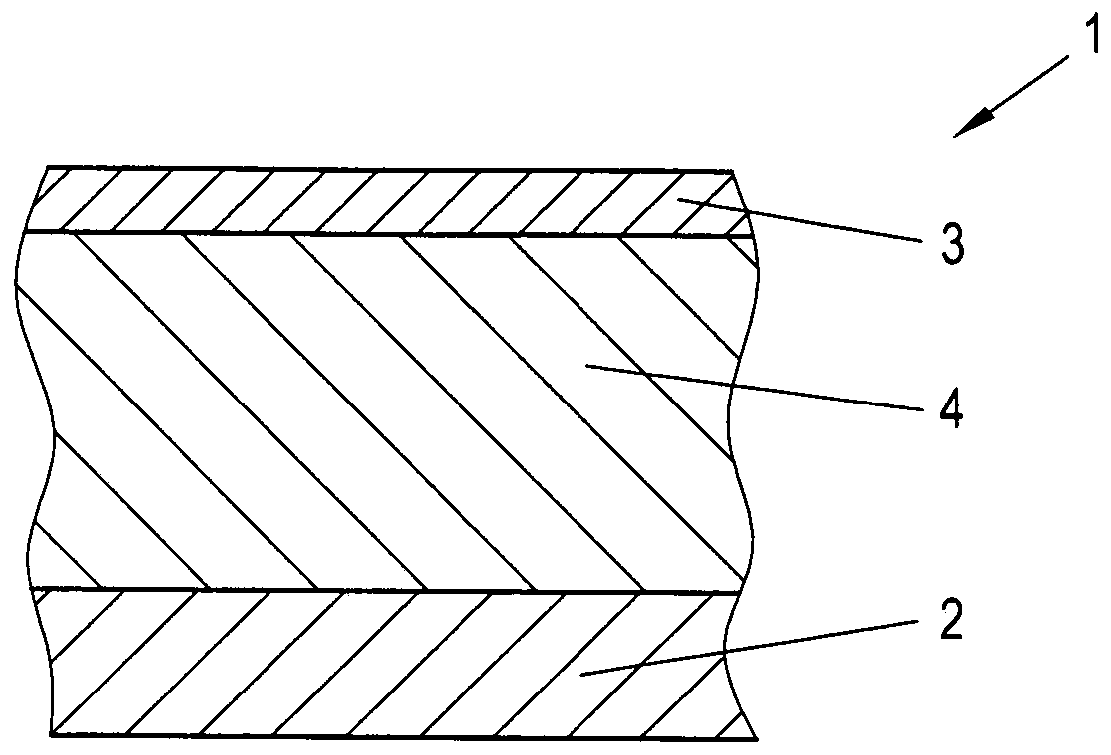

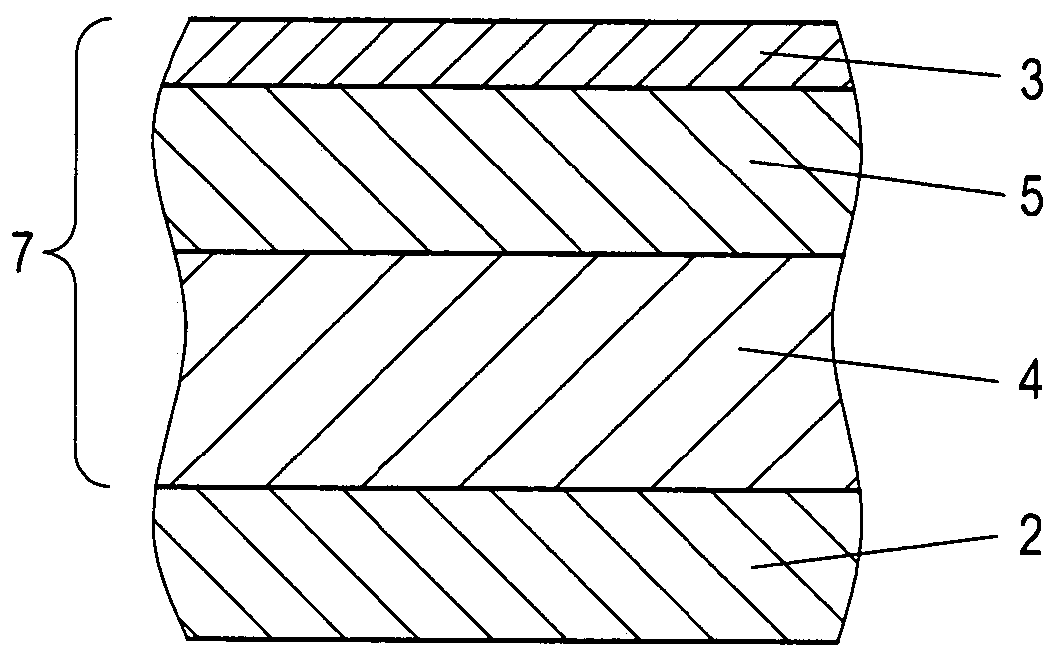

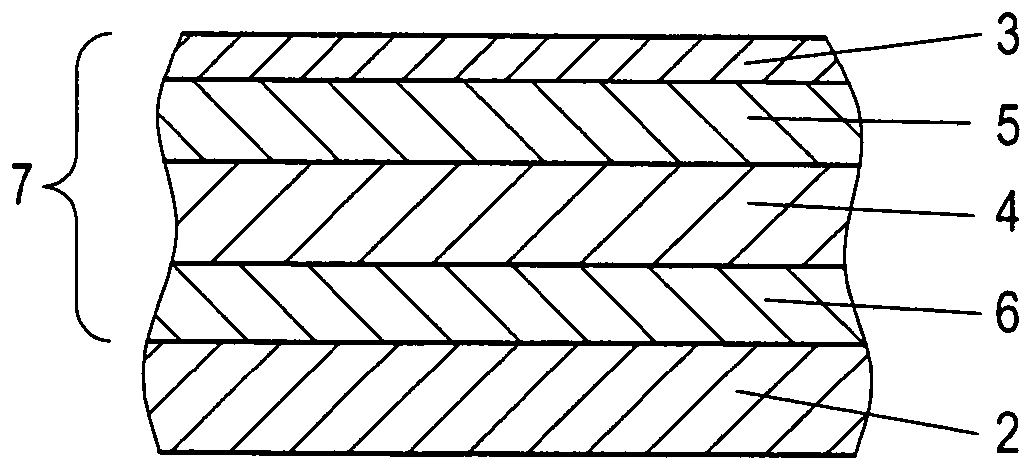

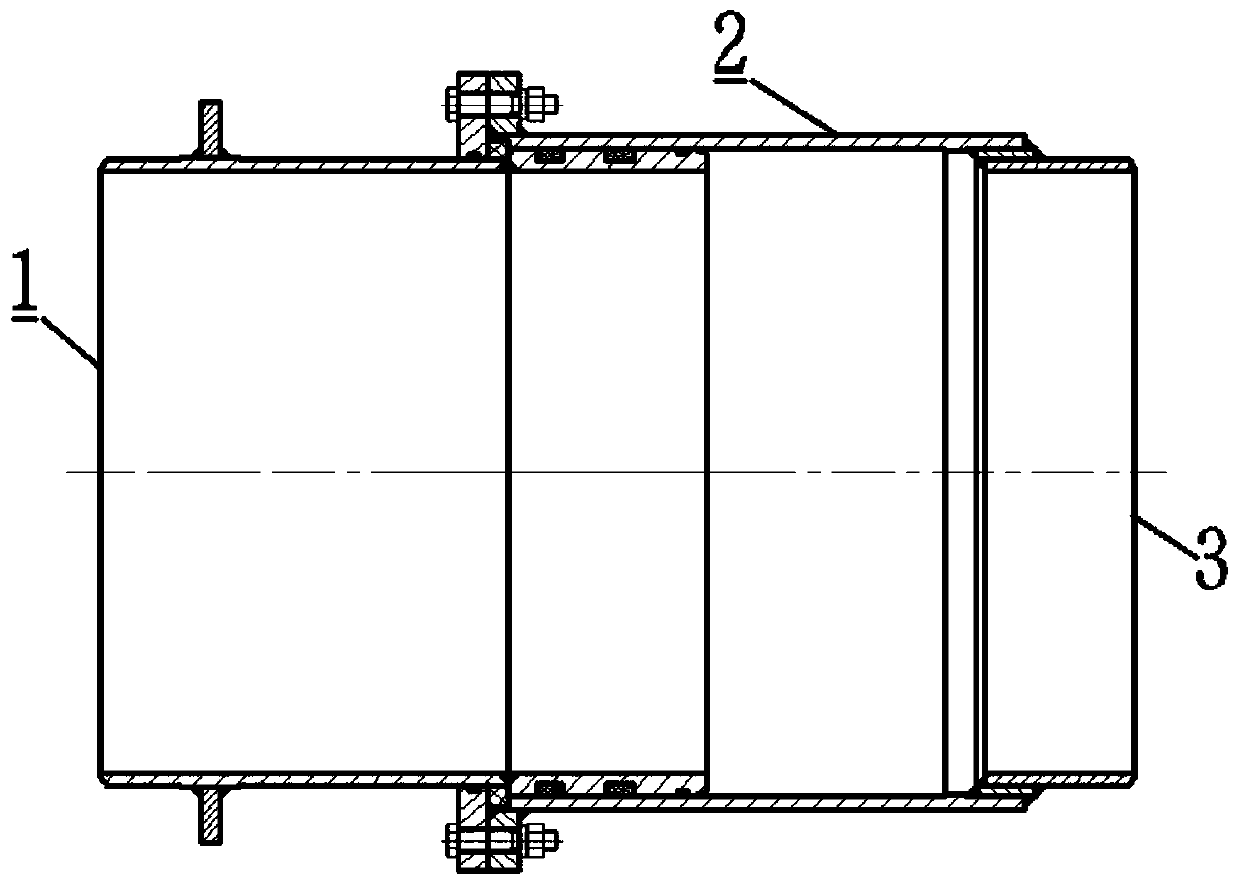

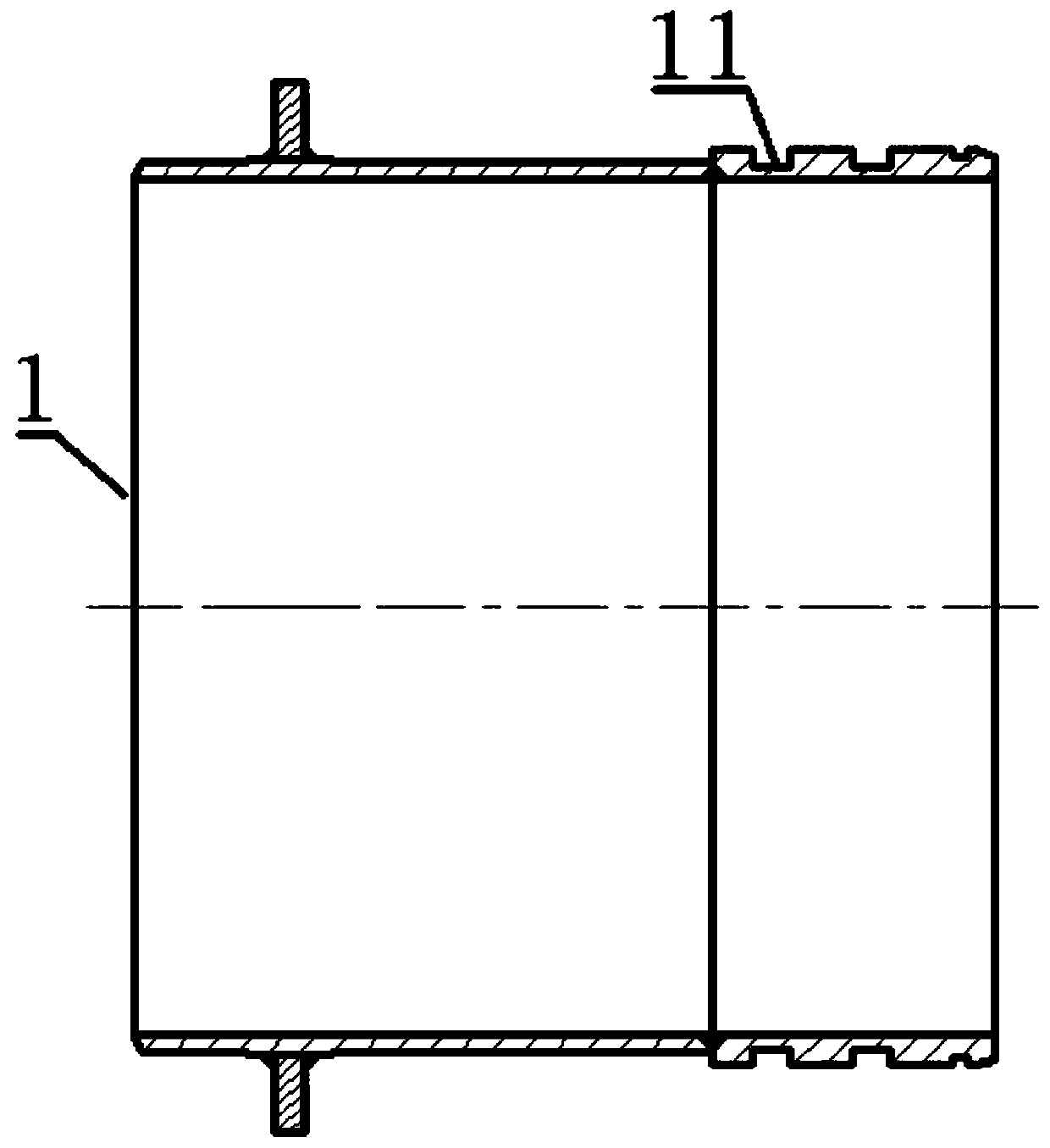

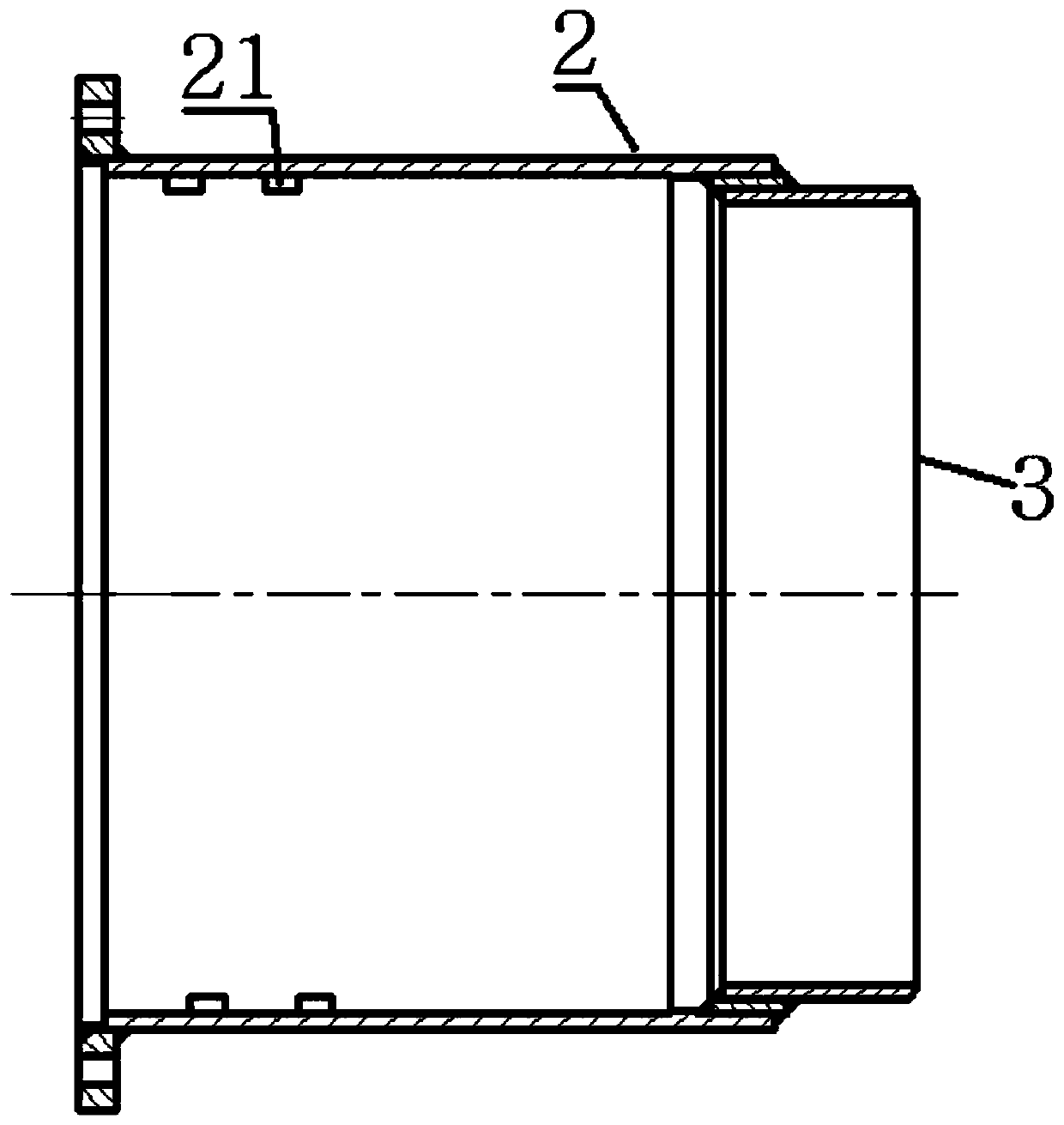

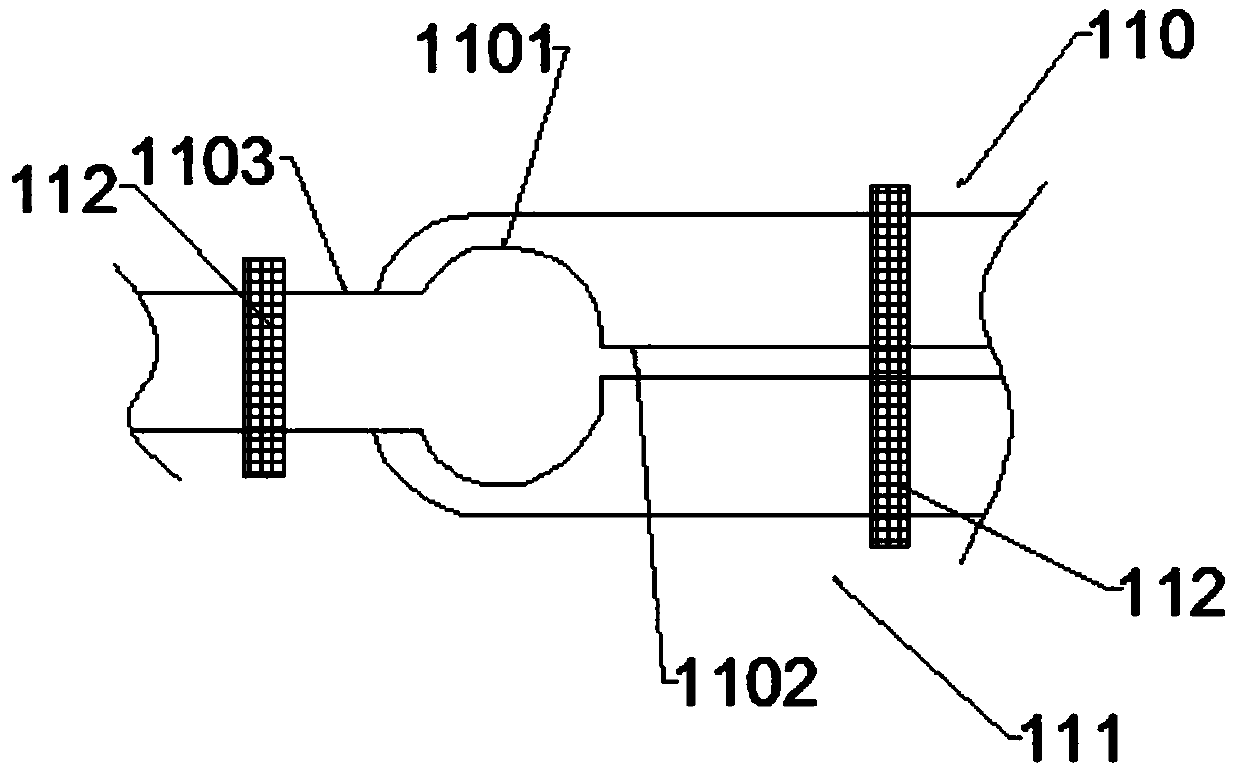

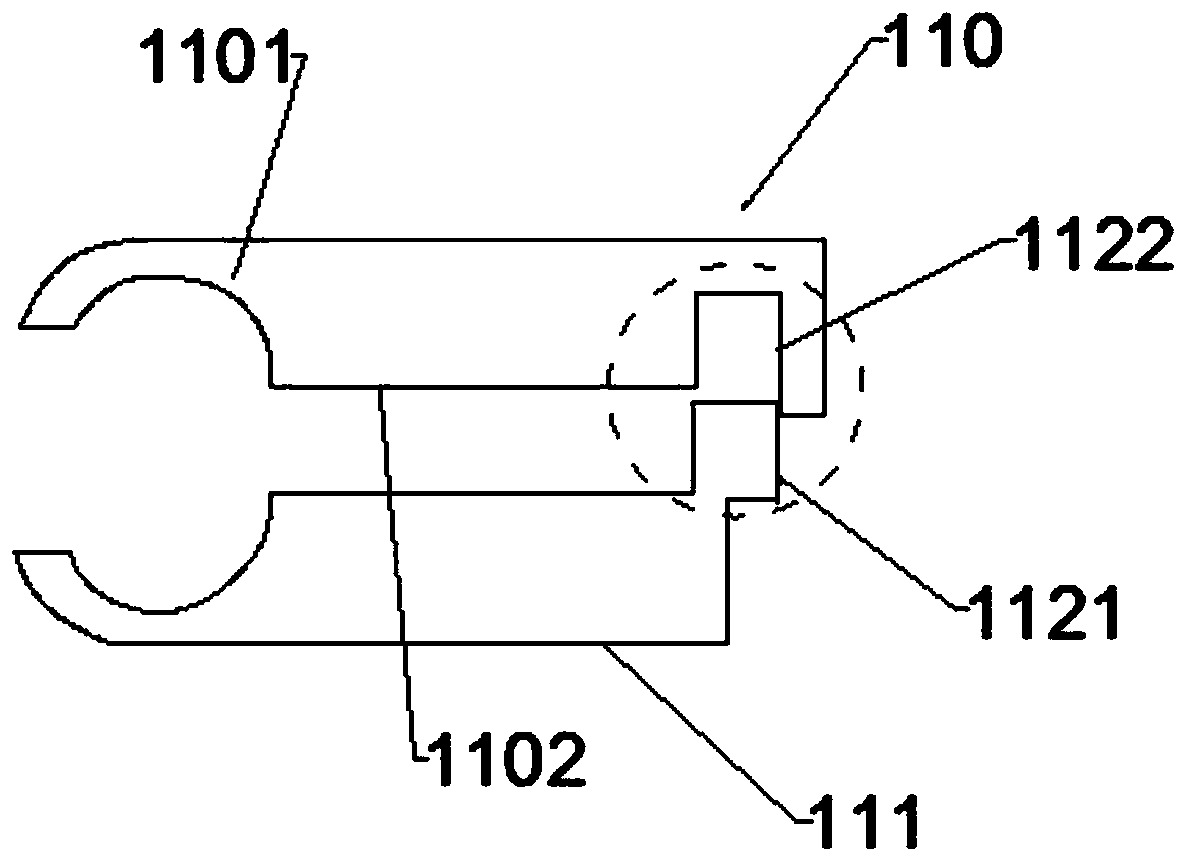

The invention relates to a sealing mechanism preventing gas exchange. The sealing mechanism comprises a stress block (3), a pressing block (4) and a compressing mechanism (5), wherein the stress block (3) is connected with a fixed part (1) and is in clearance fit with a rotating part (2); the pressing block (4) is in clearance fit with the rotating part (2) in a rotating mode; the compressing mechanism (5) is fixedly connected with the rotating part (2); the pressing block (4) presses the stress block (3) through the compressing mechanism; the stress block (3) is provided with a first sealing strip (3c); a second sealing strip (4e) is placed in a cavity (4d) of the pressing block (4); a first gap (2a) formed between the pressing block (4) and the outer wall surface of the rotating part (4) is sealed through the second sealing strip (4e); a threaded rod (7a) of a compressing screw (7) of the compressing mechanism (5) applies pressure to a force applying surface (4a2) of the pressing block (4), and the pressing block (4) compresses the first sealing strip (3c) of the stress block (3) through a first pressing surface (4a2) of a compressing surface (4a1) so that a second gap (8) formed between the pressing block (4) and the stress block (3) can be sealed. The sealing function is achieved through the simple mechanical sealing mechanism, gas exchange through the gap formed between the fixed part and the rotating part is prevented, in this way, external gas is prevented from entering the rotating part through the gap, and meanwhile gas inside the rotating part is prevented from leaking outwards through the gap.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

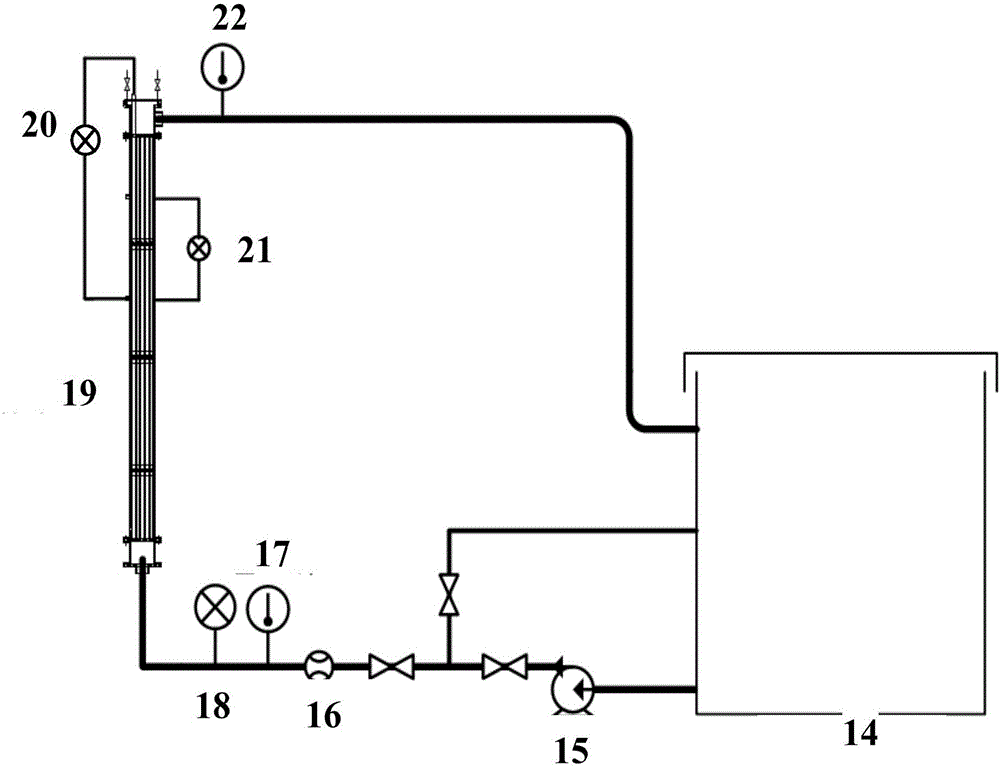

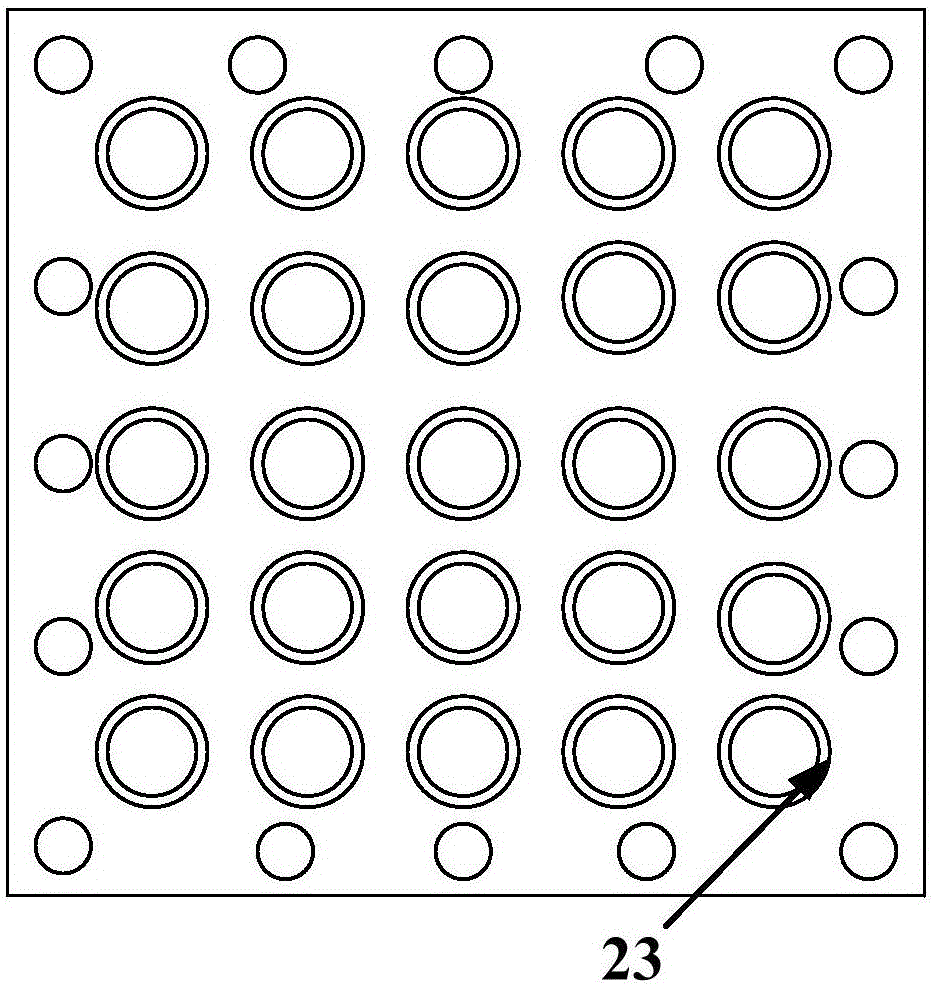

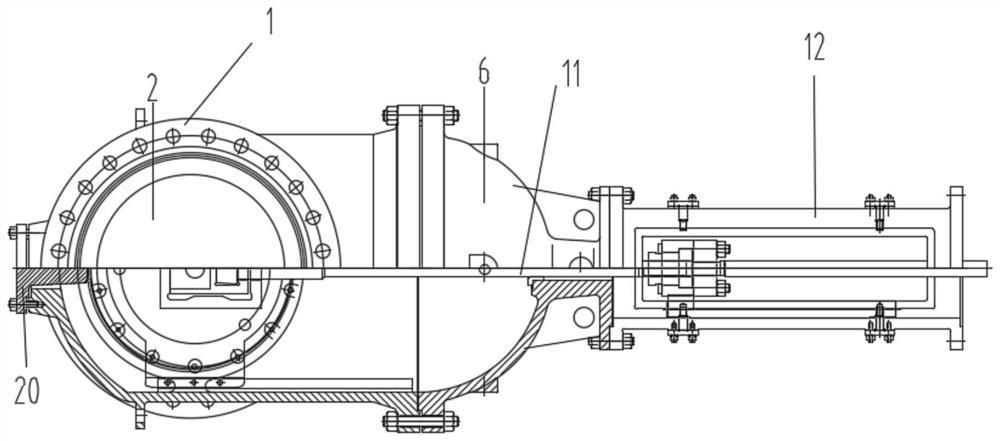

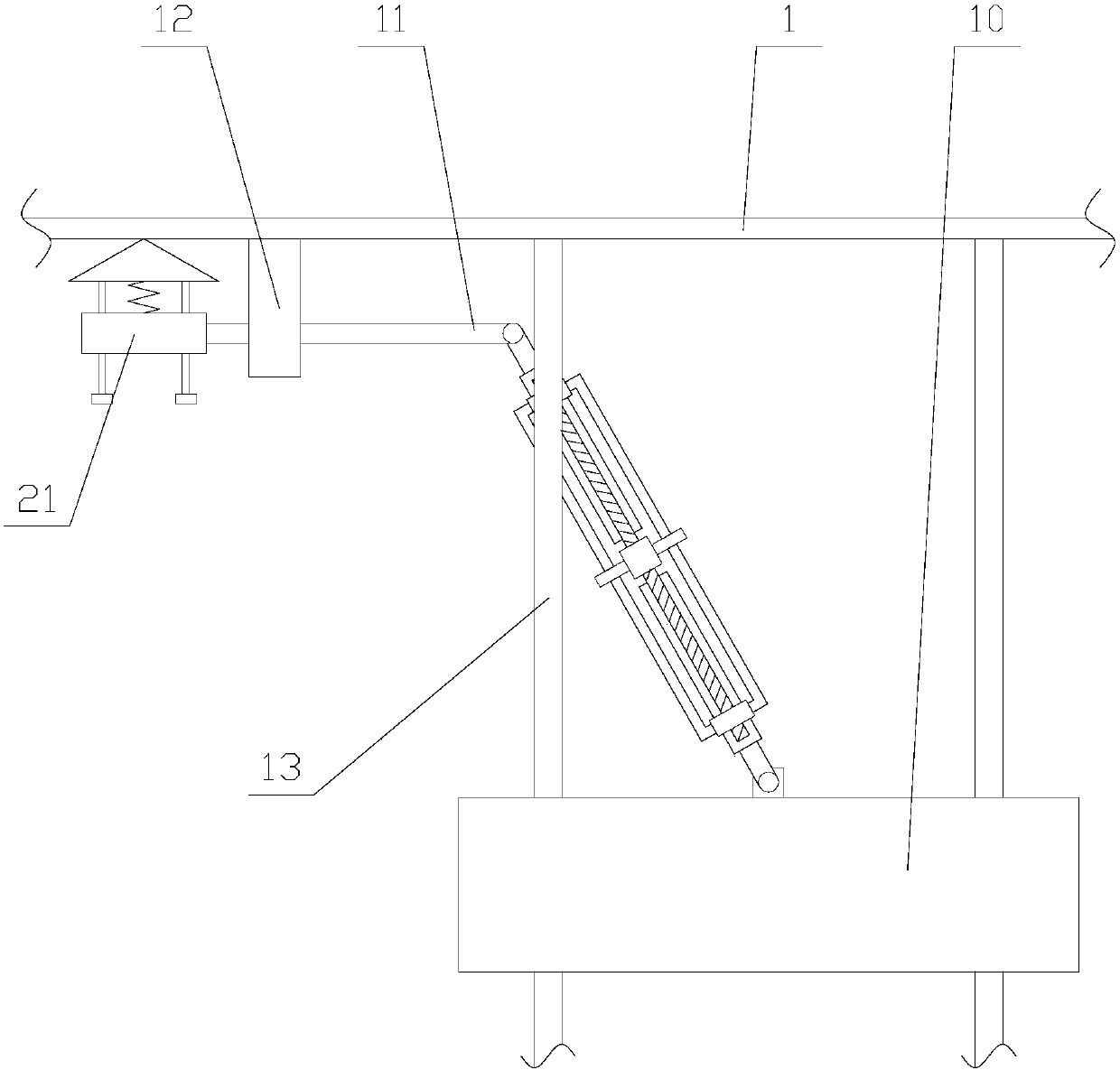

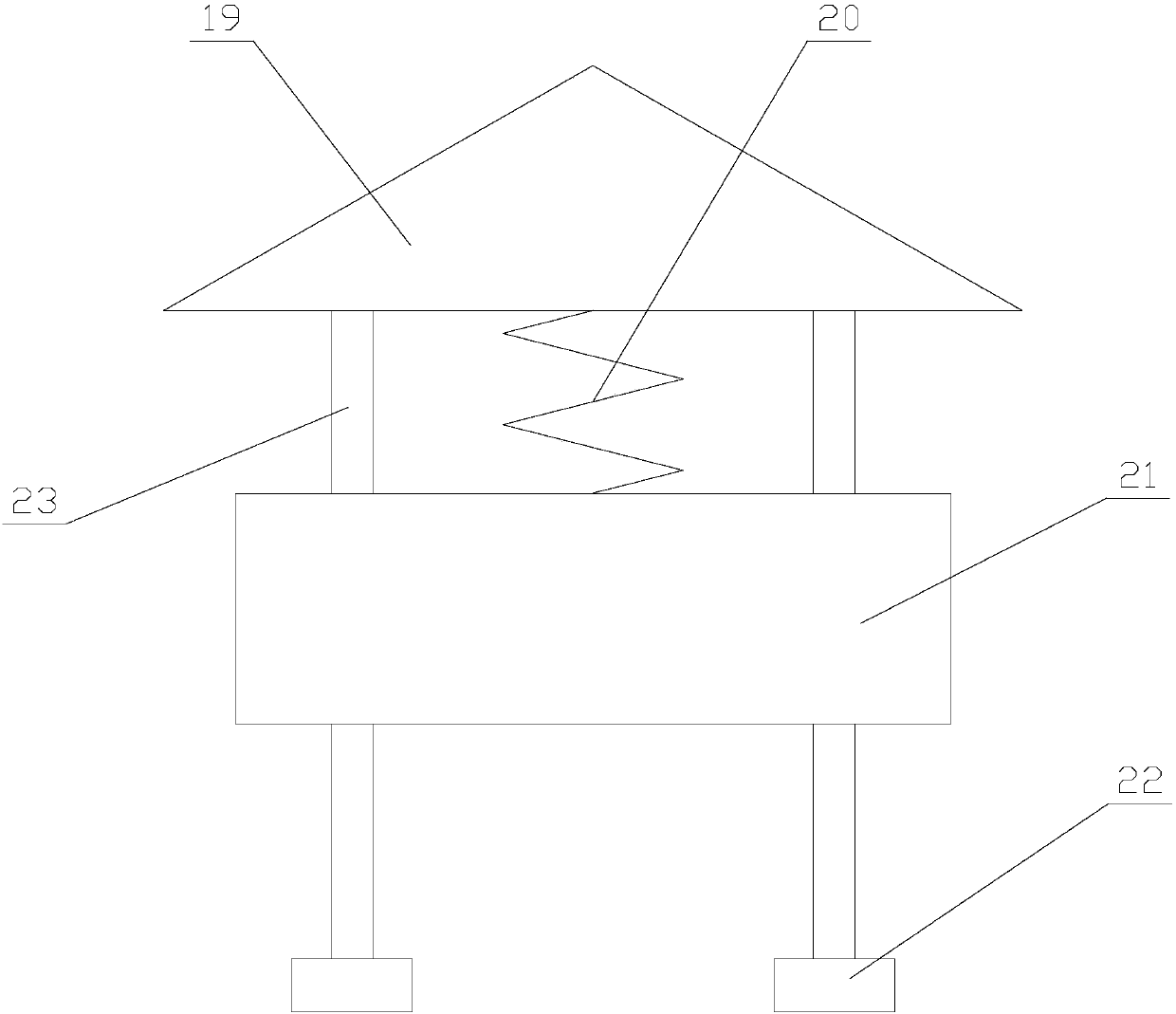

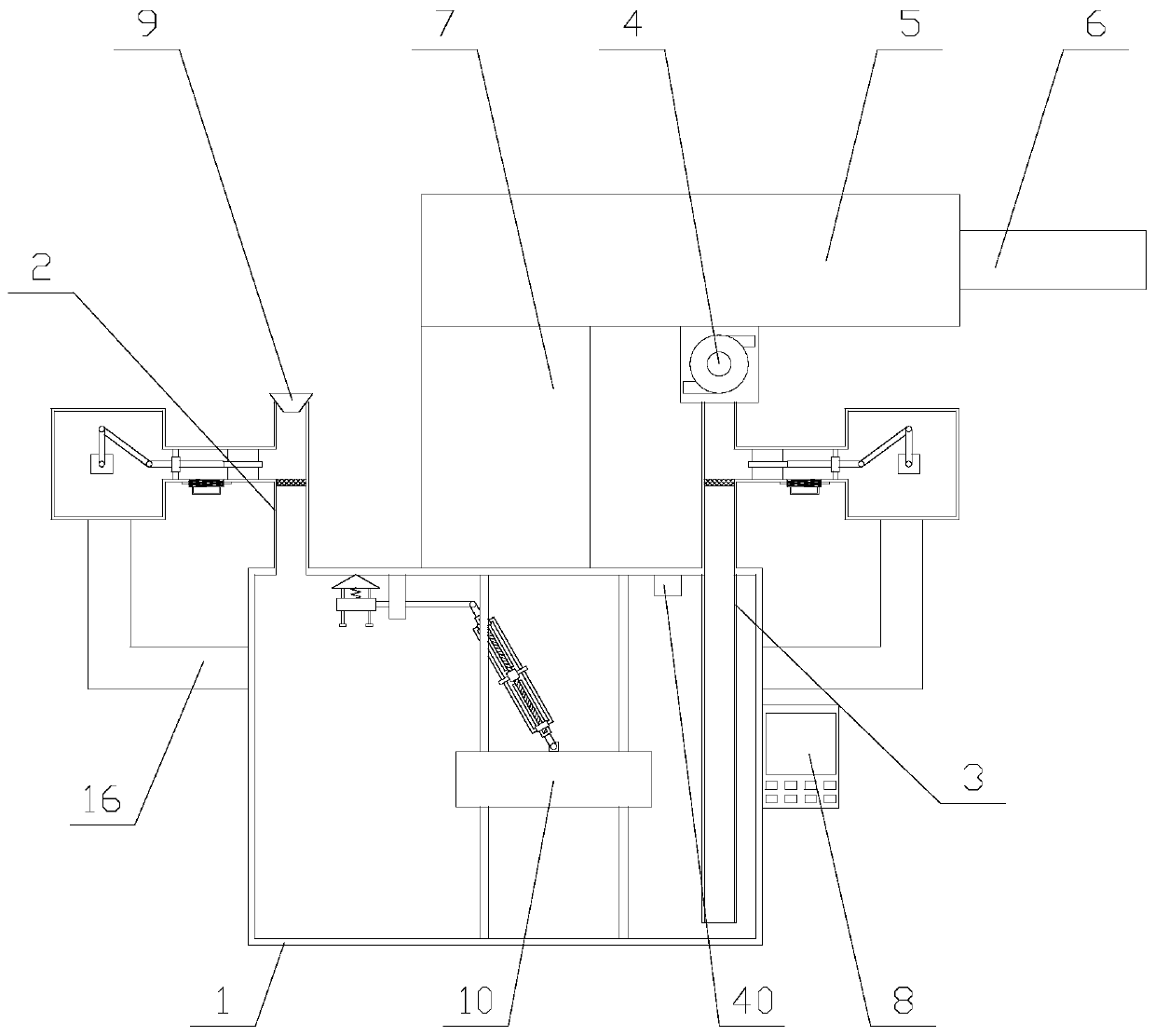

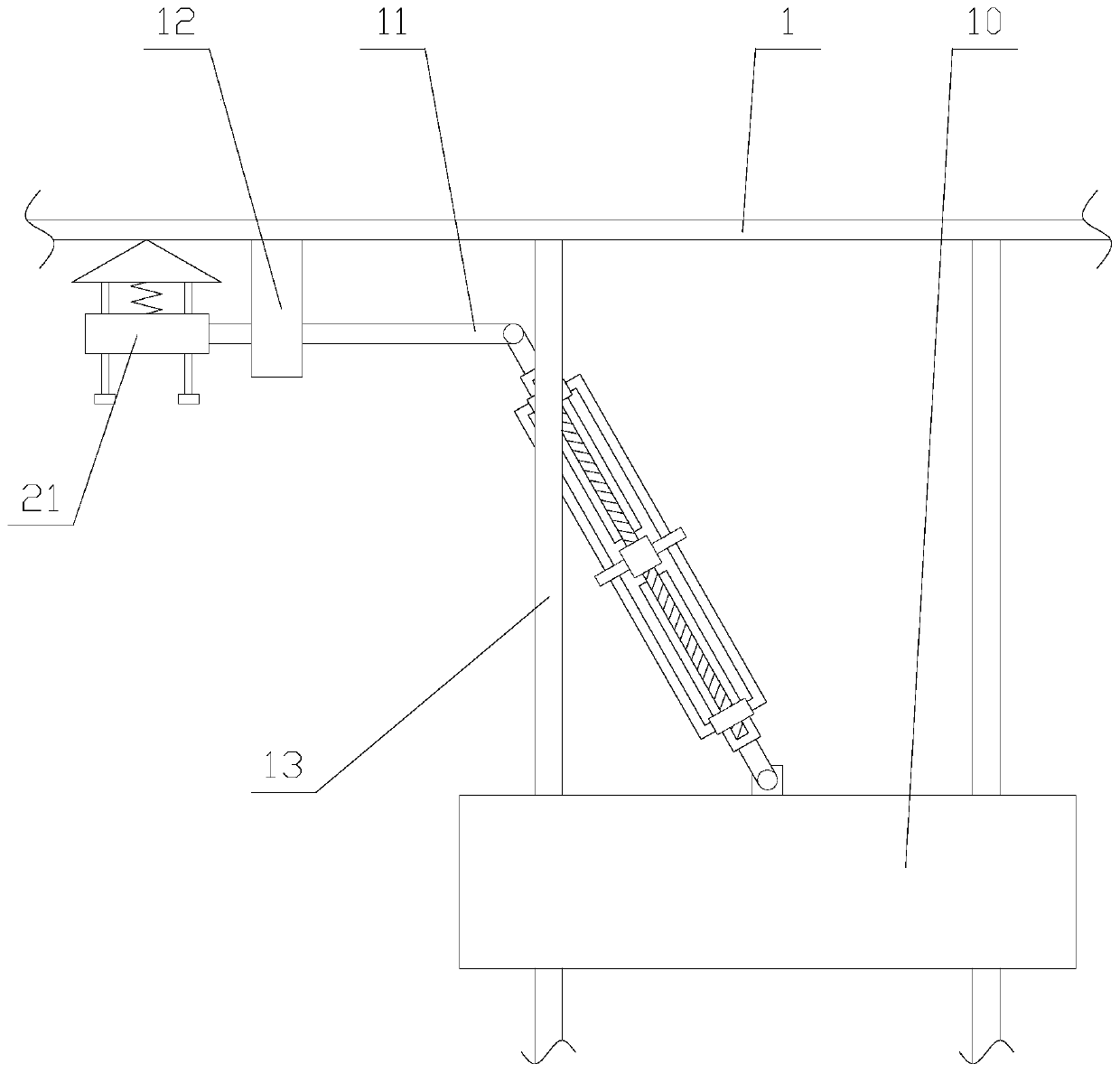

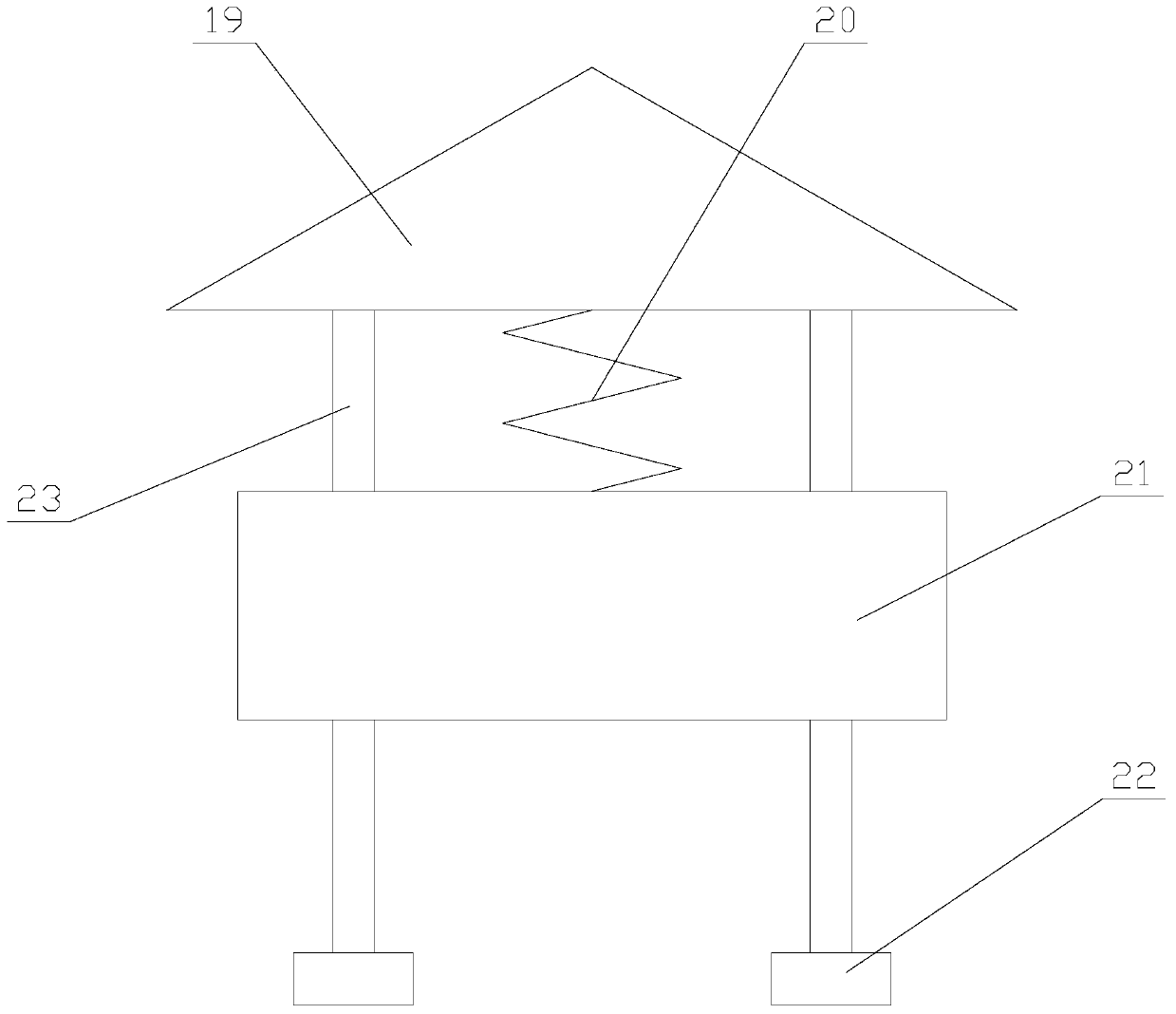

Rod bundle channel flow pressure measuring test device

ActiveCN106683722AEasy to moveSmooth rotationNuclear energy generationNuclear monitoringRotary stageCoupling

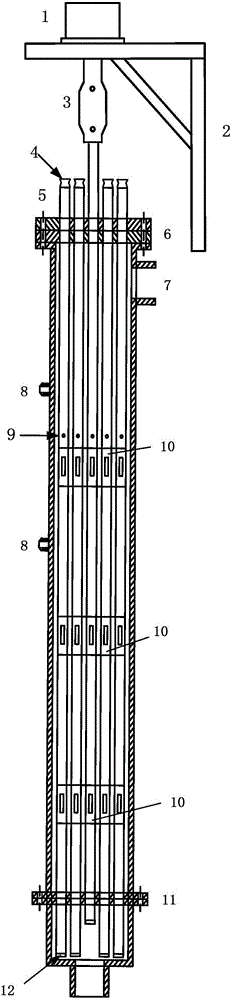

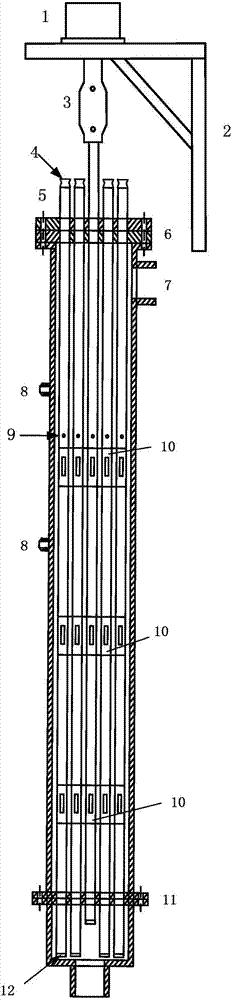

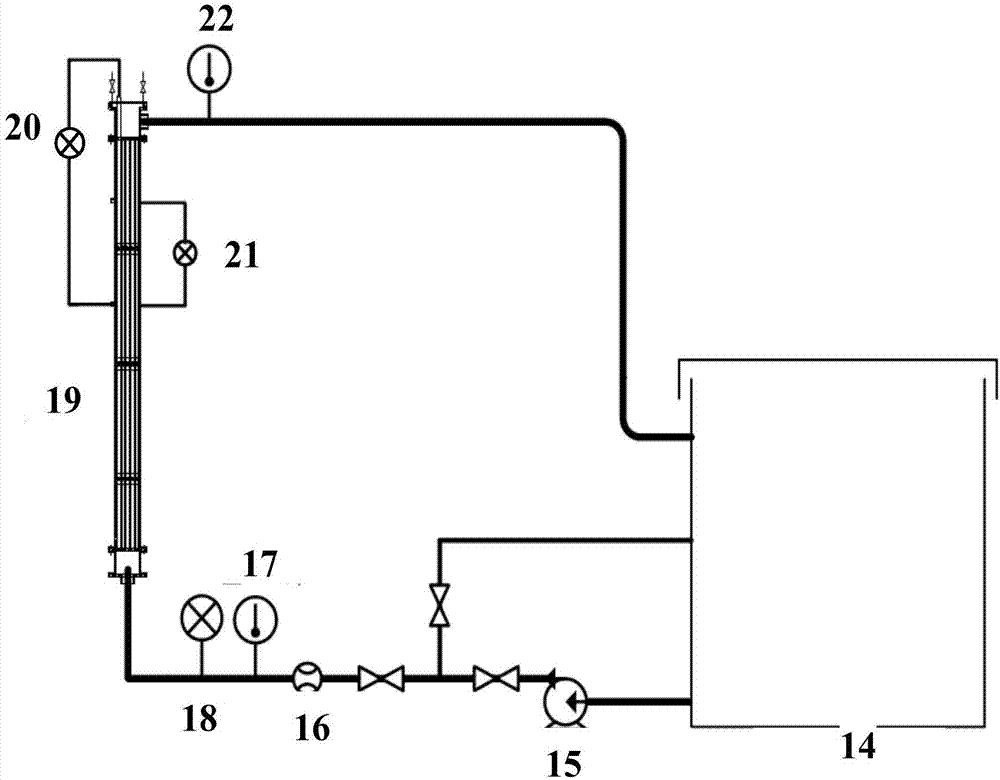

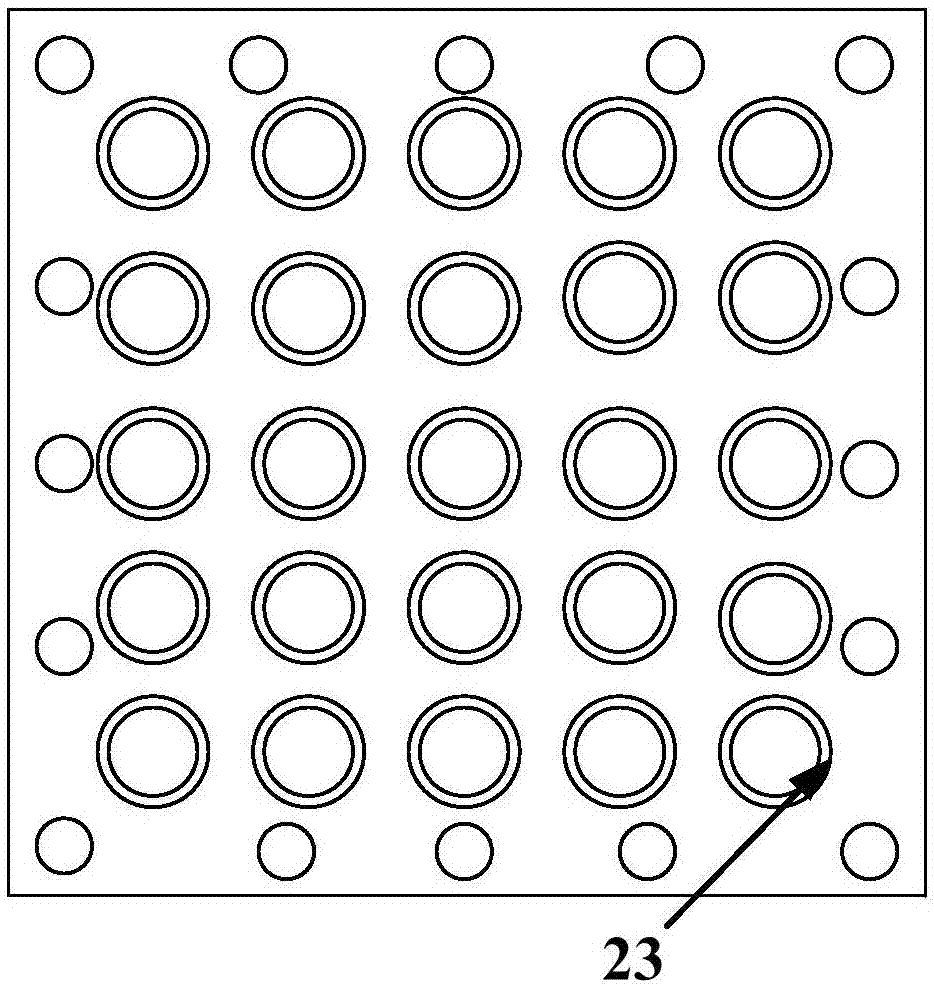

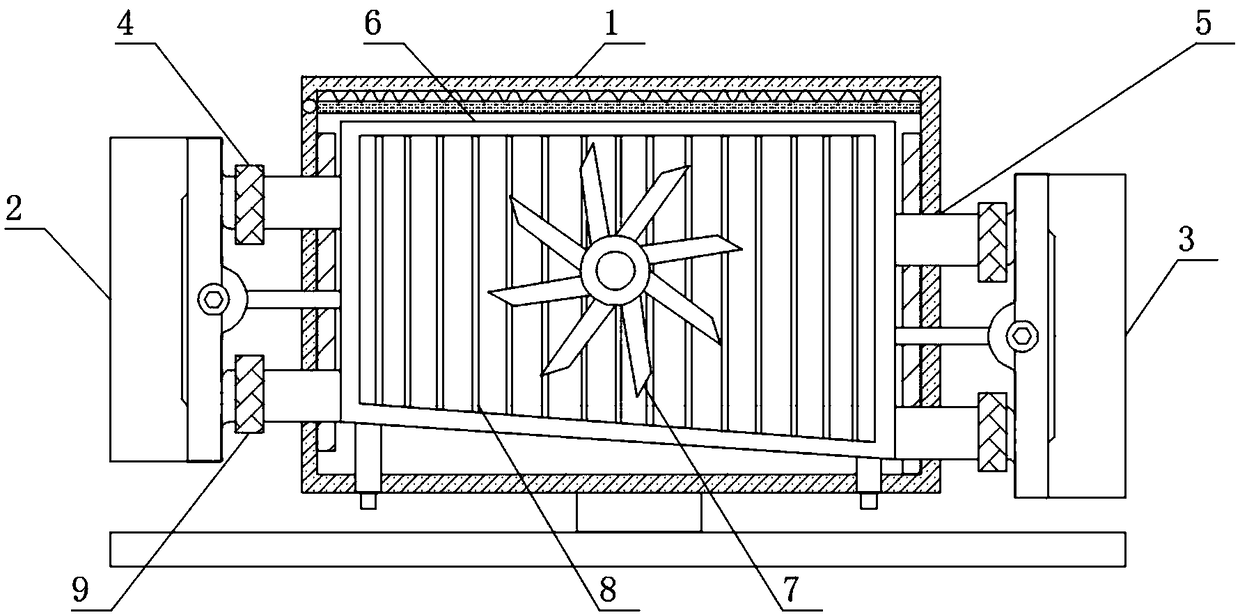

The invention provides a rod bundle channel flow pressure measuring test device, which comprises a water storage tank, a pressure measuring body, and a centrifugal pump, a regulating valve and a thermometer sequentially connected with the water storage tank through a pipeline, wherein the pressure measuring body comprises a rod bundle channel barrel, a rod bundle channel formed by rod bundles arranged in the rod bundle channel barrel; the upper ends of the rod bundles are connected with a high-accuracy rotating disk arranged on a rotating table support through a coupler; two body pressure ports formed up and down are formed in the rod bundle channel barrel; a pressure guiding port is formed in each rod bundle of the rod bundle channel; a sealing rubber plug is arranged at the lower end of each rod bundle; a fast adapter is arranged at the upper end of each rod bundle; pressure difference transmitters are respectively arranged between each pressure guiding port and each fast adapter as well as between the two body pressure ports. The rod bundle channel flow pressure measuring test device provided by the invention can simulate single-phase flow in a reactor rod bundle channel so as to research a resistance characteristic of the rod bundle channel, and is simple in structure, low in cost, accurate and convenient to acquire data, and wide in research working condition range.

Owner:HARBIN ENG UNIV

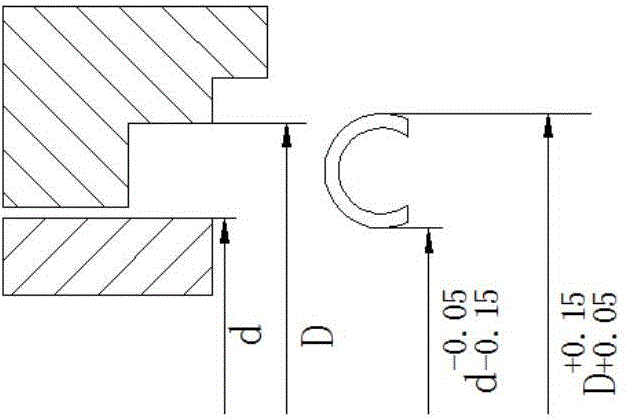

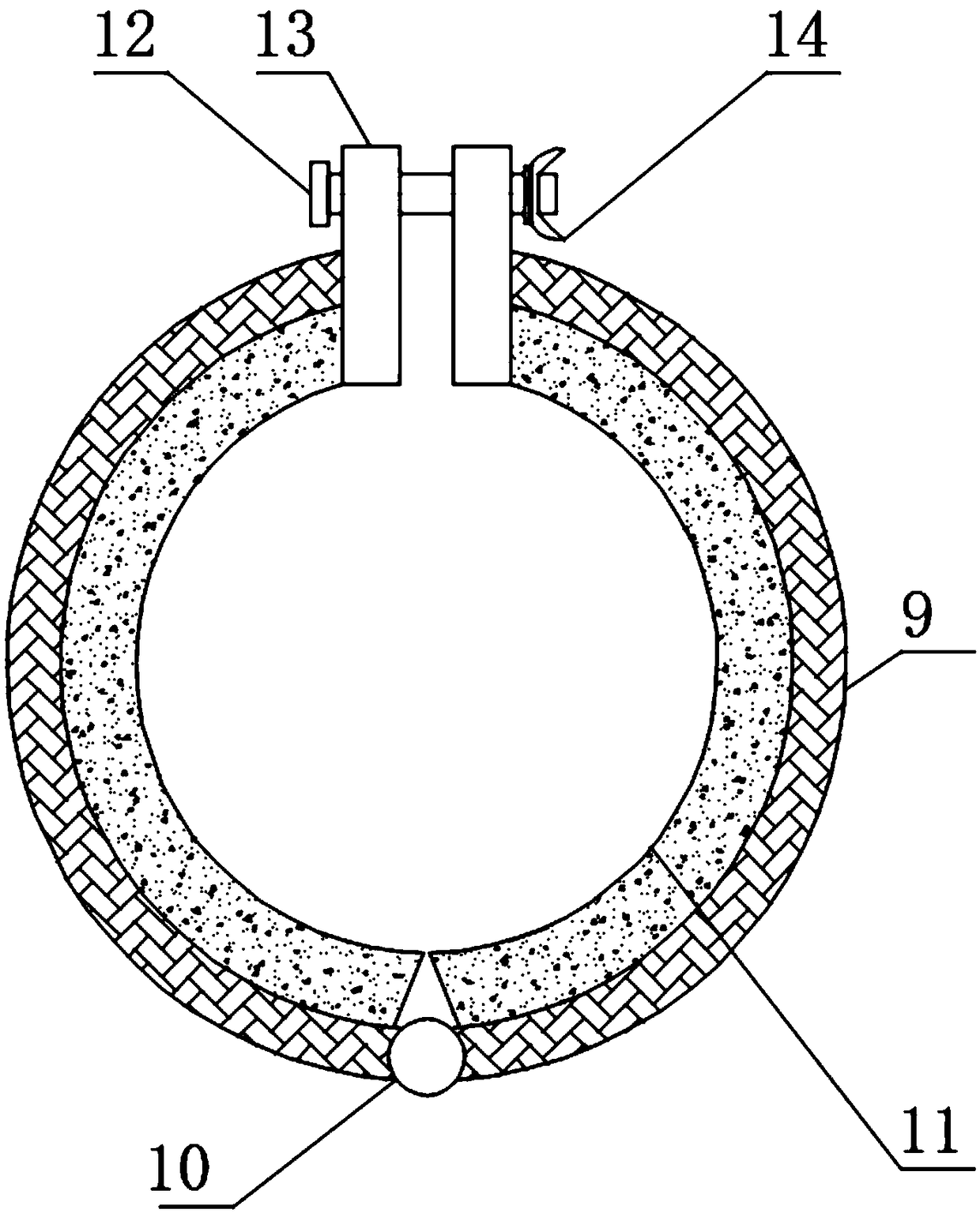

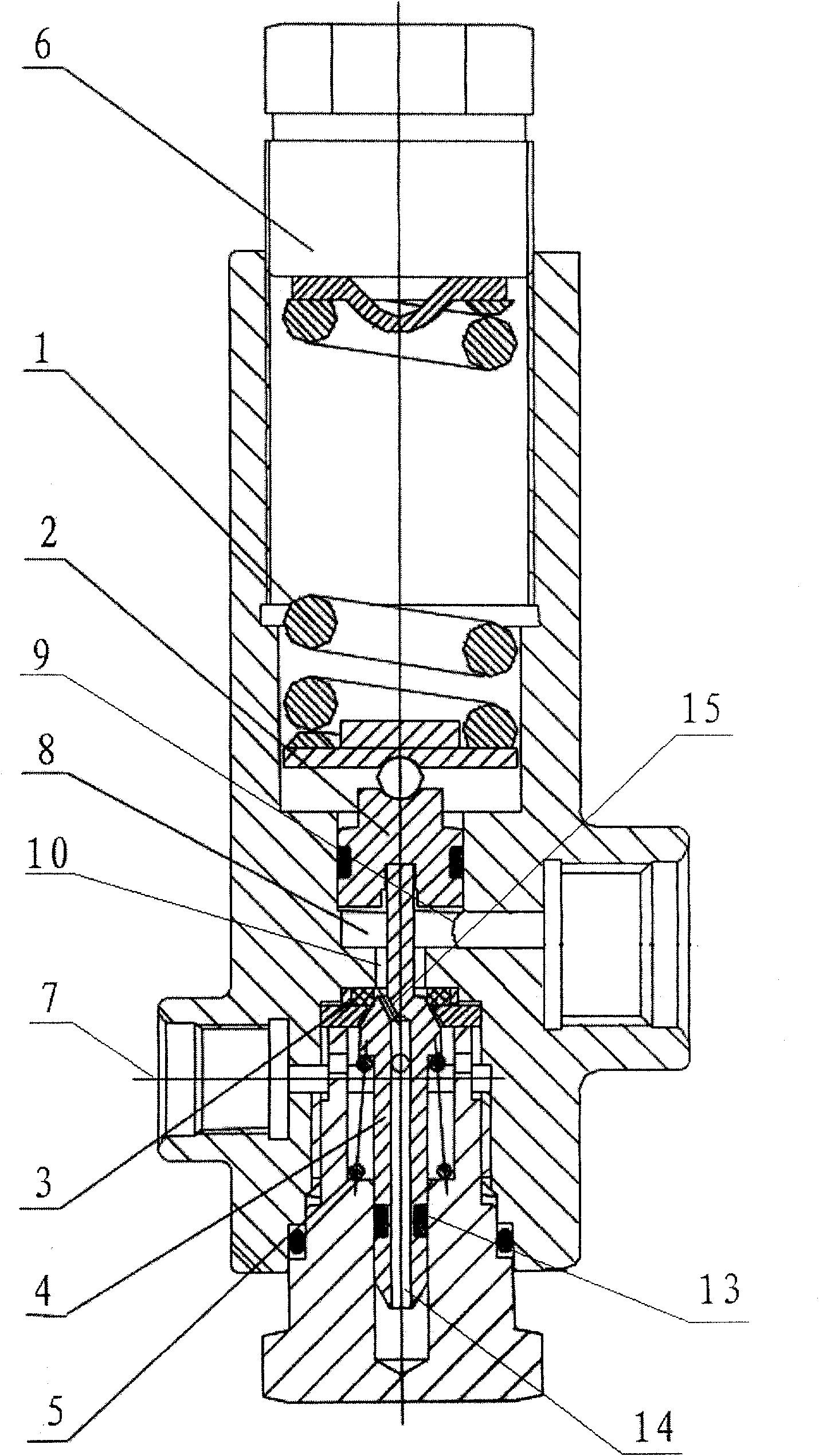

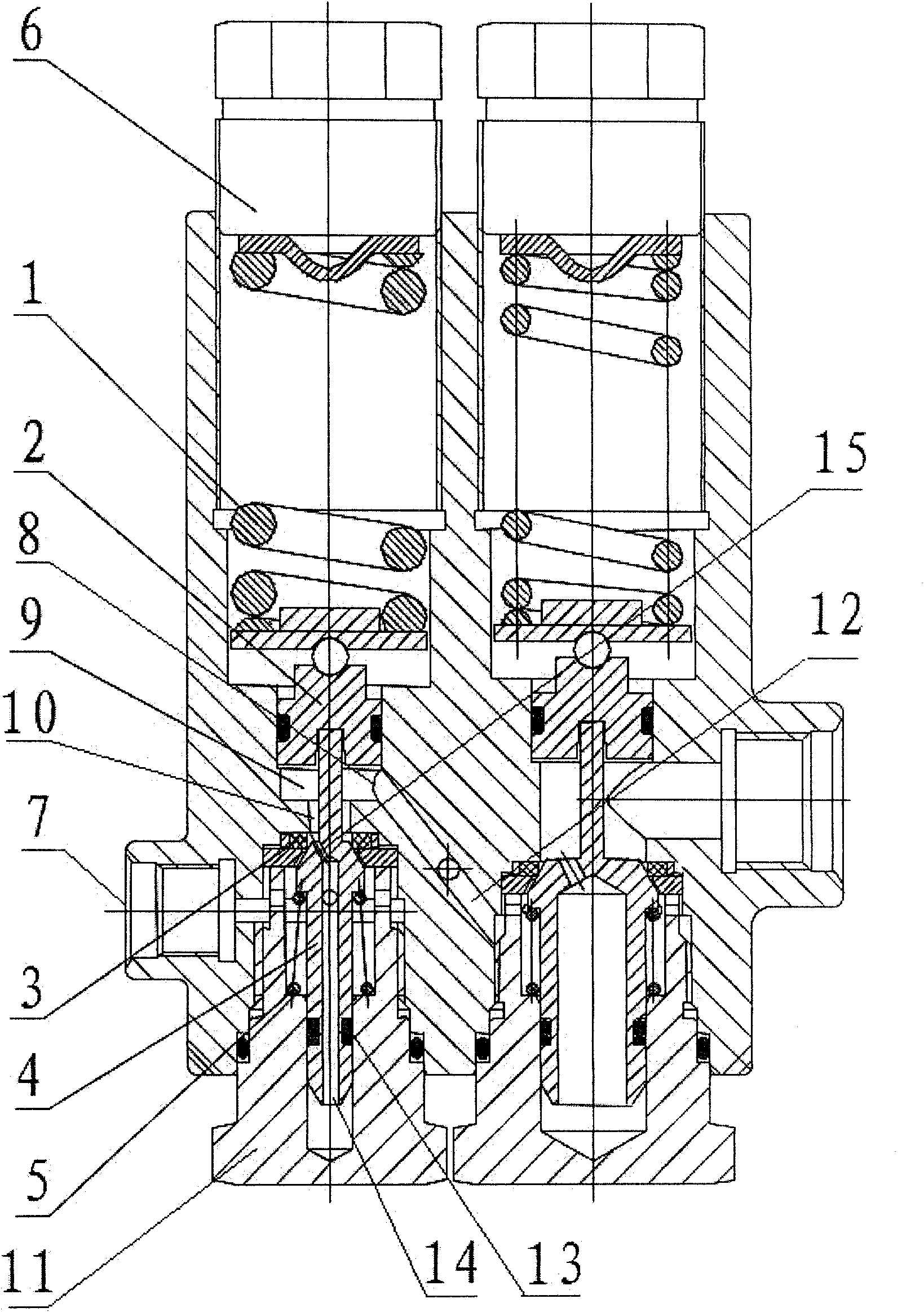

Rotary joint

The invention relates to a rotary joint and belongs to the technical field of heat power pipe network matching. The joint comprises an outer pipe, an inner pipe and a gland, wherein an inner convex ring is arranged inside the outer pipe, an outer convex ring is arranged outside the inner pipe, the inner convex ring and the outer convex ring are respectively provided with V-shaped grooves of which openings are opposite, and obliquely-arranged cylindrical rollers are mounted inside the V-shaped grooves; one end of the inner convex ring adopts an expanding section with an annular space, and a C-shaped elastic metal sealing ring is embedded into the annular space; a trapezoidal baffle ring with an inclined plane at one end is mounted at the other end of the inner convex ring, the inner end of the gland adopts an inclined plane which is opposite to the inclining direction of the trapezoidal baffle ring, and a graphite filling material sealing ring is mounted between the trapezoidal baffle ring and the gland. After the adoption of the invention, the C-shaped elastic metal sealing ring and the graphite filling material sealing ring form high-temperature resistant and high-voltage resistant double sealing, the arranged direction of a bearing and the trapezoidal cross section graphite filling material sealing ring form a reasonable force bearing system. Therefore, the rotary joint provided by the invention has remarkable advantages that reliable sealing under high-temperature and high-voltage conditions is kept while free rotation can be ensured.

Owner:AEROSUN CORP

Atomospheric pressure glow discharge plasma reactor possessing rotary relix electrode

InactiveCN1695792AImprove work efficiencySpeed up the flowHydrocarbon by hydrocarbon condensationEnergy based chemical/physical/physico-chemical processesElectric fieldMetal cylinder

An atmospheric glow-discharge plasma reactor with rotary spiral electrode for preparing C2 hydrocarbon from methane features that its rotary spiral electrode is made up by fixing the spiral metallic band with toothed edge to a cylindrical metal column, and the electrically insulated top end of said electrode is linked to sealing unit. Its advantages are high uniformity of plasma distribution and high reaction efficiency.

Owner:DALIAN UNIV OF TECH

Steel stranded rubber support and production method thereof

ActiveCN102425106AEasy to installPrevent voltage biasBridge structural detailsElastomerStructural engineering

The invention belongs to the technical field of bridge supports, and discloses a steel stranded rubber support and a production method thereof. The steel stranded rubber support is mainly technically characterized by comprising a convex spherical crown steel stranded support with a convex spherical surface and a concave spherical crown steel stranded support with a concave spherical surface, wherein the convex spherical crown steel stranded support and the concave spherical crown steel stranded support are coated or partly coated by an elastomer. The steel stranded rubber support provided by the invention is large in corner so as to be capable of self-adapting to a corner of a girder body and to effectively prevent biasing of plate type rubber supports. And the convex spherical crown steel stranded support and the concave spherical crown steel stranded support are coated or partly coated by the elastomer, therefore, the stress is not further applied to the peripheral rubber of the support and other elastomer protection layers, and good sealing performance and long service life are achieved. The steel stranded rubber support has the advantages of plate type supports and global supports, also has the advantages of convenience for installation and low cost, and is free of maintenance.

Owner:HEBEI BAOLI ENG EQUIP GRP CO LTD

Pre-deformed aircraft spoilers and droop panels designed to seal with flap in deflected state

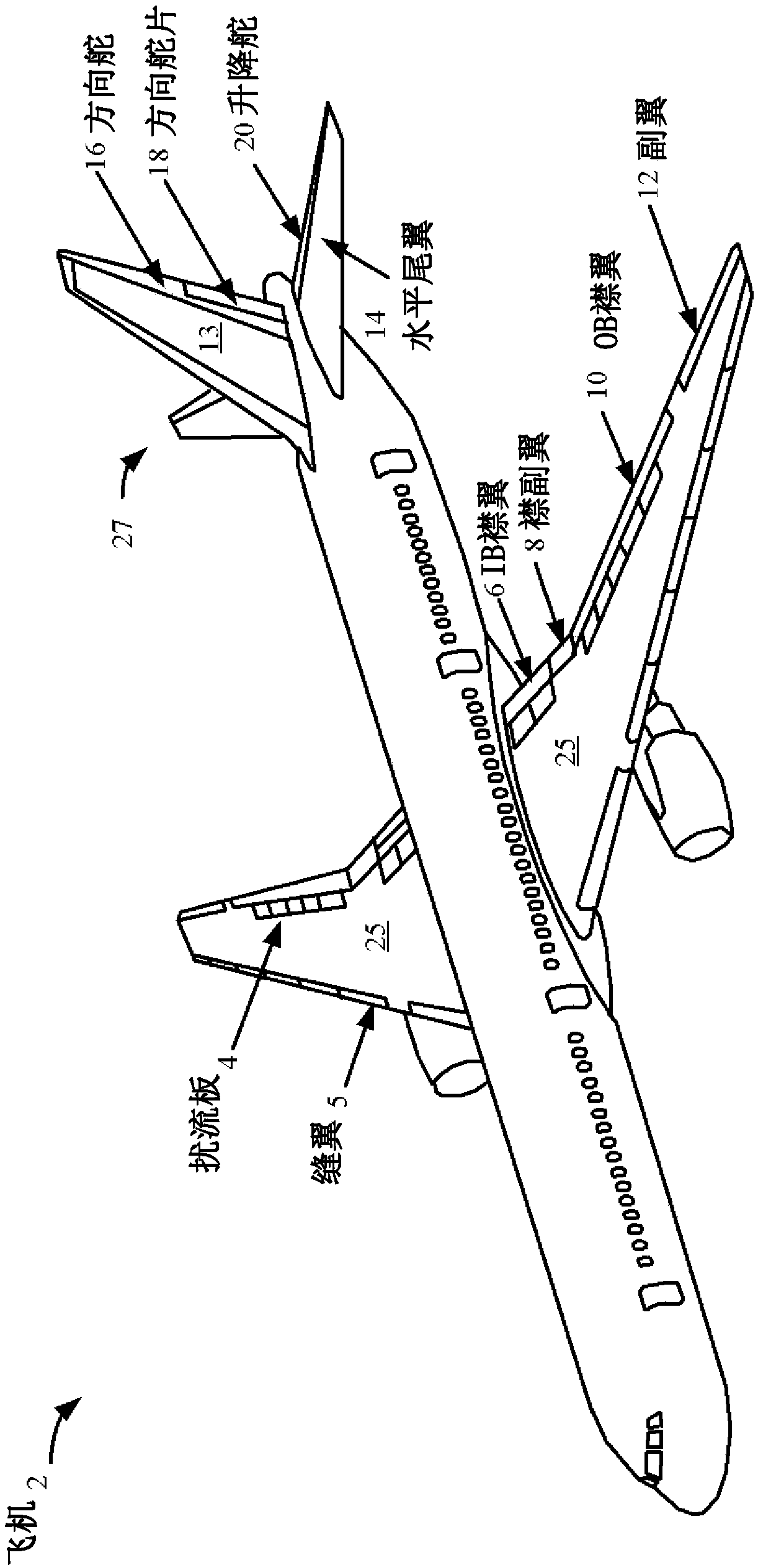

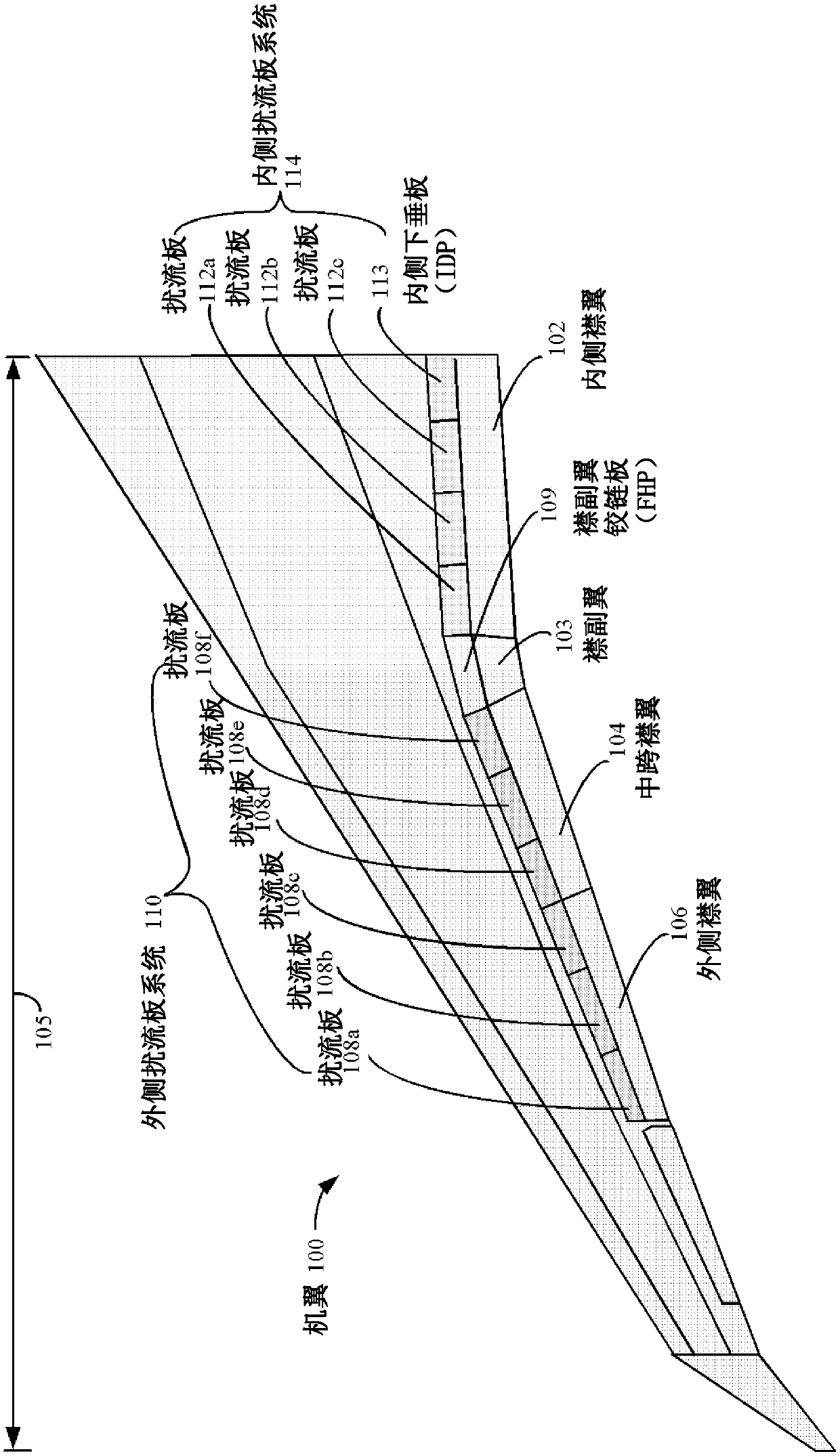

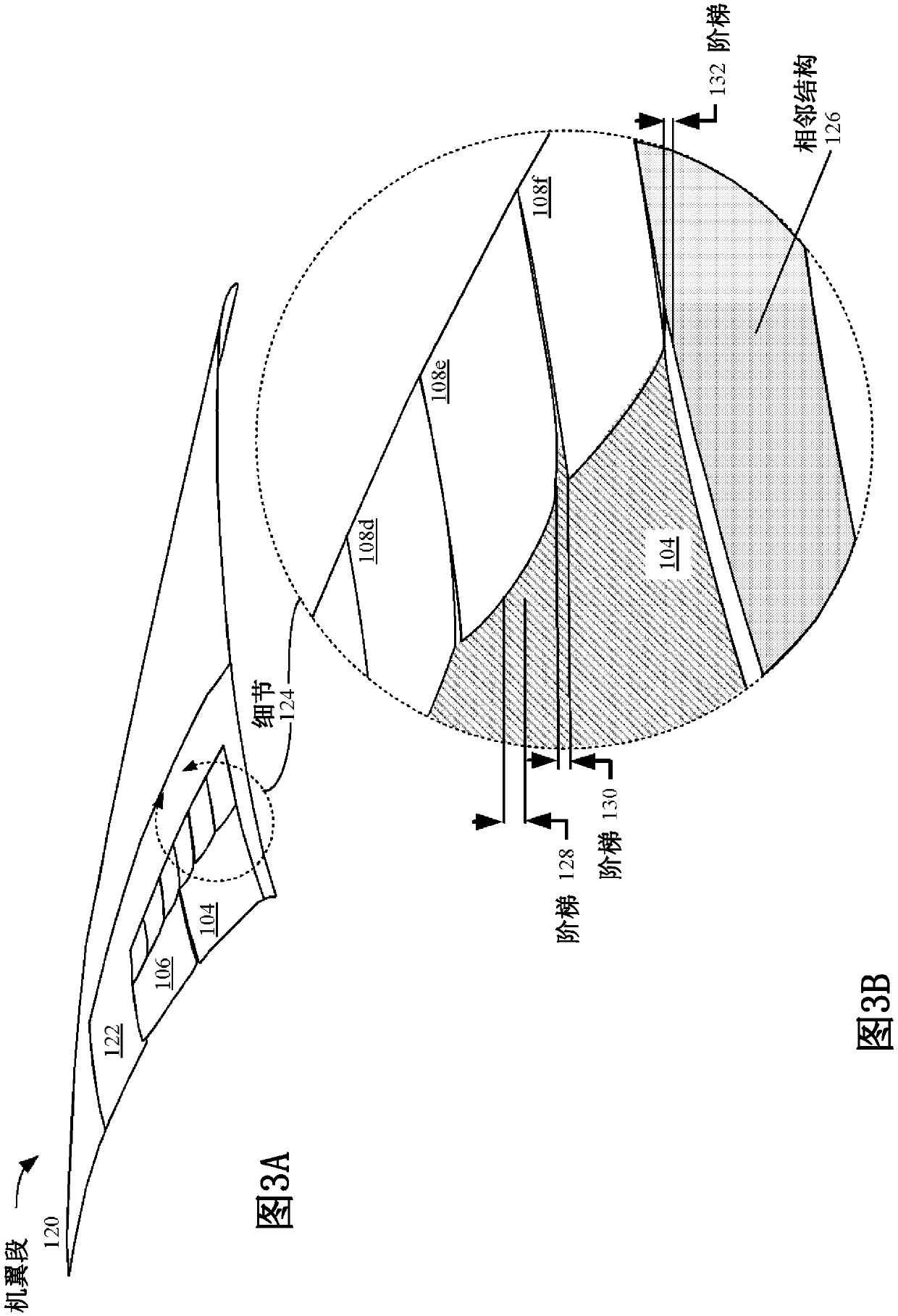

PendingCN109895992AImprove sealingFlexible geometry modificationAircraft controlWing lift eficiencyEngineeringTrailing edge

The application relates to pre-deformed aircraft spoilers and droop panels designed to seal with flap in deflected state, and relates to a methodology for designing spoilers or droop panels (113) andan aerodynamic systems including the designed spoilers or the designed droop panels 5. In one embodiment, the spoilers and the droop panels (113) can be deployed on a wing (100) with a flap system which provides for trailing edge variable camber (TEVC) system. During flight, the fixed portions of the wing (25, 100), the flaps, the spoilers and droop panels (113) can all deform. The spoilers or thedroop panels (113) 10 can each be pre-deformed to a first shape (152) on the ground such that in flight the spoilers or the droop panels (113) deform to a second shape (150) under aerodynamic loads.In the second shape (150), the spoilers or the droop panels (113) are configured to seal better against the flaps. The spoilers or the droop panels can be configured to seal to the flaps during all of15 the positions the flaps take as part of the TEVC system.

Owner:THE BOEING CO

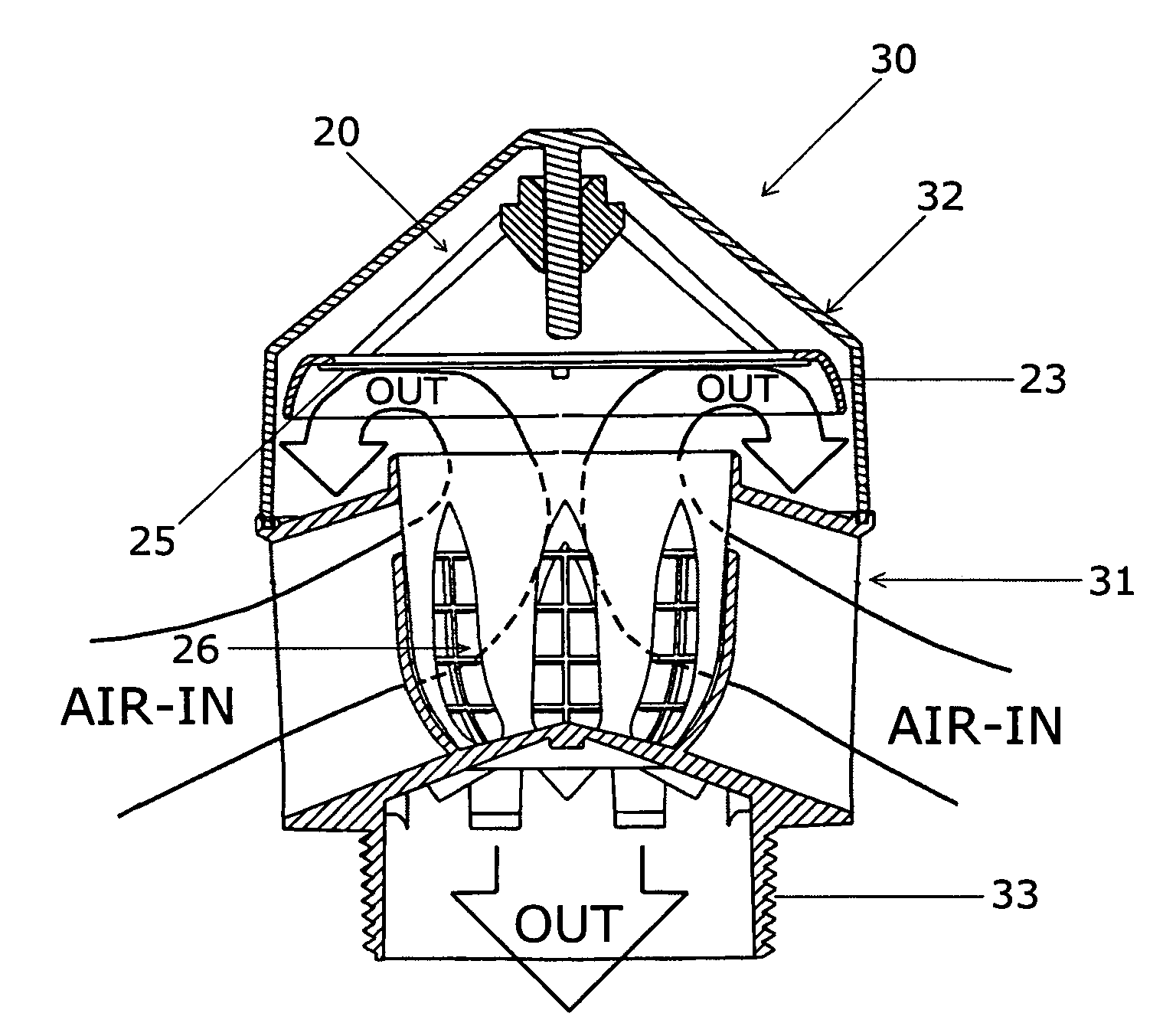

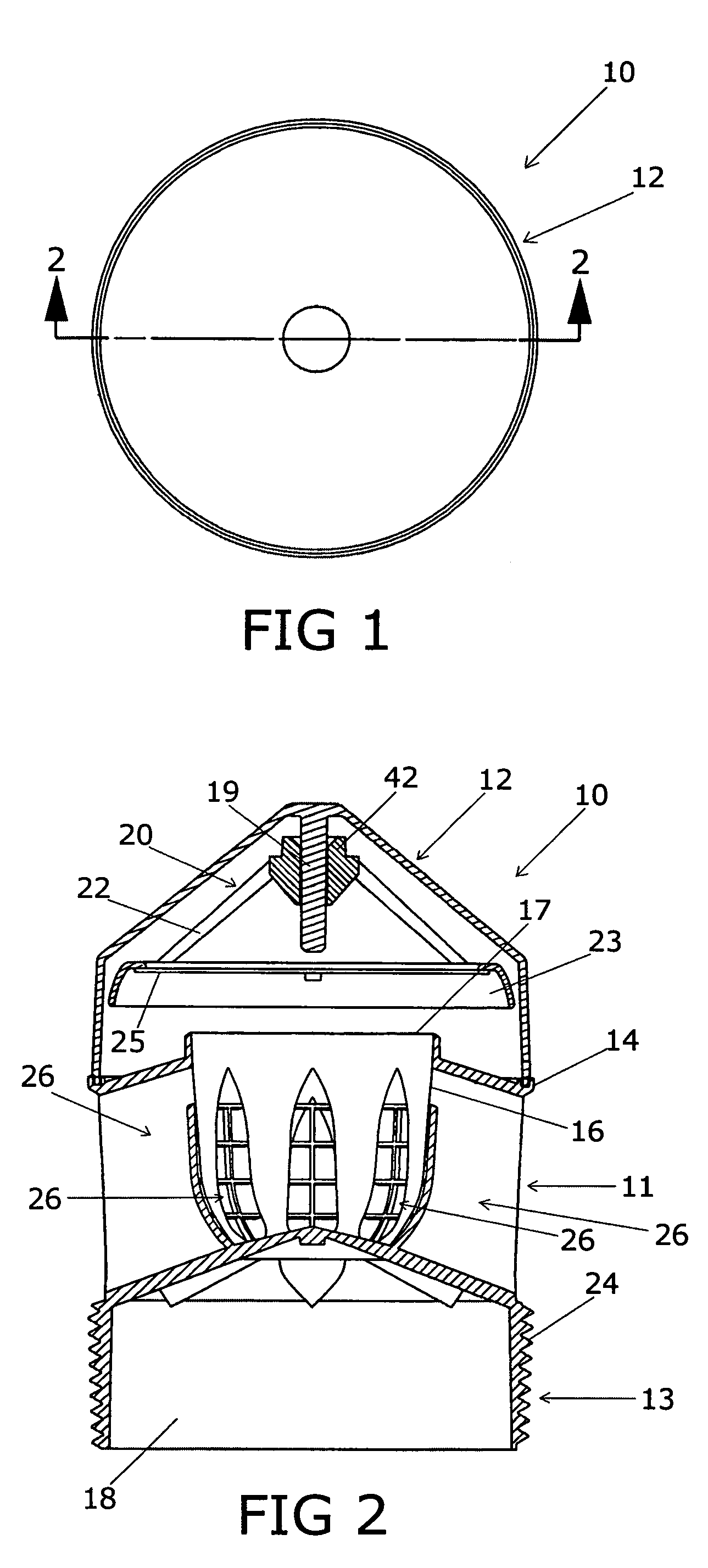

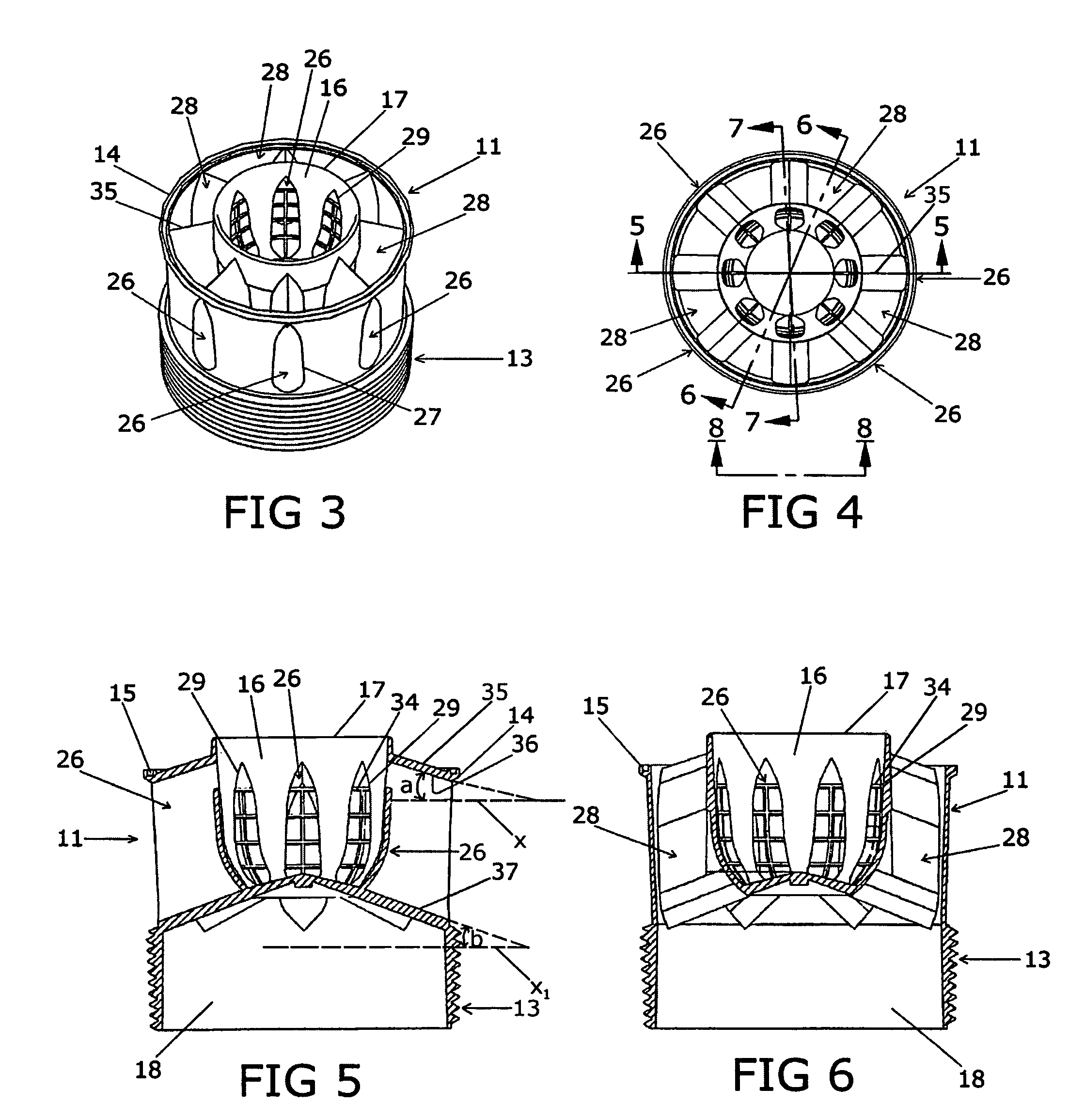

Air admittance valve assembly

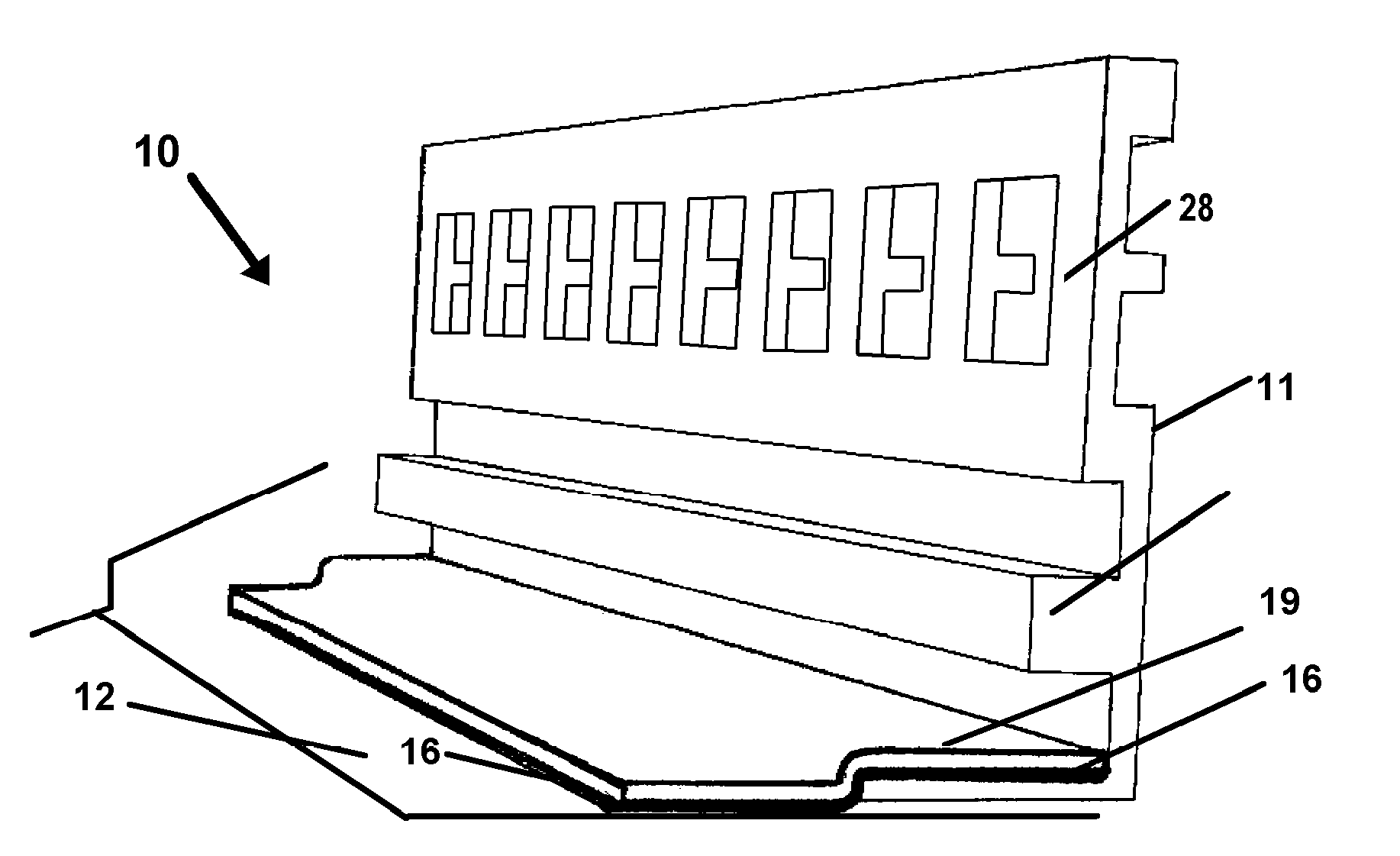

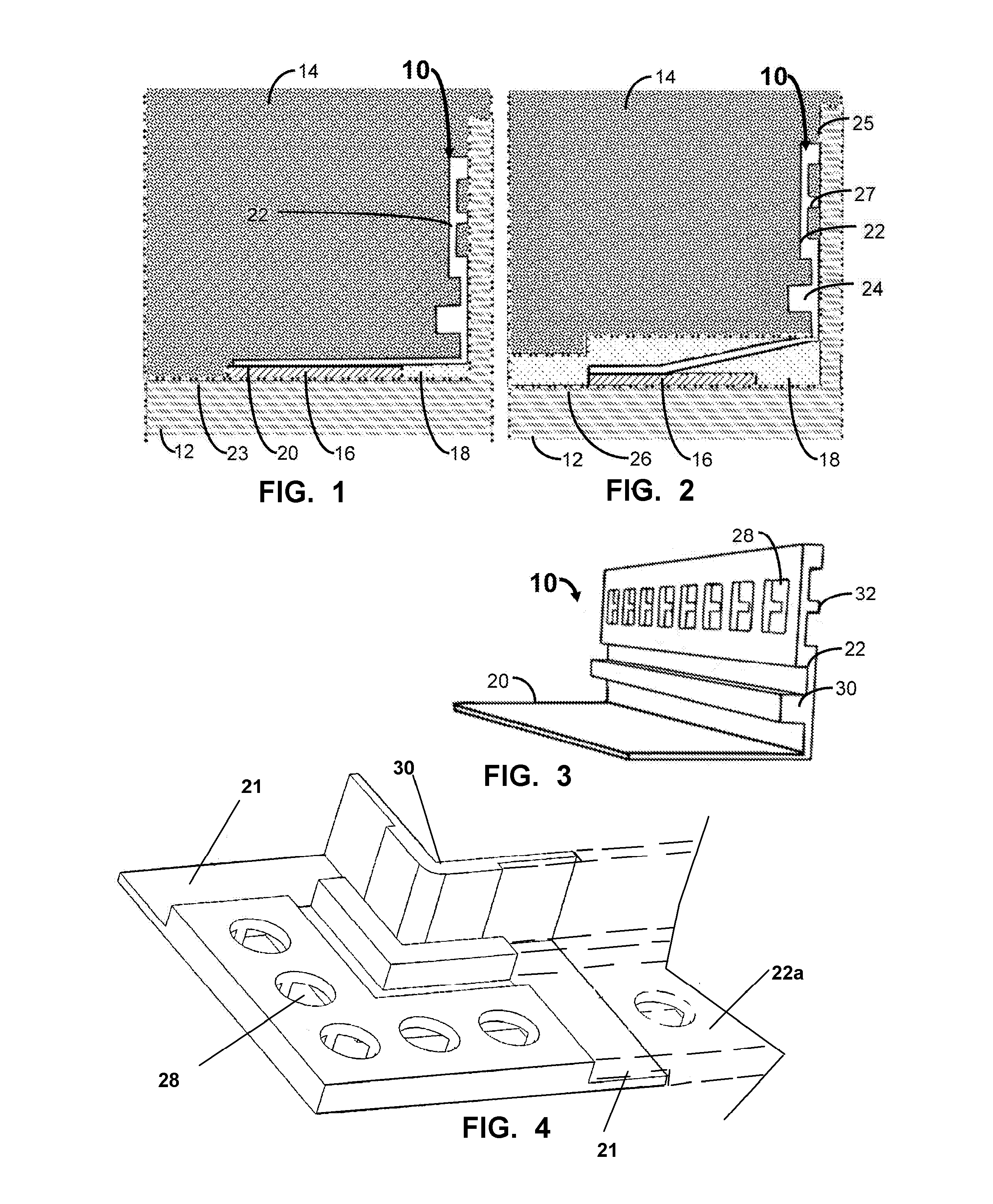

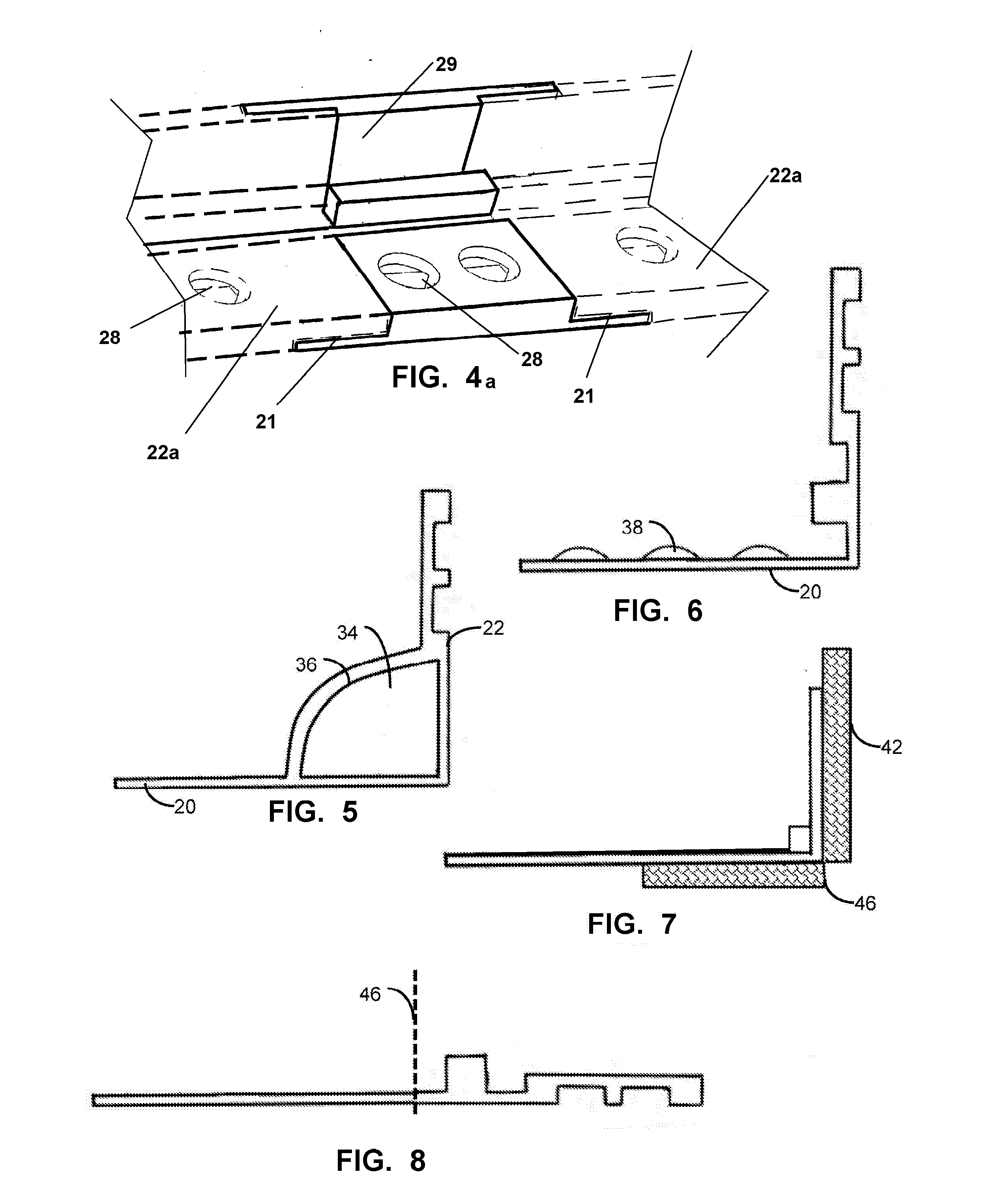

ActiveUS7422030B2Reliable and effective for ventingEfficiently move and directsCheck valvesEqualizing valvesFluid systemVALVE PORT

A one directional flow valve assembly for a fluid system. The valve assembly is comprised of a valve body having an internal valve chamber in communication with the ambient environment and a valve seat arrangement. The assembly further has a cap structure with means to position and align a sealing member with respect to the valve seat. A flexible elastomeric sealing diaphragm may be utilized and which is under tension when the sealing diaphragm is in a sealing configuration. The sealing member has a peripheral deflection shield to direct ambient fluid through the valve body. A carrier plate structure may be provided to position the sealing member and deflection shield with respect to the valve seat arrangement to operate the valve assembly.

Owner:OATEY CO

Liquid level seal connector and underwater connection signal transmission and air guide method thereof

ActiveCN105305150AFlexible separationEasy to replaceCoupling device engaging/disengagingCouplings bases/casesTransmitterSignal lines

Owner:MICRO SENSOR

Rotary joint

The invention relates to a rotary joint and belongs to the technical field of heat power pipe network matching. The joint comprises an outer pipe, an inner pipe and a gland, wherein an inner convex ring is arranged inside the outer pipe, an outer convex ring is arranged outside the inner pipe, the inner convex ring and the outer convex ring are respectively provided with V-shaped grooves of which openings are opposite, and obliquely-arranged cylindrical rollers are mounted inside the V-shaped grooves; one end of the inner convex ring adopts an expanding section with an annular space, and a C-shaped elastic metal sealing ring is embedded into the annular space; a trapezoidal baffle ring with an inclined plane at one end is mounted at the other end of the inner convex ring, the inner end of the gland adopts an inclined plane which is opposite to the inclining direction of the trapezoidal baffle ring, and a graphite filling material sealing ring is mounted between the trapezoidal baffle ring and the gland. After the adoption of the invention, the C-shaped elastic metal sealing ring and the graphite filling material sealing ring form high-temperature resistant and high-voltage resistant double sealing, the arranged direction of a bearing and the trapezoidal cross section graphite filling material sealing ring form a reasonable force bearing system. Therefore, the rotary joint provided by the invention has remarkable advantages that reliable sealing under high-temperature and high-voltage conditions is kept while free rotation can be ensured.

Owner:AEROSUN CORP

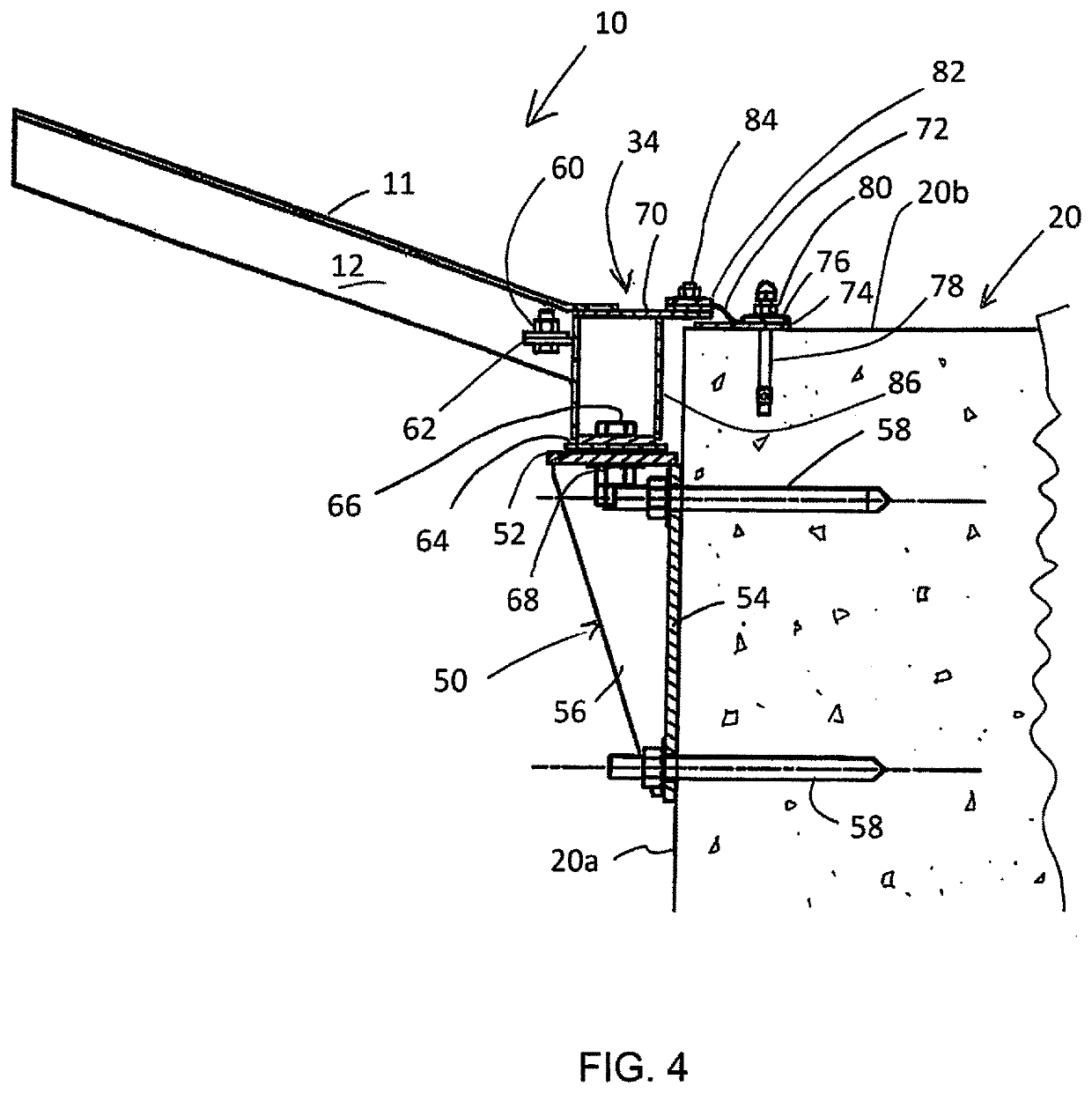

Membrane Interface for Building Apertures

InactiveUS20140202103A1Flexible sealKeep in touchCovering/liningsFloorsMoistureMembrane configuration

An expanding seal for preventing water and air intrusion in gaps formed between aperture-engaged components of a wall which are surrounded by stucco or the like is provided. The device is configured to prevent moisture ingress between formed gaps created as stucco surfaces expand and contract over time which can exacerbate gaps. A first side of the body of the device engages the fixture while the opposing side is adapted for an embedded engagement with cured stucco whereby intrusion into gaps is prevented by elastic expansion and contraction of the seal.

Owner:CAMPBELL VANCE

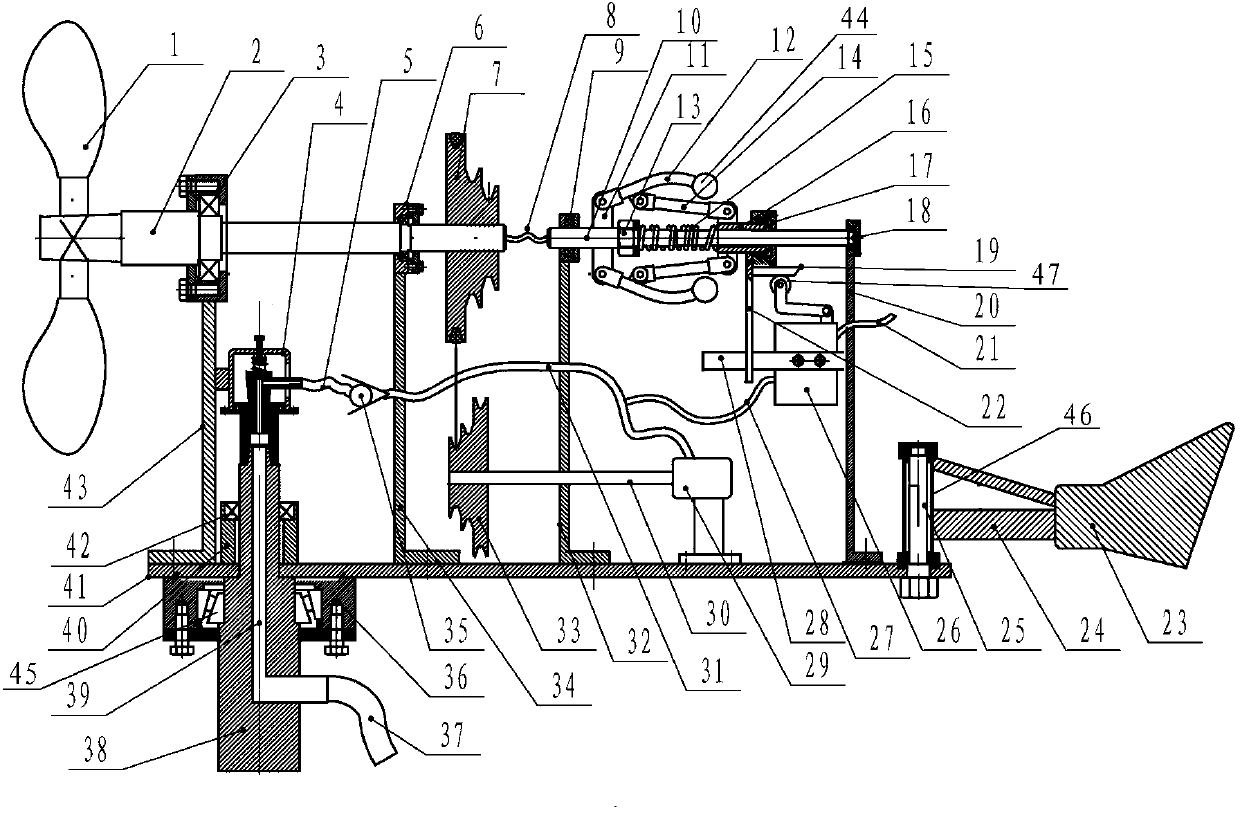

Wind power air compressor system

InactiveCN103343736AIncrease profitFlexible sealPiston pumpsPositive-displacement liquid enginesGas compressorAir compressor

The invention discloses a wind power air compressor system. The wind power air compressor system comprises a stand column with a gas transmission channel, a wind power mechanism, an air compressor sub-system and a load-free centrifugal start control mechanism, wherein the wind power mechanism comprises fan blades, a main shaft, a driving pulley, a rotating chassis and a tail wing; the air compressor sub-system comprises an air compressor, a driven pulley arranged on a power shaft of the air compressor, a normal close button valve and a rotating joint; the rotating joint comprises a static joint, a moving joint and a hold-down mechanism; the lower end of the moving joint is inserted into the static joint, and the contacting surface of the moving joint and the static joint is a cone surface; the hold-down mechanism comprises a shield, an annular shield base, an adjustable bolt, a pressure spring and an upper spring base, the moving joint is communicated with an air channel of the static joint, and the load-free centrifugal start control mechanism comprises a centrifugal shaft, a pair of driving centrifugal rods, a centrifugal ball, a pair of driven centrifugal rods, a shaft sleeve and a button valve control mechanism. The wind power air compressor system provided by the invention has the advantages that the load-free starting is adopted, the utilization rate of wind energy is high, and the rotation is flexible.

Owner:张家政

Double-gate-plate wedge gate valve

PendingCN113639061AFlexible moving processSatisfy cut-off requirementsOperating means/releasing devices for valvesSlide valveEngineeringControl valves

The invention discloses a double-gate-plate wedge gate valve. The double-gate-plate wedge gate valve comprises a valve body, a flow channel, a closing part, a driving part, a bypass assembly and a valve deck. The flow channel is formed in the valve body, the closing part is used for controlling opening and closing of the flow channel, the driving part is used for providing driving power for action of the closing part, the valve deck is arranged at the right end of the valve body, the bypass assembly is arranged outside the valve deck, connected with the valve deck and used for controlling an external gas source to input low-pressure inert gas into the valve deck, and the valve deck is further linked with the driving part to control closing of the flow channel in the valve body. The double-gate-plate wedge gate valve is provided with a double-gate-plate structure, and bidirectional forced sealing can be achieved; when the valve is opened and closed, only the friction force at the inclined surface of a wedge block needs to be overcome, and gate plates can flexibly move after the wedge block moves; and when the valve is closed, the external gas source is controlled through valve rod limiting to input the low-pressure inert gas to assist in sealing, and when the valve is opened, input of the external gas source is controlled through valve rod limiting to be cut off.

Owner:JIANGSU SHENGTAI VALVE CO LTD

Automatic ascending and descending tail sealing device

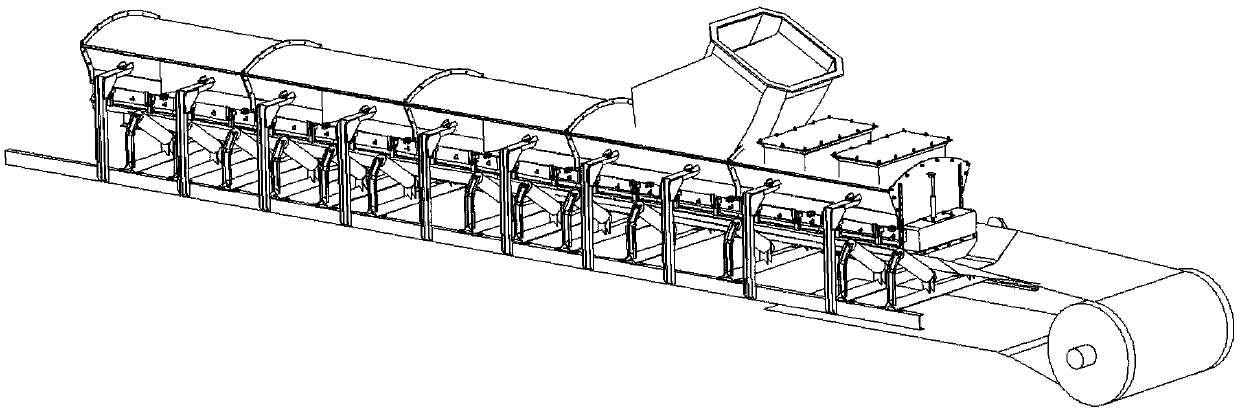

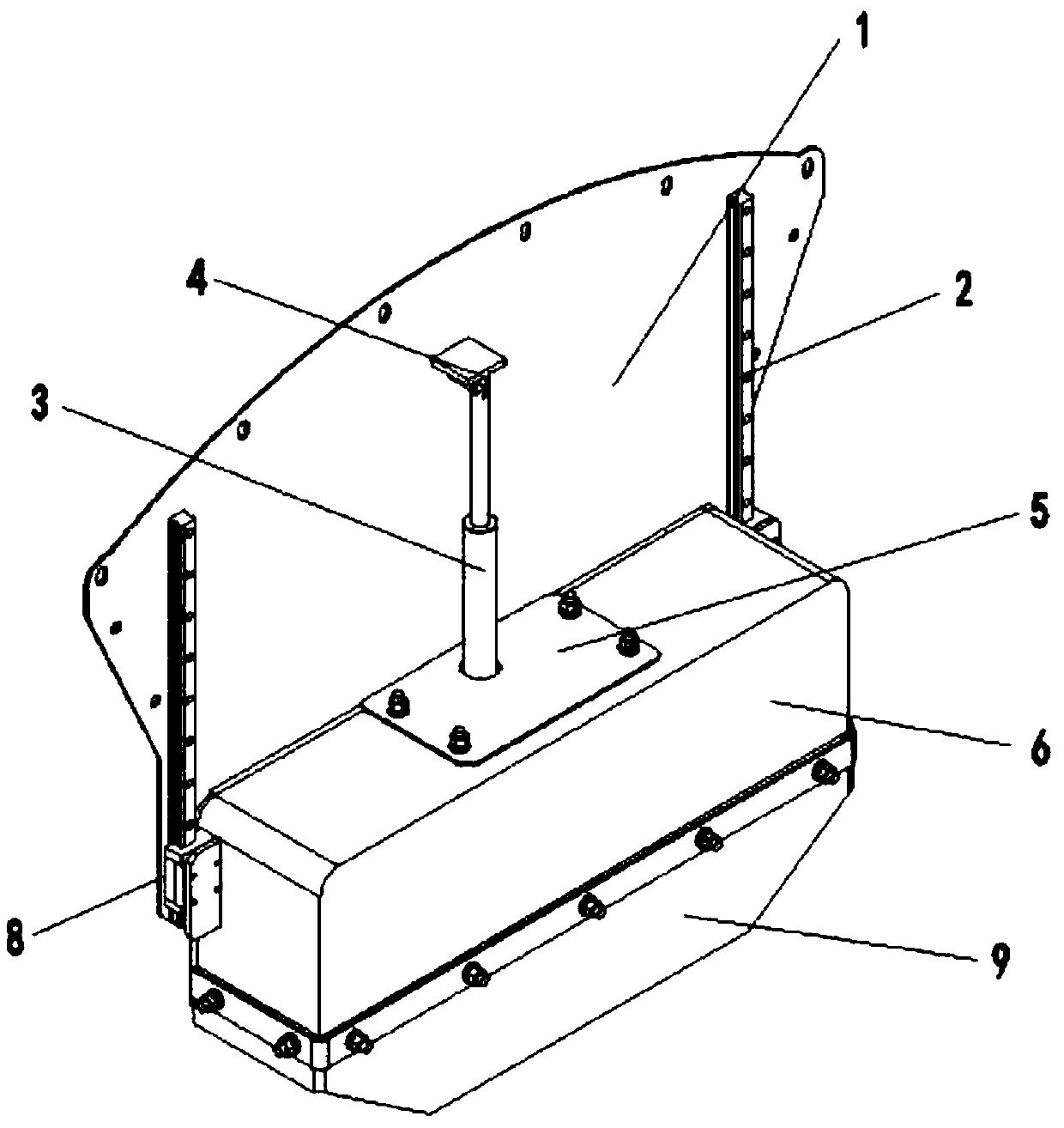

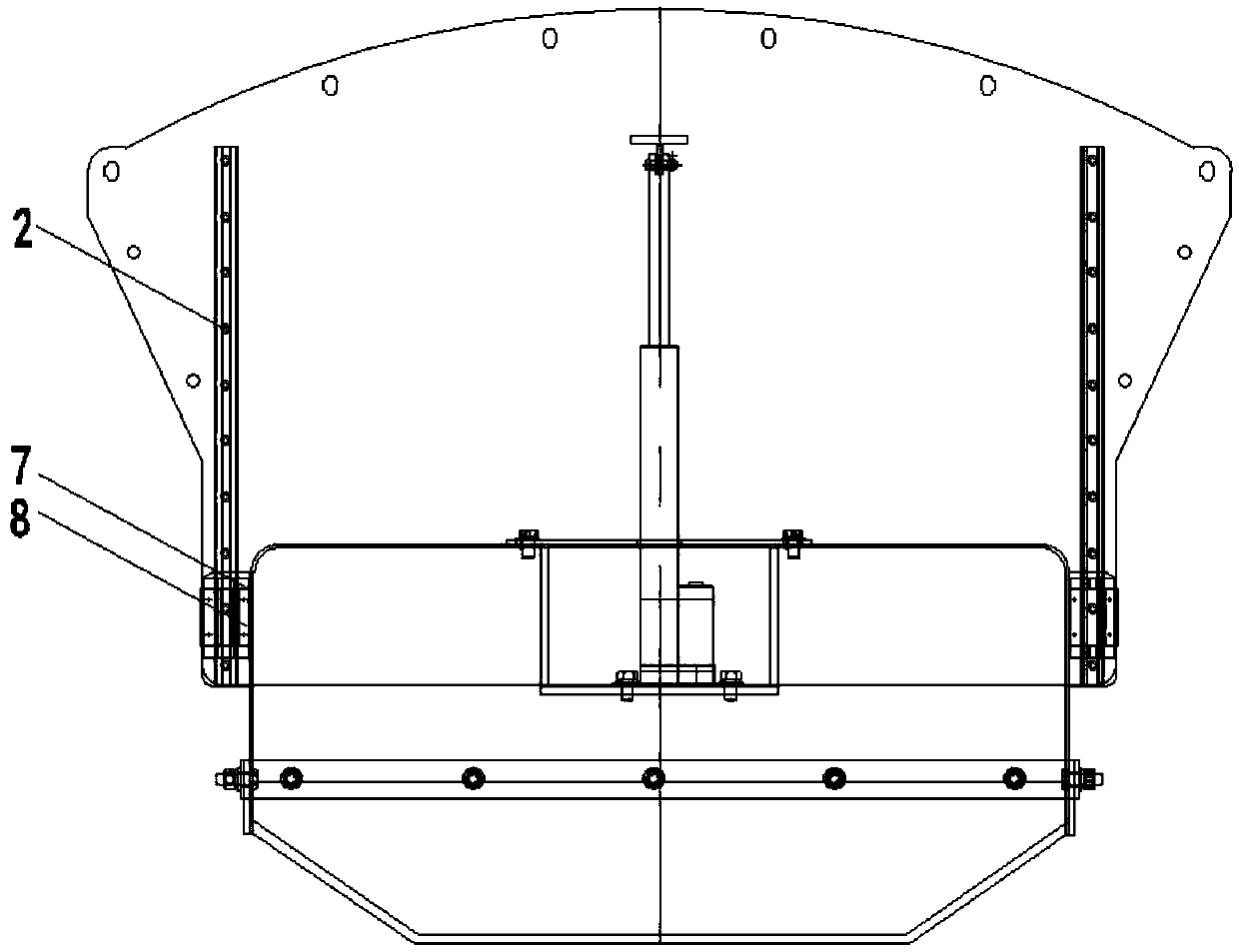

InactiveCN109573661ASave cleanup timeFlexible liftingLoading/unloadingConveyor partsBlocked ConnectionMechanical engineering

The invention discloses an automatic ascending and descending tail sealing device comprising a connection board. The back face of the connection board is connected with the tail of a guide groove; thefront face of the connection board is provided with two parallel moving slide rails; a push rod bracket is arranged on the connection board and connected with an electric push rod; a sealing box is connected with the lower portion of the electric push rod; slide block connection bases are arranged on two sides of the sealing box; slide blocks are arranged inside the slide block connection bases and can vertically move along corresponding moving slide rails; and the bottom of the sealing box is sequentially connected with a front sealing board, a middle sealing board and a rear sealing board from front to back. The bottom of the sealing box is of a multi-layer sealing design to seal the guide groove, the material pouring and powder spraying phenomena on a working site are avoided, at the same time, when a bidirectional belt reversely works or scattered materials at the tail of the belt need to be cleaned away, the electric push rod pushes the sealing box to vertically move on the connection board, and the sealing box can ascend or descend.

Owner:湖北展高机械装备有限公司

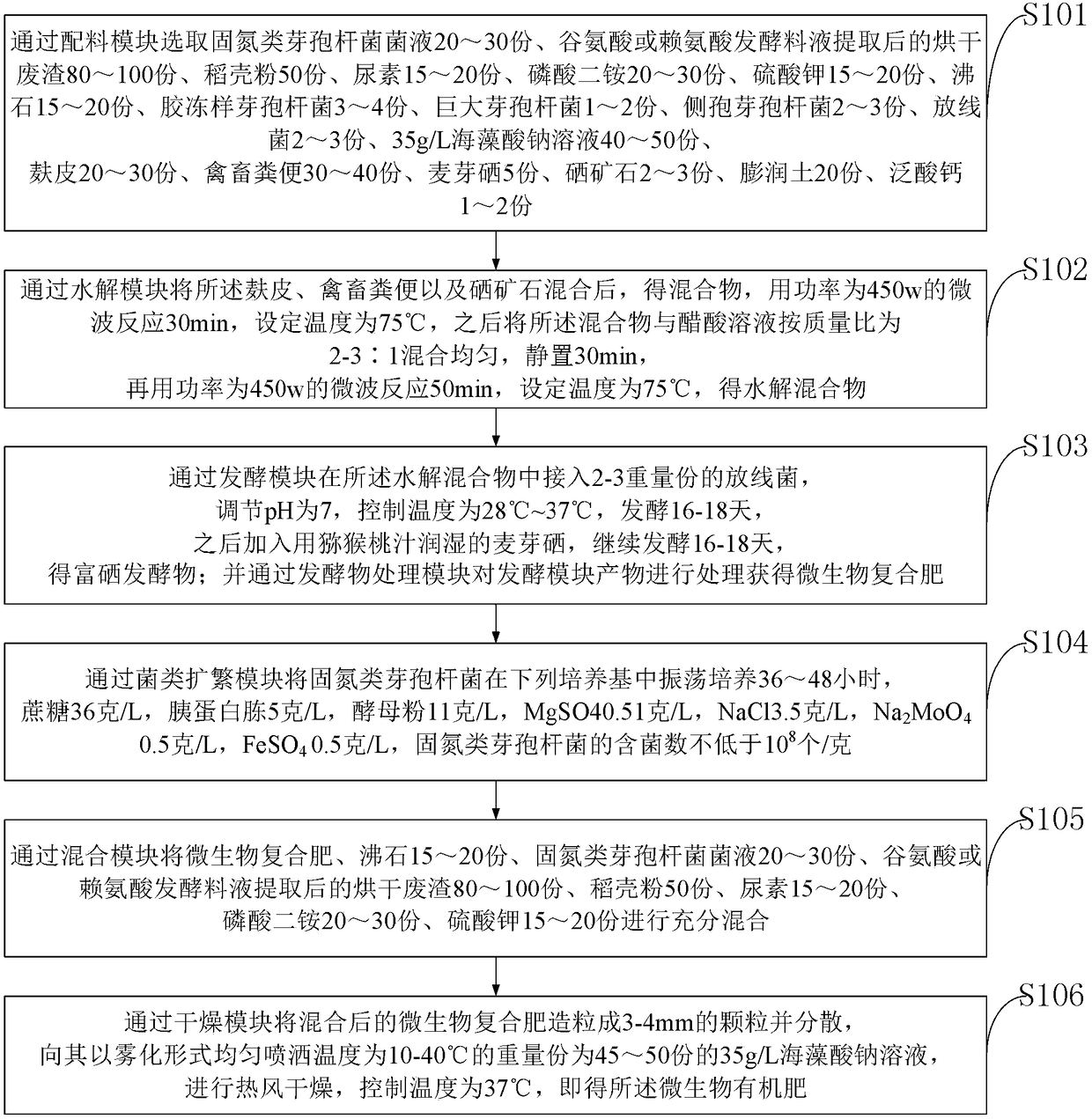

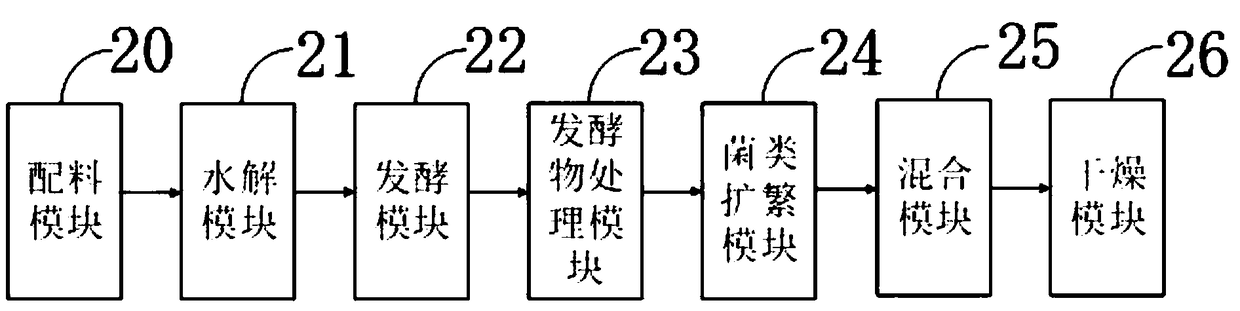

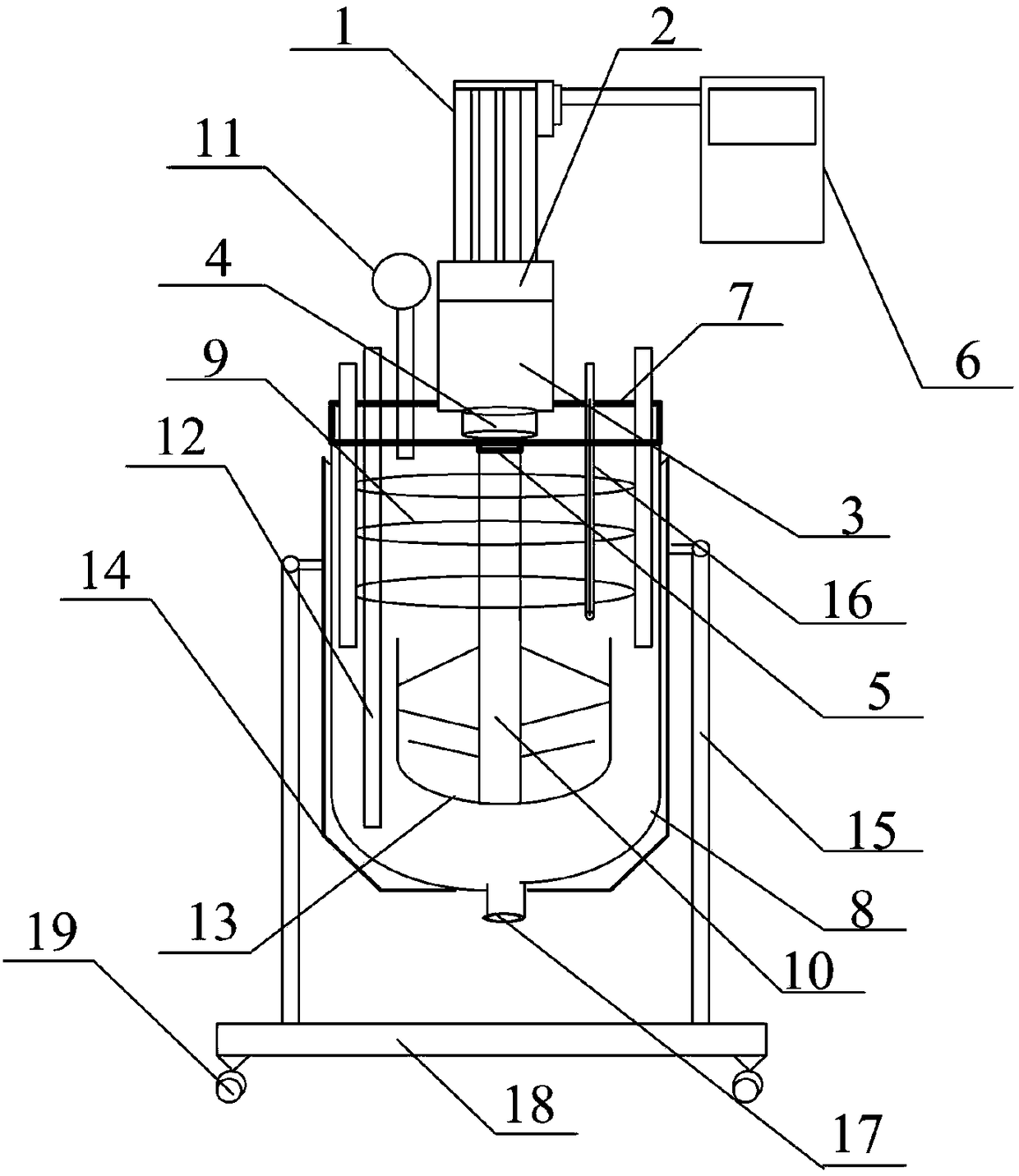

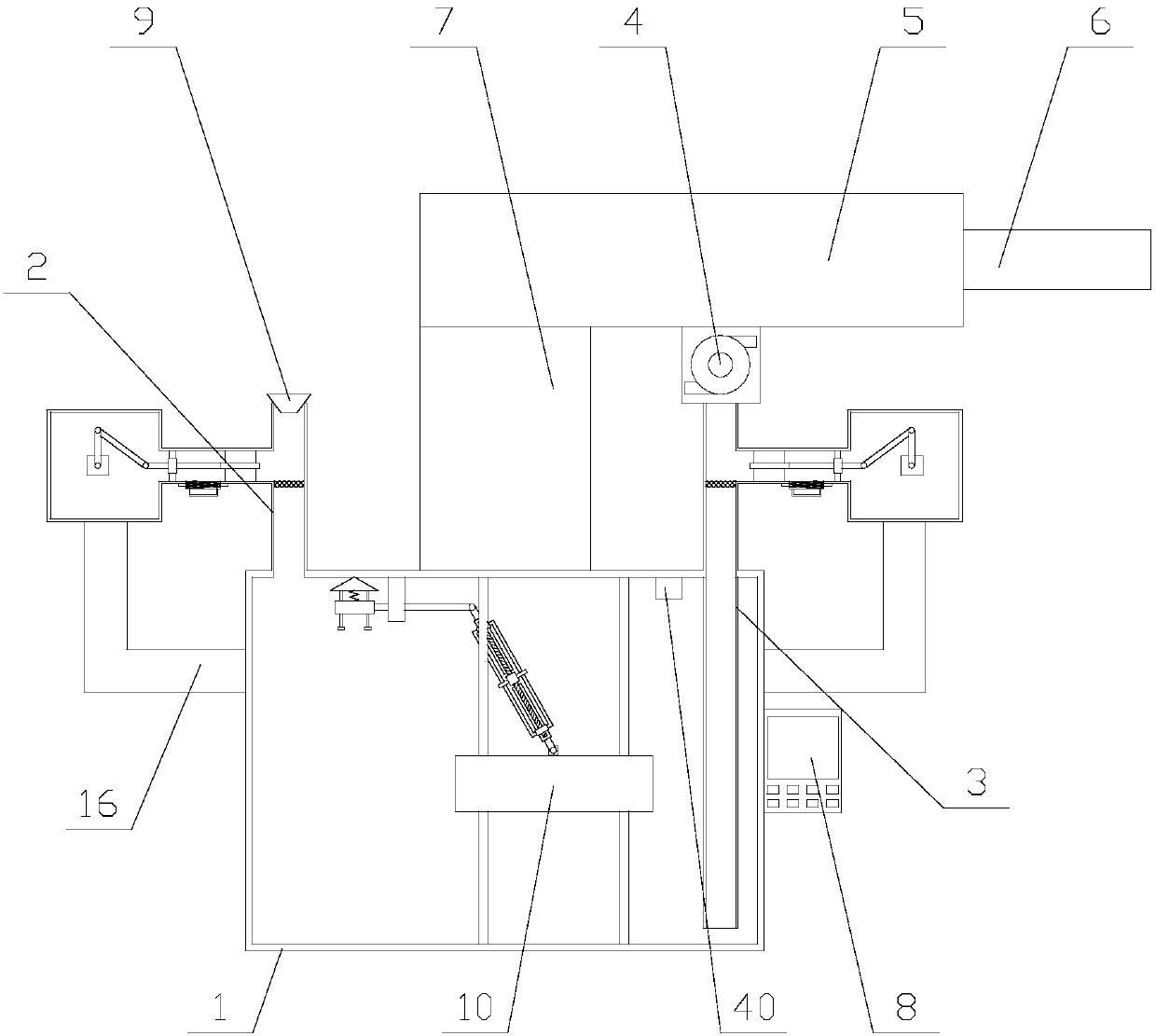

Preparation method of compound microbial organic fertilizer of trace elements and actinomycetes in slow release

InactiveCN108586054APromote growthImprove disease resistanceCalcareous fertilisersAlkali orthophosphate fertiliserInsect pestBran

The invention belongs to the technical field of fertilizer preparation, and discloses a preparation method of a compound microbial organic fertilizer of trace elements and actinomycetes in slow release, which comprises the following steps: selecting an ingredient through a batching module, mixing a bran, livestock dung and a selenium through a hydrolysis module, hydrolyzing to obtain a hydrolysismixture; inoculating actinomycetes in the hydrolysis mixture through a fermentation module, adjusting the pH, and fermenting. The preparation method of a compound microbial organic fertilizer of traceelements and actinomycetes in slow release uses sodium alginate as a coating agent to prepare a slow-release biological organic fertilizer; improves the disease resistance of the crops and the characteristics of promoting the growth of the plants (the disease resistance of a certain gram-positive bacteria can be targeted) by using actinomycetes to release the containing sugar-peptide ingredient,sugar-the lipid component ; meanwhile, provides the nutrition needed for plant growth, promotes the growth of the plants, improves the utilization rate of the chemical fertilizer, reduces the occurrence of diseases and insect pests, enhances the stress resistance of the crops, improves the quality and the yield of the crops, has an important effect, can be popularized and used in the agriculturalproduction.

Owner:QILU UNIV OF TECH

Anti-blocking intelligent hydraulic hoist with quantitative control function

ActiveCN110159601AAvoid cloggingSmooth circulationBarrages/weirsServomotor componentsHydraulic cylinderFuel tank

The invention relates to an anti-blocking intelligent hydraulic hoist with a quantitative control function. The anti-blockage intelligent hydraulic hoist comprises an oil tank, an oil injection pipe,an oil pumping pipe, a hydraulic pump, a hydraulic cylinder, a piston, a supporting block and a controller; the side, away from the supporting block, of the oil injection pipe is provided with a cleaning mechanism, and the side, away from the supporting block, of the oil pumping pipe is provided with a cleaning mechanism; a quantitative mechanism is arranged in the oil tank, wherein the quantitative mechanism comprises a floating block, a connecting assembly, a sliding rod, a balancing block, a sealing assembly and four fixing rods; and each cleaning mechanism comprises a cleaning pipe, a driving chamber, a supporting frame and a sealing assembly, and each cleaning pipe is provided with a frame and a sponge block. According to the anti-blocking intelligent hydraulic hoist with the quantitative control function, dust impurities adsorbed on a filter screen can be adsorbed in time through the cleaning mechanisms, so that net holes of the filter screen are prevented from being blocked, andthe smooth circulation of hydraulic oil is guaranteed; and moreover, in the oil tank, the quantitative mechanism can automatically realize sealing of the oil injection pipe according to the oil level, the quantitative hydraulic oil is conveniently added into the oil tank, and the practicability of equipment is improved.

Owner:扬州市慧宇科技有限公司

Atomospheric pressure glow discharge plasma reactor possessing rotary relix electrode

InactiveCN100368073CFlexible sealPrecise ratioHydrocarbon by hydrocarbon condensationEnergy based chemical/physical/physico-chemical processesAtmospheric airEngineering

Owner:DALIAN UNIV OF TECH

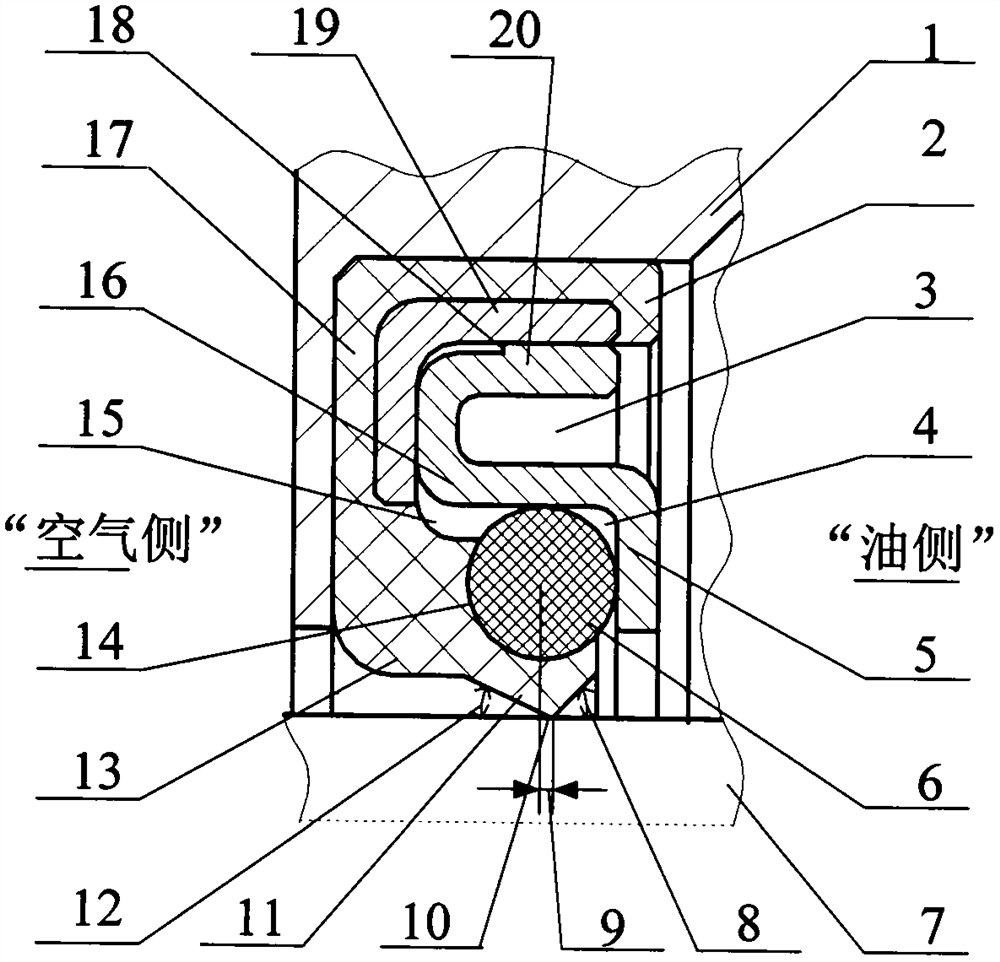

Novel rotating shaft sealing device

PendingCN114738466AImprove stabilityIncrease contact stressEngine sealsGearing detailsPhysicsRotational axis

The invention provides a novel rotating shaft sealing device which comprises a lip-shaped seal, an elastic force compensation O-shaped ring and an adaptive ring which are sleeved in a bearing cover cavity, the lip-shaped seal is composed of a lip part, a supporting part, an outer gluing part and an L-shaped exposed metal framework, a C-shaped cavity is formed, a lip tip is arranged at the contact position of the lip part and a rotating shaft, and the elastic force compensation O-shaped ring is arranged on the lip tip. A semi-circular groove is formed in the outer upper edge, an air side lip corner and an oil side lip corner are arranged on the left side and the right side of the lip tip respectively, the elastic compensation O-shaped ring is made of rubber materials and sleeved with the semi-circular groove, the adaptive ring is composed of an upper supporting section and a lower pressurizing section, the profile of the section of the adaptive ring is in an S shape, and a U-shaped deformation cavity and a semi-closed pressurizing cavity are formed. A tiny protrusion is arranged on the upper edge of the outer portion of the upper supporting section and pressed into a C-shaped cavity of the lip-shaped seal, the lower pressurizing section presses and seals the elastic compensation O-shaped ring, and the elastic compensation O-shaped ring is wide in application range, good in sealing flexibility, high in dynamic eccentricity compensation capacity, small in friction torque, good in sealing performance and long in service life.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Steel stranded rubber support and production method thereof

ActiveCN102425106BEasy to installPrevent voltage biasBridge structural detailsElastomerStructural engineering

The invention belongs to the technical field of bridge supports, and discloses a steel stranded rubber support and a production method thereof. The steel stranded rubber support is mainly technically characterized by comprising a convex spherical crown steel stranded support with a convex spherical surface and a concave spherical crown steel stranded support with a concave spherical surface, wherein the convex spherical crown steel stranded support and the concave spherical crown steel stranded support are coated or partly coated by an elastomer. The steel stranded rubber support provided by the invention is large in corner so as to be capable of self-adapting to a corner of a girder body and to effectively prevent biasing of plate type rubber supports. And the convex spherical crown steel stranded support and the concave spherical crown steel stranded support are coated or partly coated by the elastomer, therefore, the stress is not further applied to the peripheral rubber of the support and other elastomer protection layers, and good sealing performance and long service life are achieved. The steel stranded rubber support has the advantages of plate type supports and global supports, also has the advantages of convenience for installation and low cost, and is free of maintenance.

Owner:HEBEI BAOLI ENG EQUIP GRP CO LTD

Liquid-level sealed connector and method for connecting signal transmission and gas conduction under water

ActiveCN105305150BFlexible separationEasy to replaceCoupling device engaging/disengagingCouplings bases/casesUnderwaterTransducer

The invention relates to a liquid level sealing connector and its method for connecting and transmitting signals and guiding gas under water, comprising a cable, one end of the cable is sheathed with a shell cap, and the front end of the shell cap can be socketed in the sensor part of the transmitter In the sensor housing, a first sealing device is provided at the joint between the housing cap and the sensor housing, and a second sealing device for sealing the cable and the housing cap is provided at the tail end of the housing cap; the plug of the connector is installed inside the housing cap, and the plug It is connected with the cable; the socket of the connector is installed in the sensor housing and connected with the signal line of the transmitter to form an integrated connector structure. In the present invention, the shell cap is socketed in the sensor shell to realize the flexible separation of the sensor part of the transmitter from the cable and the power supply, which is convenient for replacement and maintenance; the shell cap and the sensor shell are sealed and formed by the first sealing device and the second sealing device A cavity, cables, plugs and sockets are in the cavity, effectively isolated from the external medium, with good sealing effect, high protection level and good reliability.

Owner:MICRO SENSOR

A sealing mechanism against gas exchange

ActiveCN104728448BAvoid swappingAvoid enteringEngine sealsSludge treatment by pyrolysisGas exchangeMechanical engineering

The invention relates to a sealing mechanism preventing gas exchange. The sealing mechanism comprises a stress block (3), a pressing block (4) and a compressing mechanism (5), wherein the stress block (3) is connected with a fixed part (1) and is in clearance fit with a rotating part (2); the pressing block (4) is in clearance fit with the rotating part (2) in a rotating mode; the compressing mechanism (5) is fixedly connected with the rotating part (2); the pressing block (4) presses the stress block (3) through the compressing mechanism; the stress block (3) is provided with a first sealing strip (3c); a second sealing strip (4e) is placed in a cavity (4d) of the pressing block (4); a first gap (2a) formed between the pressing block (4) and the outer wall surface of the rotating part (4) is sealed through the second sealing strip (4e); a threaded rod (7a) of a compressing screw (7) of the compressing mechanism (5) applies pressure to a force applying surface (4a2) of the pressing block (4), and the pressing block (4) compresses the first sealing strip (3c) of the stress block (3) through a first pressing surface (4a2) of a compressing surface (4a1) so that a second gap (8) formed between the pressing block (4) and the stress block (3) can be sealed. The sealing function is achieved through the simple mechanical sealing mechanism, gas exchange through the gap formed between the fixed part and the rotating part is prevented, in this way, external gas is prevented from entering the rotating part through the gap, and meanwhile gas inside the rotating part is prevented from leaking outwards through the gap.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

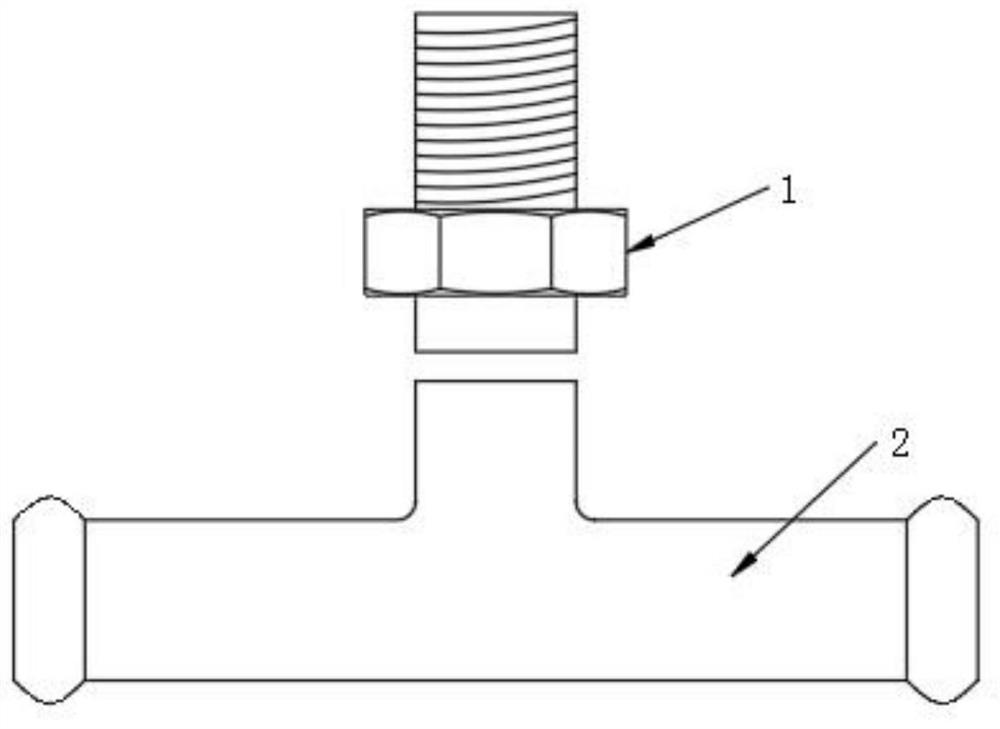

Welding process for stainless steel pipe fitting

The invention discloses a welding process for a stainless steel pipe fitting. The welding process comprises the following steps of S1, manufacturing a threaded part; S2, extruding a molded part, specifically, processing a thin-wall pipe by virtue of an extrusion molding machine to form the molded part with one closed end; S3, preheating, specifically, heating the threaded part and the molded partto 500 DEG C through a heater; S4, performing vacuum sealing, specifically, clamping the threaded part at a rotating end of a welding machine, clamping the molded part at a moving end of the welding machine, forming a sealed space by means of a housing, and vacummizing the sealed space; S5, performing friction welding, specifically, driving the threaded part by a motor to rotate at a high speed, meanwhile, enabling the molded part to gradually get close to the threaded part under the action of axial force of an oil cylinder piston, and after the threaded part makes contact with the molded partand is pressed tightly, maintaining the state for 6s; and S6, upsetting, specifically, performing braking, enabling the axial force to rapidly increase to the set upsetting pressure of 3.0-4.0MPa / mm2for upsetting, and the upsetting pressure maintaining time is 1-5 seconds. By means of cooperation of friction welding, preheating and vacuum welding, high-quality welding of the stainless steel pipefitting is achieved.

Owner:无锡金羊管件有限公司

Rod bundle channel flow pressure measurement experimental device

ActiveCN106683722BEasy to moveSmooth rotationNuclear energy generationNuclear monitoringRotary stageWater storage tank

The invention provides a rod bundle channel flow pressure measuring test device, which comprises a water storage tank, a pressure measuring body, and a centrifugal pump, a regulating valve and a thermometer sequentially connected with the water storage tank through a pipeline, wherein the pressure measuring body comprises a rod bundle channel barrel, a rod bundle channel formed by rod bundles arranged in the rod bundle channel barrel; the upper ends of the rod bundles are connected with a high-accuracy rotating disk arranged on a rotating table support through a coupler; two body pressure ports formed up and down are formed in the rod bundle channel barrel; a pressure guiding port is formed in each rod bundle of the rod bundle channel; a sealing rubber plug is arranged at the lower end of each rod bundle; a fast adapter is arranged at the upper end of each rod bundle; pressure difference transmitters are respectively arranged between each pressure guiding port and each fast adapter as well as between the two body pressure ports. The rod bundle channel flow pressure measuring test device provided by the invention can simulate single-phase flow in a reactor rod bundle channel so as to research a resistance characteristic of the rod bundle channel, and is simple in structure, low in cost, accurate and convenient to acquire data, and wide in research working condition range.

Owner:HARBIN ENG UNIV

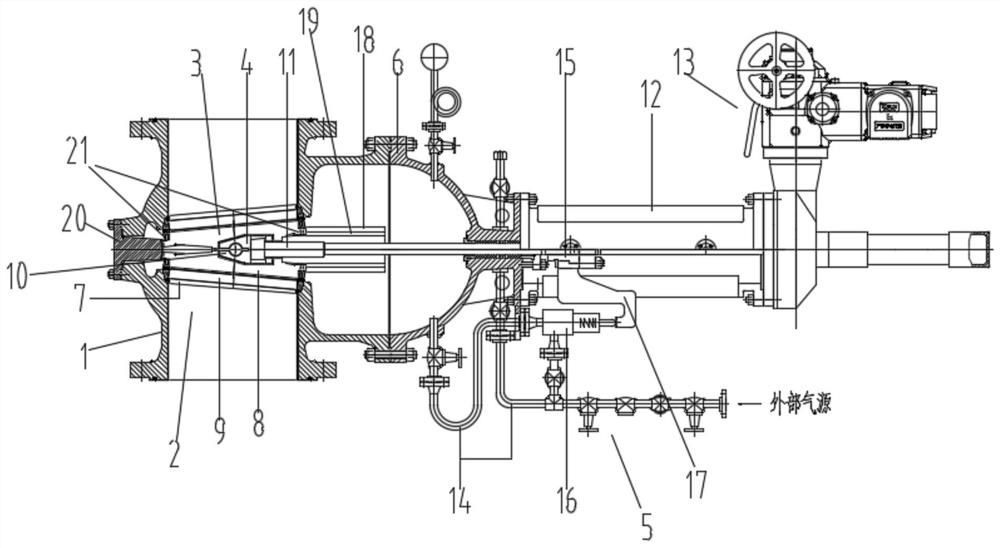

Fluoroplastic lining centrifugal pump

InactiveCN108869309APrevent liquid leakageProtection from corrosionSpecific fluid pumpsPump componentsCentrifugal pumpEngineering

The invention discloses a fluoroplastic lining centrifugal pump which comprises a pump body. A feeding opening is formed in one side of the pump body. A discharging opening is formed in one side, awayfrom the feeding opening, of the pump body. A feeding pipe is connected between the pump body and the feeding opening. A discharging pipe is connected between the pump body and the discharging opening. A lining is arranged in the pump body. An impeller is arranged in the lining. According to the fluoroplastic lining centrifugal pump, by arranging an anti-corrosion clamping ring, in the using process, the feeding pipe is connected with the feeding opening, then the anti-corrosion clamping ring is aligned to the connecting portion of the feeding pipe and the feeding opening, a moving ring is moved to enable an anti-corrosion layer to completely cover the connecting portion, finally, a butterfly nut on the outer side of a screw is screwed down, the anti-corrosion clamping ring is fixed, after the anti-corrosion clamping ring is used for a period of time, the butterfly nut can be loosened, a new anti-corrosion clamping ring is replaced, the device can seal a gap in the connecting portionof the feeding pipe and the feeding opening flexibly, the situation that the centrifugal pump works for a long time, and as a result, high-corrosion liquid in the pump body leaks can be prevented, andthe pump body is protected against corrosion.

Owner:合肥信仁液压机械有限公司

Diaphragm type pilot control solenoid valve

InactiveCN106015706AFlexible sealSeal B makes movement flexibleOperating means/releasing devices for valvesSolenoid valveEngineering

The invention relates to a diaphragm type pilot control solenoid valve. The diaphragm type pilot control solenoid valve comprises a valve seat; a valve cover is arranged at the upper part of the valve seat; pilot valve core iron is arranged at the intermediate position of the upper part of the valve cover; a pilot valve sealing piece is arranged at the bottom position of the pilot valve core iron; a conducting piece is arranged at the intermediate position of the valve cover; a mandrel sleeve is arranged on the outer side of the conducting piece; a movement limiting piece is arranged on the outer side of the mandrel sleeve; a sealing piece A is arranged at the lower part of the movement limiting piece; a sealing piece B is arranged between the lower part of the movement limiting piece and the conducting piece; a return spring is arranged between the outer side of the conducting piece and the movement limiting piece; a through hole is formed in the valve cover; a pilot valve cavity is formed in the upper part of the valve cover. A plurality of bulges are formed at the upper part of the movement limiting piece. A valve body inlet and a valve body outlet are respectively formed in the left side and the right side of the valve seat. According to the diaphragm type pilot control solenoid valve, the valve body is compact and the flow resistance of a pilot valve flow path can also be reduced, so that the valve body can obtain a greater allowable maximum operating pressure difference.

Owner:浙江盈亿机械股份有限公司

Recycling-friendly packaging laminate with improved thermal stability during sealing

InactiveCN110856442AImprove thermal stabilityWithout compromising recyclabilitySynthetic resin layered productsBagsPolymer scienceTotal thickness

The invention relates to a recycling-friendly packaging laminate having an exterior sealing layer (2) with a polyethylene content of at least 80 vol.%, a substrate layer (4) with a polyethylene content of at least 60 vol.% and a thermal stability layer (6), wherein the thermal stability layer (3) is arranged on the outside, opposite the sealing layer (2) and the substrate layer (4) is arranged between the sealing layer (2) and the thermal stability layer (3), wherein the thermal stability layer (3) is made of ethylene vinyl alcohol copolymer and the thickness of the thermal stability layer (3)amounts to up to 10% of the total thickness of the packaging laminate (1), but at most 10 [mu]m.

Owner:CONSTANTIA HUECK FOLIEN

An anti-clogging intelligent hydraulic hoist with quantitative control function

ActiveCN110159601BAvoid cloggingSmooth circulationBarrages/weirsServomotor componentsHydraulic cylinderHydraulic pump

The invention relates to an anti-blocking intelligent hydraulic hoist with a quantitative control function. The anti-blockage intelligent hydraulic hoist comprises an oil tank, an oil injection pipe,an oil pumping pipe, a hydraulic pump, a hydraulic cylinder, a piston, a supporting block and a controller; the side, away from the supporting block, of the oil injection pipe is provided with a cleaning mechanism, and the side, away from the supporting block, of the oil pumping pipe is provided with a cleaning mechanism; a quantitative mechanism is arranged in the oil tank, wherein the quantitative mechanism comprises a floating block, a connecting assembly, a sliding rod, a balancing block, a sealing assembly and four fixing rods; and each cleaning mechanism comprises a cleaning pipe, a driving chamber, a supporting frame and a sealing assembly, and each cleaning pipe is provided with a frame and a sponge block. According to the anti-blocking intelligent hydraulic hoist with the quantitative control function, dust impurities adsorbed on a filter screen can be adsorbed in time through the cleaning mechanisms, so that net holes of the filter screen are prevented from being blocked, andthe smooth circulation of hydraulic oil is guaranteed; and moreover, in the oil tank, the quantitative mechanism can automatically realize sealing of the oil injection pipe according to the oil level, the quantitative hydraulic oil is conveniently added into the oil tank, and the practicability of equipment is improved.

Owner:扬州市慧宇科技有限公司

A special compensator for maintenance-free pipe gallery system

ActiveCN106838524BNo thrustLarge compensation distanceEngine sealsPipeline expansion-compensationOuter CannulaMechanical engineering

The invention provides a special compensator for a maintenance-free pipe rack system. The compensator is located on a compensation mechanism mounting frame at least in the length direction of a pipeline; the compensation mechanism mounting frame is mounted on the ground; two ends of the compensator are respectively connected with an upstream pipe body and a downstream pipe body. The compensator is characterized by comprising an inner movable sleeve, an outer sleeve and an end pipe; the end part of the inner movable sleeve is fixed at the lower middle part in the outer sleeve; the end part of the end pipe is fixedly fitted to the inner wall of the top end of the outer sleeve, thus forming a three-layer sleeve structure. The special compensator for the maintenance-free pipe rack system has the outstanding characteristics of no thrust, large compensation distance, low operation cost and the like, and can meet the urban heating requirement.

Owner:JIANGSU FENGHE MACHINERY MFG

A special independent sealing compensator for pipe gallery system

ActiveCN106704757BThe reinforcement method is simpleEasy to reinforcePipeline expansion-compensationOuter CannulaEngineering

The invention provides an independent seal compensator special for a corridor system. The compensator comprises an inner movable casing, an outer casing and an end pipe. The end of the inner movable casing is fixed to the lower middle portion in the outer casing, the end of the end pipe is fixed to the inner wall of the top end of the outer casing in a fit manner, and a three-layer casing structure is formed. The tail end of the part, extending into the outer casing, of the inner movable casing is provided with an anti-pull-off device. The anti-pull-off device is fixed around to form a reinforcing region. The anti-pull-off device comprises a first reinforcing mechanism, a second reinforcing mechanism and reinforcing pieces. Each of the first reinforcing mechanism and the second reinforcing mechanism is composed of an arc-shaped plate structure and a straight plate structure. Each arc-shaped plate structure and the corresponding straight plate structure are integrally formed. The first reinforcing mechanism and the second reinforcing mechanism are correspondingly fixed to the two sides of the tail end of the part, extending to the outer casing, of the inner movable casing. The joint of the first reinforcing mechanism and the second reinforcing mechanism is fixed through the reinforcing pieces.

Owner:JIANGSU FENGHE MACHINERY MFG

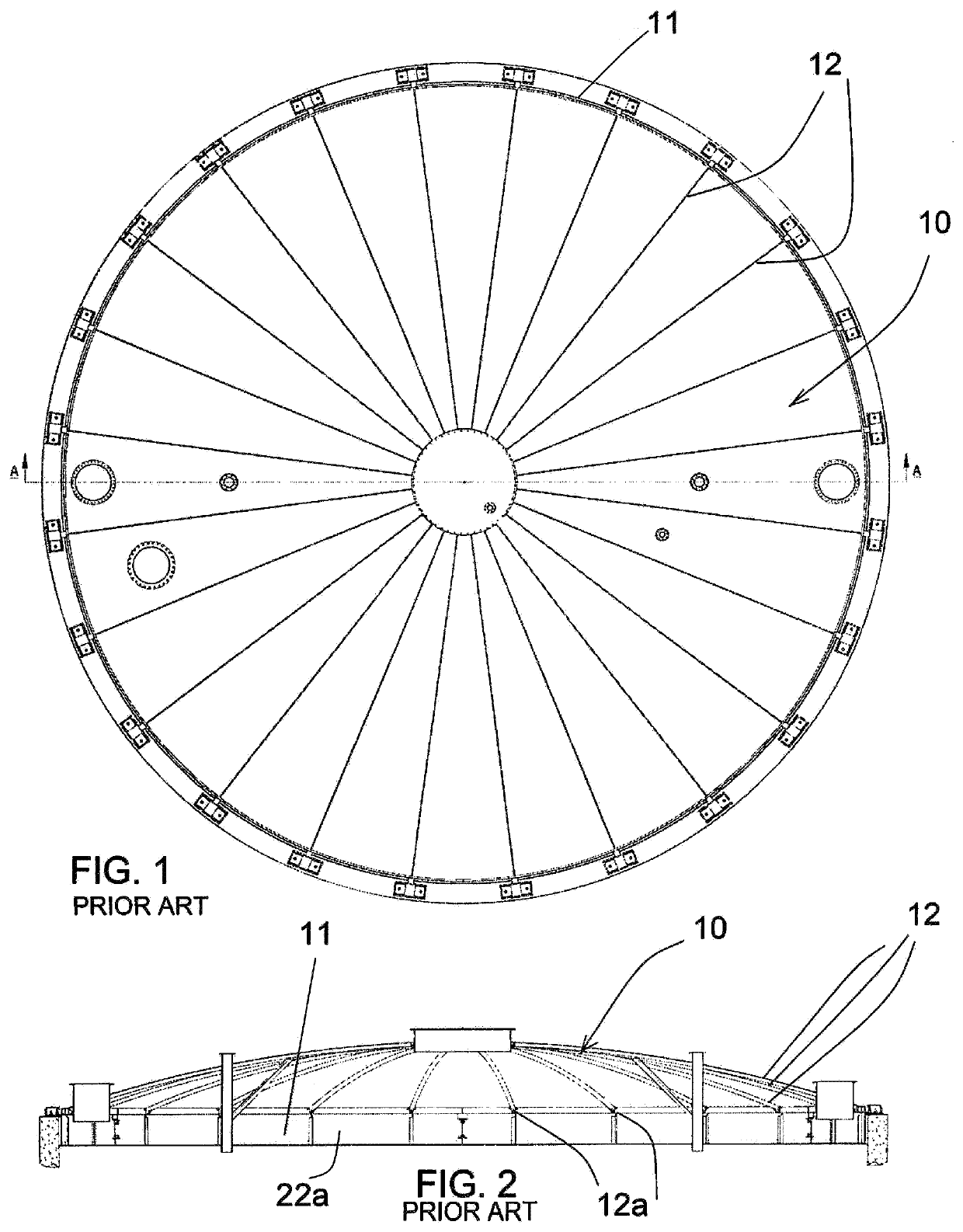

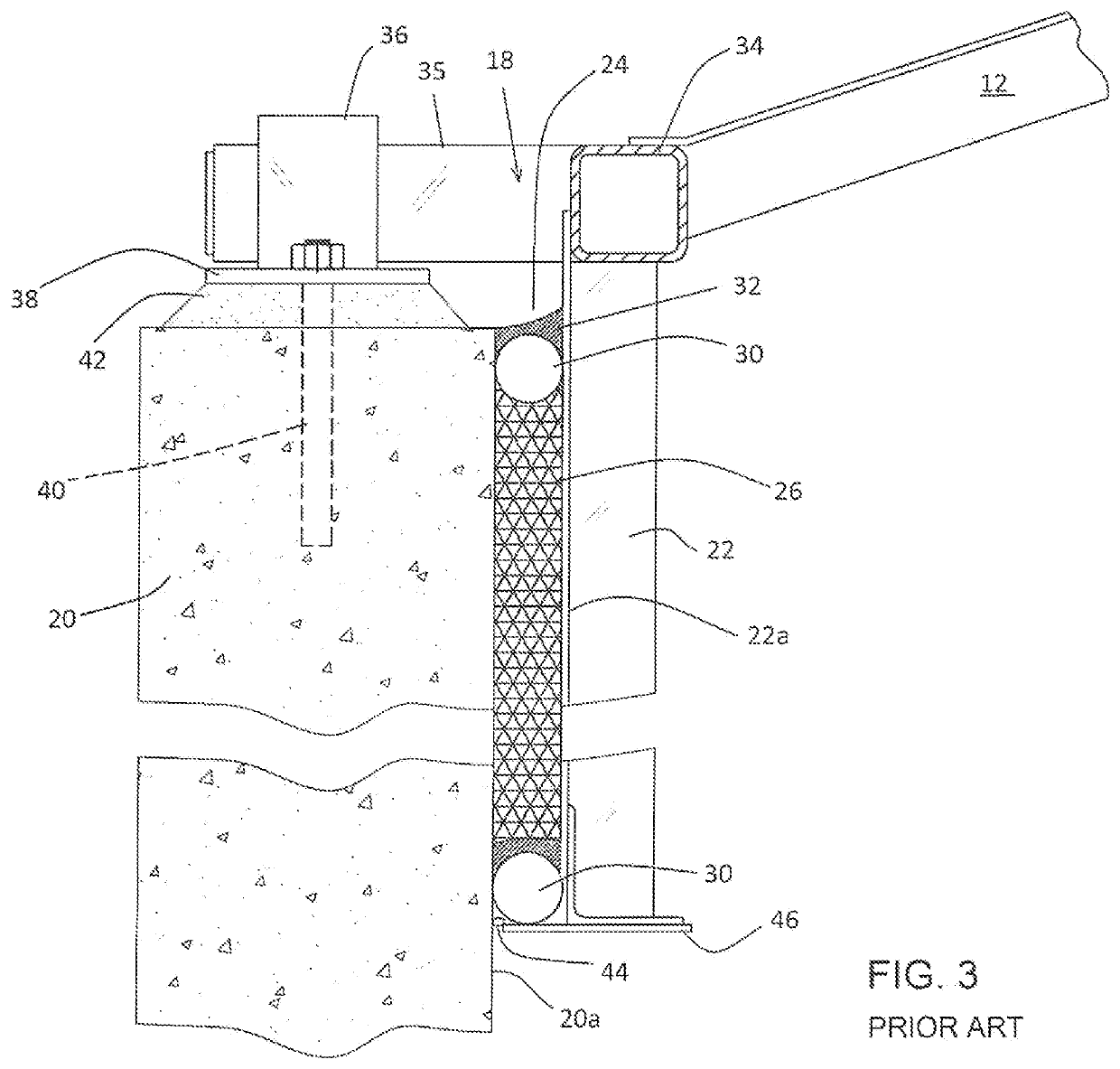

Seal for Cover on Wastewater Treatment Tank

PendingUS20220356007A1Simple and reliable sealing processFlexible sealLarge containersBulk storage containerThin membraneProcess engineering

A sealing system for a covered tank, particularly a fixed gas-sealing tank in a wastewater treatment system, includes a thrust ring positioned just inside the tank rim, secured to a series of radial beams for the cover. Preferably supported on corbels anchored to the interior tank wall, the thrust ring has an outwardly extending generally horizontal flange that overlies the edge of the tank rim. To this flange and to the top of the tank rim is secured a flexible membrane seal, around the periphery of the tank. The membrane seal is easily installed, reliable as a seal, and can be efficiently replaced when needed.

Owner:OVIVO INC

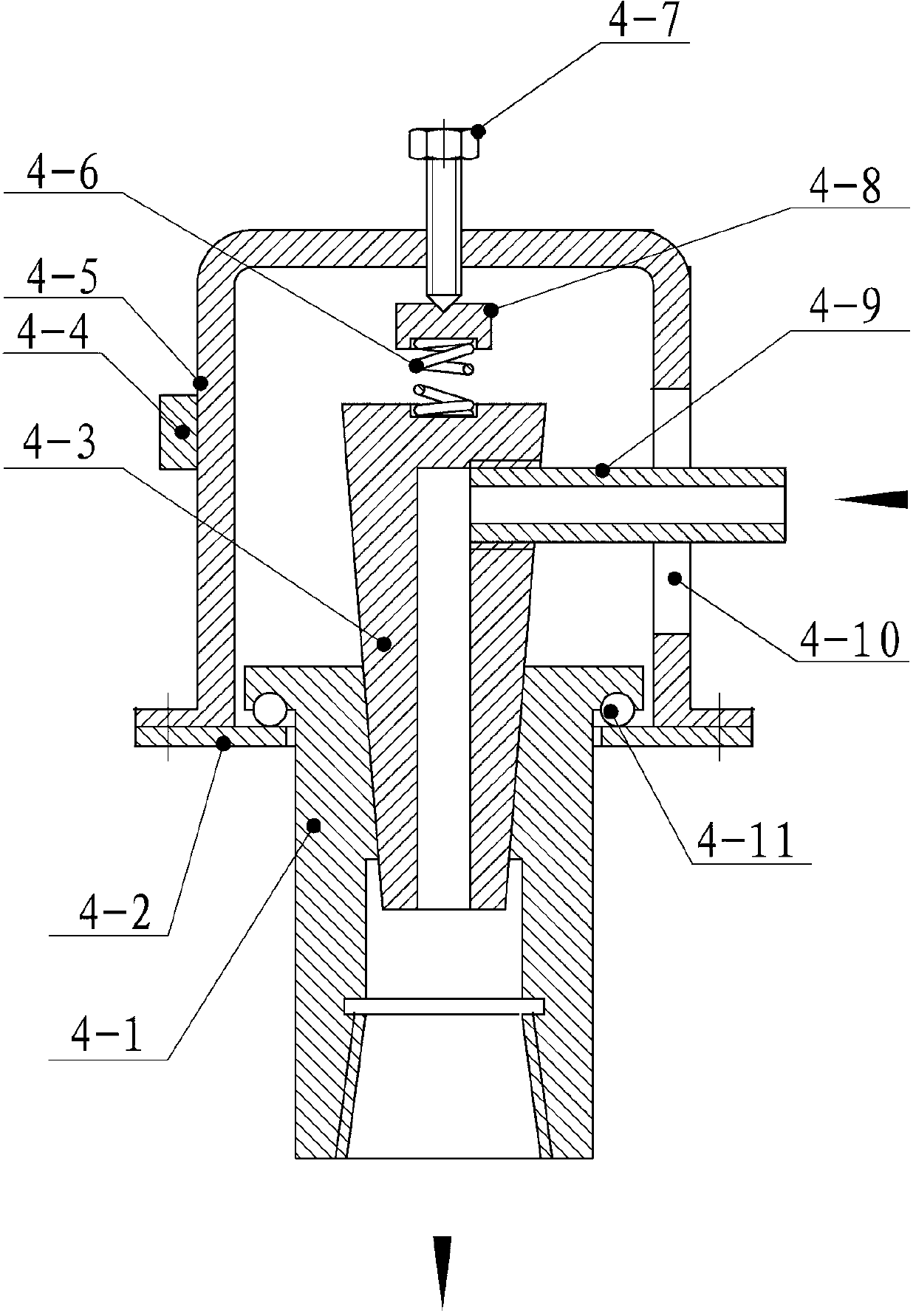

Gas path pressure release device and corresponding gas path pressure release device realizing large pressure reducing ratio

The invention relates to an air path relief device. A housing of the relief device is provided with a piston cavity. The two ends of the piston cavity are communicated and provided with a relief spring chamber and a top rod chamber in a same axis. The piston cavity is provided with a piston the inner end of which is in top pressure cooperation with the piston. The external end of the relief spring is in top pressure cooperation with a pressure regulating screw cap spirally arranged in an external port of the relief spring chamber. An inner axis of the top rod chamber is provided with the top rod the inner end of which is in top pressure cooperation with the piston. The top rod is provided with a top pressure spring driving the top rod to support and press the piston. The top rod chamber is communicated with an air inlet. The channel between the piston and the sealing structure is communicated and provided with an air distributing cabin. The sealing of the top rod chamber is realized by a spirally assembled sealing blank cover at the external port of the top rod chamber. A guiding hole of the top rod is arranged on an axis of the sealing blank cover. An external section of the top rod is inserted in the guiding hole. A ring groove is arranged at the circumferential surface of the external section of the top rod. A sealing ring in a sealing cooperation with the guiding hole is arranged in the ring groove. The external section of the top rod is also provided with a channel for communicating the air distributing cabin guiding hole. The channel includes a center blind pore arranged at the external section of the top rod and communicated with the guiding hole and an oblique hole arranged at the middle section of the top rod and for communicating the center blind hole and the air distributing cabin.

Owner:CAMA LUOYANG GAS SUPPLY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com