Gas path pressure release device and corresponding gas path pressure release device realizing large pressure reducing ratio

A decompression device and gas circuit technology, applied in the direction of valve device, fluid pressure control without auxiliary power, safety valve, etc., can solve the problems of cumbersome adjustment of decompression spring, large valve body diameter, unsuitable use, etc., to achieve Good pressure stabilizing effect, good sealing effect, reduced volume and mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

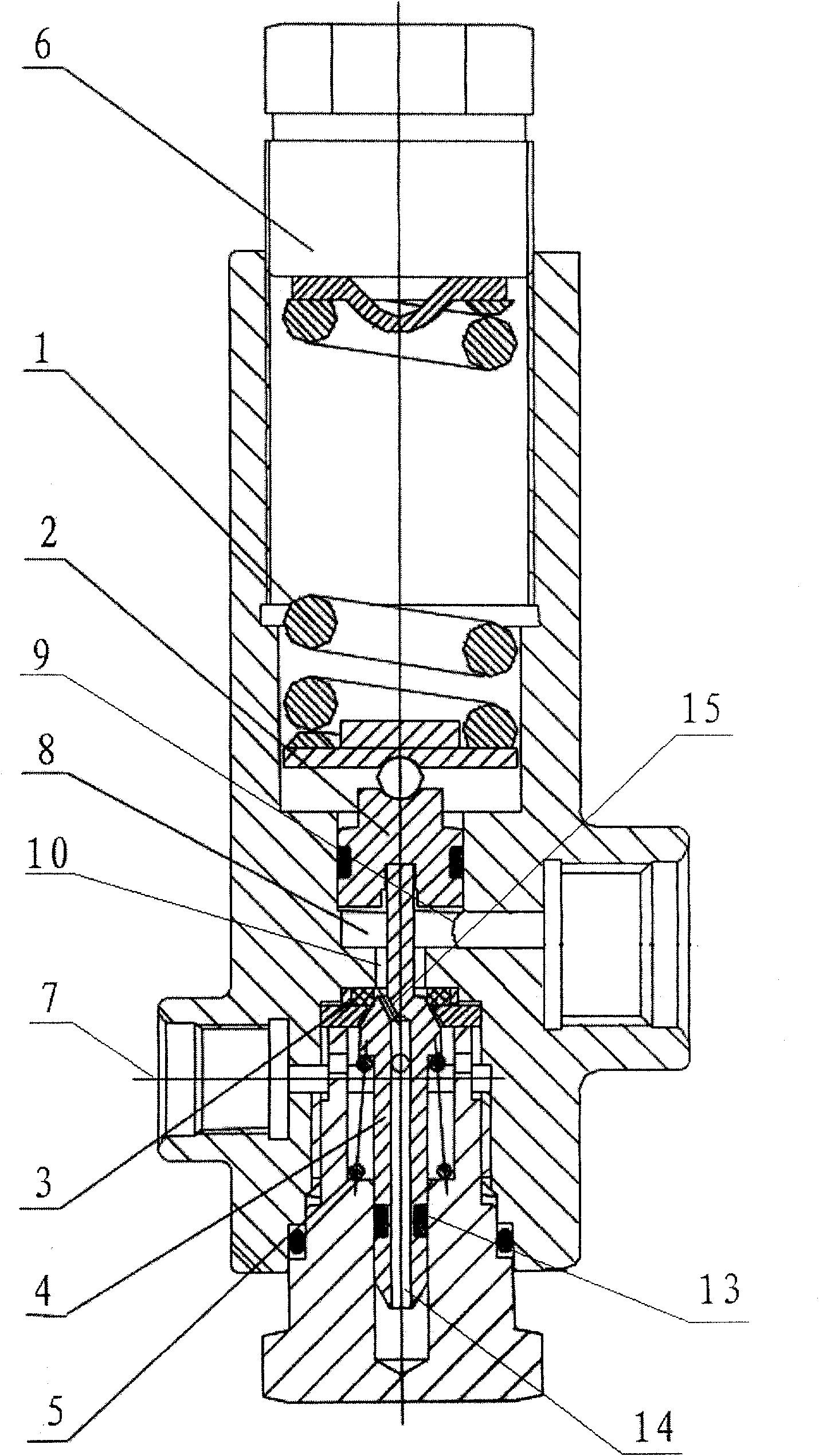

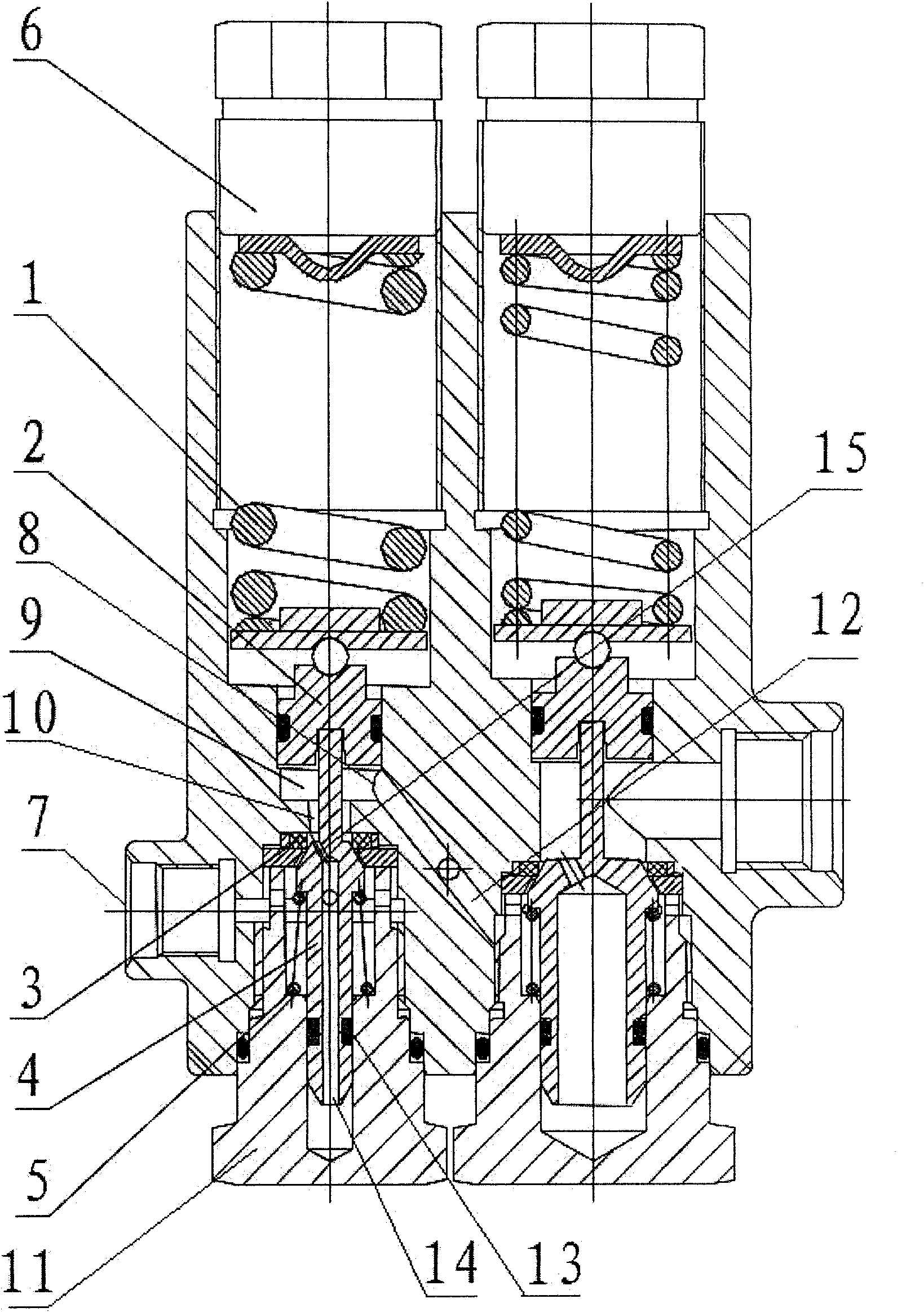

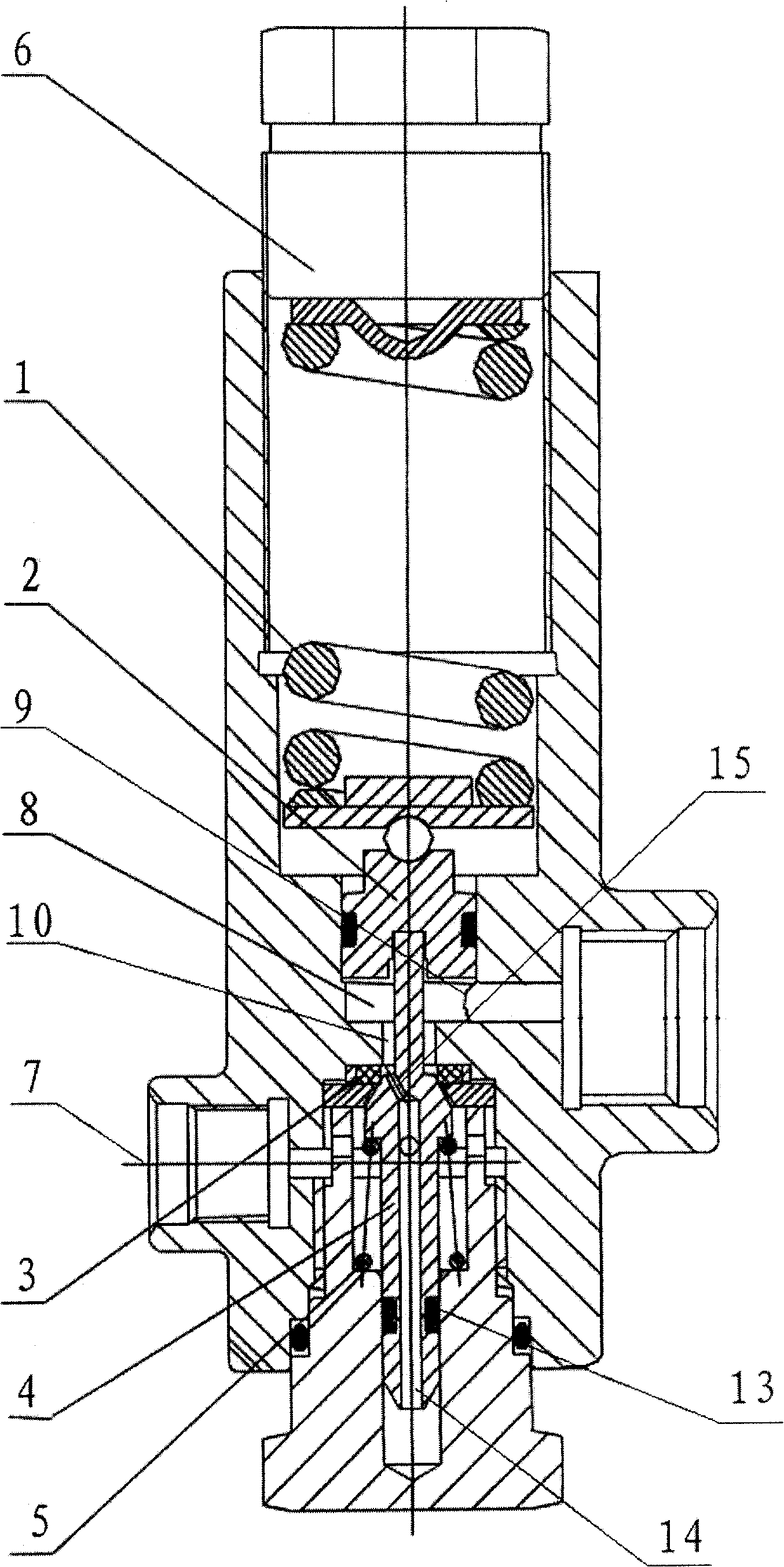

[0013] like figure 1 In the air pressure decompression device shown, a piston cavity is arranged in the housing of the decompression device, and a decompression spring chamber and a ejector rod chamber are connected to the coaxial line at both ends of the piston cavity, and a piston 2 is installed in the piston cavity. The compression spring chamber is equipped with a decompression spring 1 whose inner end is pressure-fitted with the piston 2. The outer end of the decompression spring is press-fitted with a pressure-regulating nut 6 which is helically assembled on the outdoor port of the decompression spring. The top is equipped with a push rod 4 whose inner end is press fit with the piston. The push rod is equipped with a preload spring 5 that drives the push rod to press the piston. The valve seal structure is composed of the dynamic sealing surface and the static seal at the passage 10, the ejector rod chamber is a sealed space, the ejector rod chamber is connected with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com